UVDTF Printing – Ultimate Guide to the Top 5 Most Asked Questions

Table of Contents

Top 5 Questions About UVDTF Printing Answered

Introduction to UVDTF Printing

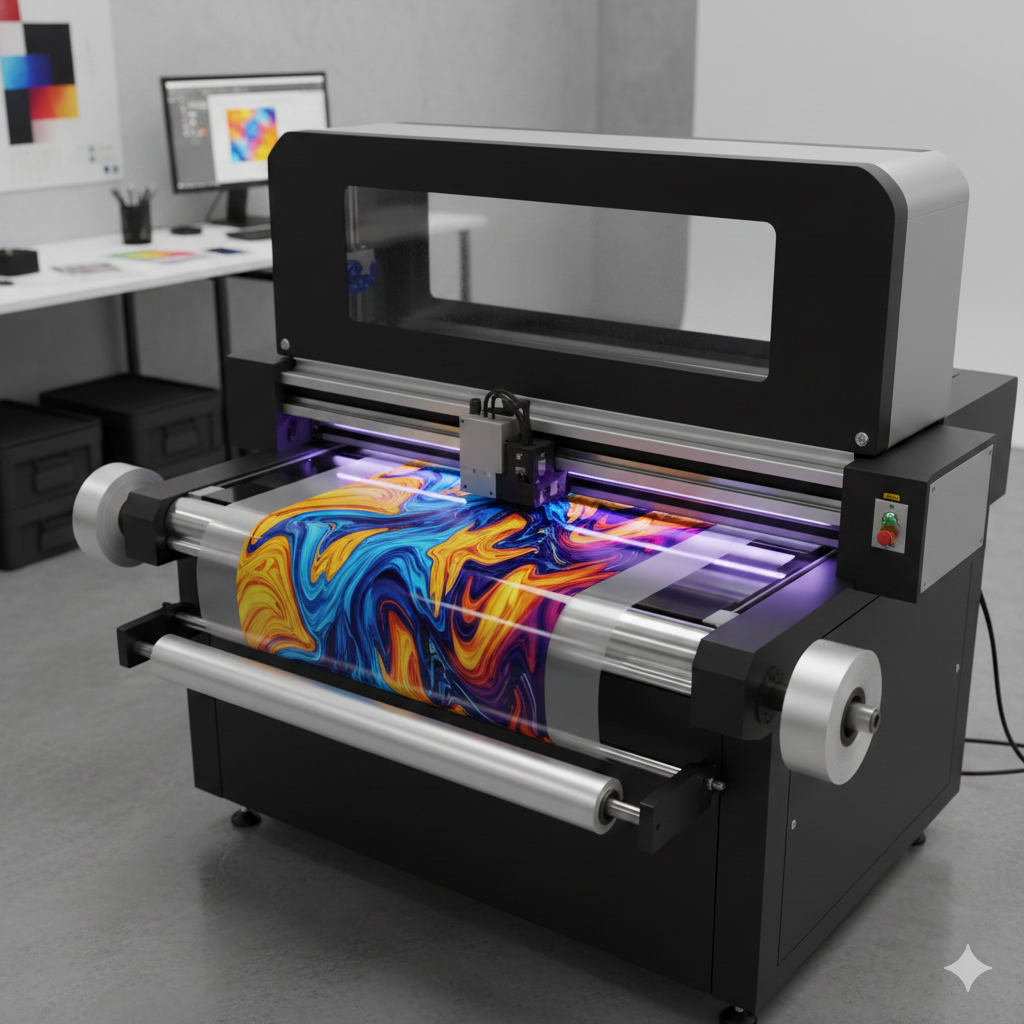

Over the last few years, many businesses and creators have shifted to UVDTF Printing because it produces a glossy, textured print that looks premium on almost any surface. From phone cases to stainless steel bottles, shops are using this new method to add durability and shine without complicated tools. People ask many questions about how it works, how it differs from DTF, and whether the equipment is expensive.

This blog answers the top five questions in a simple, friendly way with practical examples.

Question 1: What is UVDTF Printing?

UVDTF Printing stands for Ultra-Violet Direct-to-Film printing. It uses UV inks to print on a special film and then transfers that printed layer onto another surface.

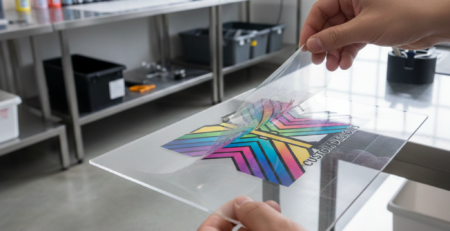

Unlike regular UV printing, the print does not happen directly on the object. Instead, the artwork is printed on film first, then peeled and applied.

For example, a gift shop can print 50 custom name stickers on one sheet and transfer them later on bottles, mugs, acrylic keychains, laptop covers, etc. It offers convenience because the printing step and the pasting step can happen at different times and locations.

Simply put:

➡ UV printing + Transfer film = UVDTF Printing

Question 2: How Does the UVDTF Process Work?

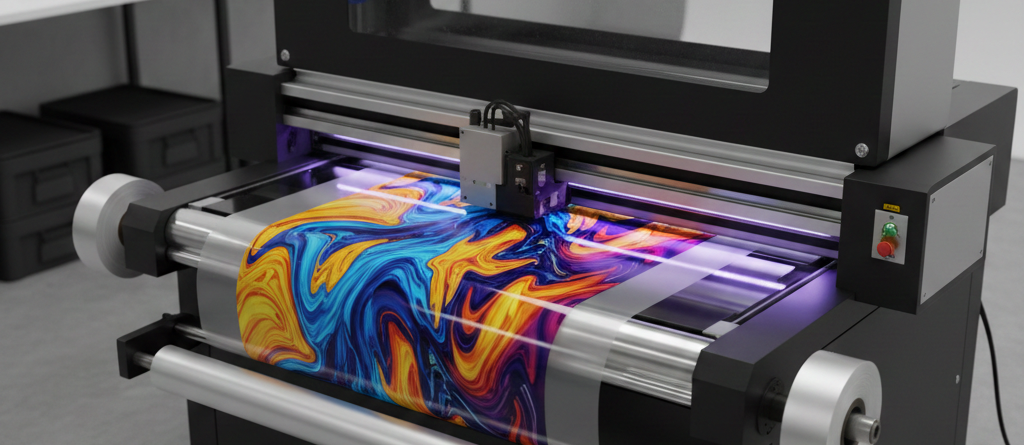

The process may sound technical, but it’s actually simple once you get familiar:

- The design is printed on an A+B transfer film with UV ink.

- The printer adds a layer of varnish for shine and durability.

- The film is cut, peeled, and pressed onto the object.

- The transparent layer is removed, leaving the print behind.

There is no need for heat press or drying time. Once transferred, the sticker bonds instantly with the surface.

Anyone starting in UVDTF Printing usually follows a small workflow:

- Prepare artwork

- Print on film using UV printer

- Apply to product

- Remove the carrier film

The best part is that even beginners can handle customer orders in the first week because the process is straightforward.

Question 3: What Makes UVDTF Different from DTF?

People often compare UVDTF to DTF, even though they are designed for different materials. Here’s a quick real-life comparison:

| Feature | UVDTF Printing | DTF Printing |

|---|---|---|

| Best for | Hard objects (plastic, metal, wood, ceramic, glass) | Fabric (cotton, polyester, blends) |

| Feel | Glossy, 3D texture | Soft fabric-like |

| Adhesion | Extremely strong | Wash-resistant |

| Equipment | UV Printer | DTF Printer + Powder + Curing |

So, if you’re customizing apparel, DTF is still the winner.

But for hard-surface gifts, branding merchandise, or décor items, UVDTF Printing gives a premium glass-like finish that DTF cannot match.

Question 4: What Equipment is Needed for UVDTF?

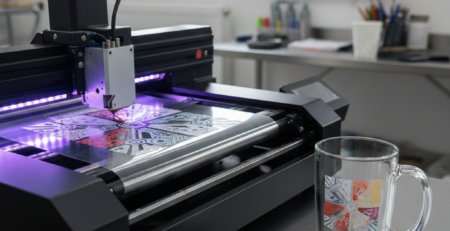

To start UVDTF Printing, you don’t need a huge workshop. Basic setup includes:

- UV DTF Printer

- UV Ink

- A+B Transfer Films

- Software for printing (like MainTop/Photoprint)

- Basic cutting tools

Those who want to explore equipment can check these products on DTFshop.in mentioned here as helpful examples, not for promotion:

🔹 Mini UV DTF Printer – Desktop Model

🔹 UV DTF Inks (CMYK + White + Varnish)

A small business selling custom gifts can start with a mini model, while a large company making thousands of brand stickers may need a bigger format.

Question 5: What Are the Benefits and Applications?

People love UVDTF Printing because it is profitable without high effort. These are the biggest benefits:

✔ Works on almost all hard surfaces

✔ No lamination or heat press required

✔ Perfect for small or bulk jobs

✔ Gives raised glossy texture customers love

✔ Fast turnaround time

Some practical applications:

- Brand logo stickers for water bottles

- Names on mobile covers

- Customized acrylic keychains

- Award trophies and gift boxes

- Toolkit and hardware labels

- Home décor items

- Resin crafts

A small print business shared that after switching to UVDTF Printing, they began selling personalized corporate gift sets during the festive season and doubled revenue simply because the results looked premium without high overhead.

Conclusion

UVDTF Printing has become popular because it delivers modern, glossy, durable output across many industries. It allows both beginners and professionals to work quickly without complicated tools. If your current setup is DTF-only, adding UVDTF gives you the power to serve new markets like corporate gifts, branding services, custom décor, and event merchandise.

With its easy workflow and high demand, UVDTF is not another trend — it’s a long-term opportunity for print entrepreneurs.

External References + Credits

Helpful resources while preparing this guide include:

- Fespa.com – Industry insights on UV printing

- PrintIndustry.com – Real-world case studies in digital printing

- InkJetInsights.com – Ink and substrate testing comparisons

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT