1. UVDTF Printing Advantage: Why Choose It Over Other Printing Methods

Table of Contents

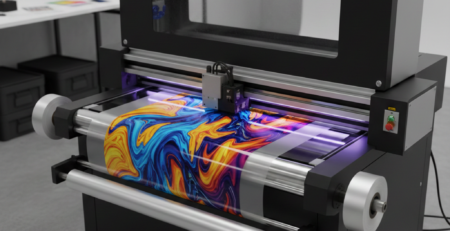

Introduction to UVDTF Printing

UVDTF Printing is changing the way businesses and creators think about surface printing. It is clean, fast, and flexible. Unlike older printing styles, UVDTF Printing allows designs to be transferred easily onto many hard surfaces without heat or heavy machines.

In simple words, This Printing uses UV-cured ink printed on a special film. The design is then transferred directly onto the product. The result is a strong, bright, and long-lasting print. This method is now popular among small workshops, branding companies, and custom product makers.

Many people switch to UVDTF Printing because it saves time and reduces waste. It also works well for short runs and custom jobs. If you want clean results without complex steps, this method stands out.

Overview of Common Printing Methods

Before choosing this Printing, it helps to understand other printing methods commonly used today.

Screen Printing

Screen printing is old and reliable. It works well for bulk orders. But it needs multiple screens, setup time, and space. It is not ideal for small quantities or frequent design changes.

Heat Transfer Vinyl (HTV)

HTV is popular for apparel. But it needs heat presses and does not work well on hard surfaces. Over time, vinyl may peel or crack.

Direct to Garment (DTG)

DTG prints directly on fabric. The print quality is good, but machines are costly. Ink maintenance is also a challenge.

Sublimation Printing

Sublimation is great for polyester and coated products. But it cannot print on all materials. Color accuracy also depends on surface coating.

Compared to these, UVDTF Printing offers more freedom. It works on glass, metal, plastic, wood, acrylic, and more.

Key Advantages of UVDTF

UVDTF Printing has several clear advantages that make it a smart choice.

No Heat Required

Unlike sublimation or HTV, UVDTF Printing does not need heat. This makes it safer for delicate surfaces and easier to use.

Strong Adhesion

The UV ink bonds firmly to surfaces. Prints do not fade, peel, or crack easily.

Wide Material Compatibility

You can apply UVDTF Printing on bottles, signboards, phone covers, panels, and promotional items.

Bright and Sharp Prints

UV ink gives rich colors and clear details. Even small text looks sharp.

Low Setup Cost

There are fewer tools involved. You don’t need heavy presses or expensive molds.

For example, small businesses often use UV DTF Transfer Film Roll to create custom branding items quickly without large investments.

Direct Comparisons with Alternatives

When compared directly, UVDTF Printing often wins on flexibility.

UVDTF Printing vs Screen Printing

Screen printing is good for bulk. But UVDTF Printing is better for small orders and customization. No screens. No drying time.

UVDTF Printing vs Sublimation

Sublimation needs coated surfaces. UVDTF Printing works on almost any hard surface. This gives more freedom in product selection.

UVDTF Printing vs Vinyl Stickers

Vinyl stickers sit on top of surfaces. UVDTF Printing feels like part of the product. It looks more premium and lasts longer.

Using tools like UV DTF Ink Set ensures color stability and long-term durability in daily-use items.

Ideal Applications and Use Cases

UVDTF Printing fits many industries and daily needs.

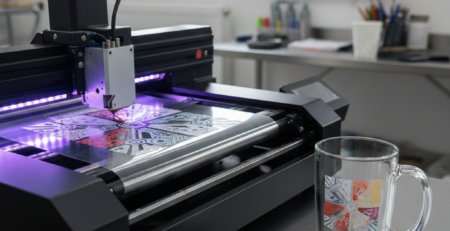

Corporate Branding

Logos on mugs, bottles, and office accessories look clean and professional.

Promotional Products

Perfect for keychains, acrylic boards, awards, and gift items.

Interior Décor

Used on glass panels, wooden boards, and decorative plates.

Small Business Custom Orders

Personalized products with names or short runs are easy to handle.

A common setup includes A3 UV DTF Printer paired with Cold Lamination Film for UV DTF for smooth application and protection.

For better results, professionals also recommend UV DTF Adhesive Film for clean transfers without bubbles.

Practical Tips from Real Use

- Always clean the surface before applying the transfer.

- Use even pressure during application.

- Allow the ink to fully cure before handling.

- Store films in a cool, dry place.

These small steps improve final output and reduce rework.

Conclusion and Call to Action

UVDTF Printing is a modern solution for today’s printing needs. It is simple, flexible, and cost-effective. Compared to older methods, it saves time and expands creative options.

If you work with hard surfaces or need fast customization, UVDTF Printing is worth considering. It fits both beginners and experienced professionals.

Explore the right materials, test on sample products, and see how UVDTF Printing can improve your workflow.

Product Suggestions (Blue Color)

- UV DTF Transfer Film Roll

- UV DTF Ink Set

- A3 UV DTF Printer

- Cold Lamination Film for UV DTF

- UV DTF Adhesive Film

External References + Credits

Helpful reading sources:

- PrintIndustry.com – General printing trends

- Fespa.com – UV printing technology insights

- InkJetInsights.com – Ink and printhead analysis

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply