UVDTF Printing – Ultimate Reason Why Indian Printers Prefer It for T-Shirts

Table of Contents

What is UVDTF Printing and Why It Matters?

Indian garment printing has changed fast in recent years. Buyers want T-shirts with strong colors, fast turnaround, and long-lasting prints. Many printers struggled to meet this demand with traditional methods. That’s where UVDTF Printing stepped in. It gives sharp colors, strong durability, and works on almost every fabric making it a game-changer for T-shirt businesses.

Introduction to UVDTF Printing

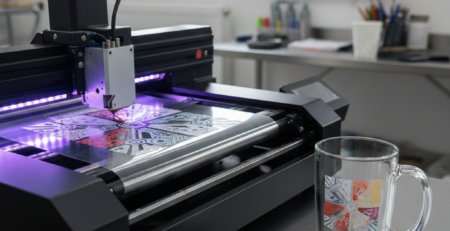

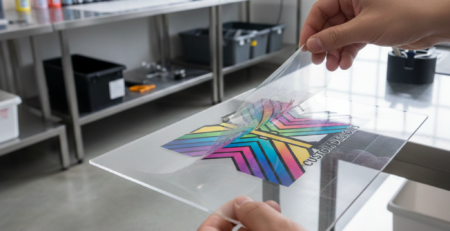

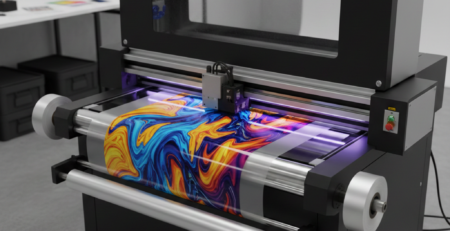

To put it simply, UVDTF Printing is a type of UV transfer printing where a design is printed on a special film and then transferred onto fabric using adhesive and UV light curing. Unlike heat transfer vinyl or screen printing, it does not crack or fade easily. Even small printing shops in India are adopting this method because it reduces effort but increases output.

Overview of T-Shirt Printing Challenges in India

Indian printers often face issues like:

- Heat press burn marks on polyester

- Cracking prints during washing

- Expensive production for small quantities

- Ink wastage and curing problems

- High setup cost for screen printing plates

Because of these real-world problems, many printers began searching for a better solution that delivers both quality and speed. That led to growing interest in UVDTF Printing.

What is UVDTF Printing?

In technical terms, UVDTF Printing uses UV inks printed onto a film coated with adhesive. When transferred onto fabric, it bonds strongly with the fibers using UV curing. You don’t need heavy pressure or high heat, making it ideal for soft fabrics and premium T-shirts.

Some printers compare it to DTF, but the print quality and stretch performance tend to be stronger due to UV adhesion layers. ResearchGate also notes UV curing provides higher scratch resistance compared to water-based inks used in other methods.

Key Advantages of UVDTF for T-Shirts

✔ Vibrant colors and durability

UVDTF prints have a thick, glossy finish that shines even after 50+ washes. Colors do not dull or bleed. Teens and streetwear customers especially prefer this bold look. Many exporters use it for premium collections.

✔ Fast production speed

No long setup. No pretreatment. No drying time. A printer can finish multiple T-shirt orders within hours. A small shop with one machine can handle festival-season demand easily.

✔ No pre-treatment needed

Unlike DTG printing where fixing solutions are required, fabrics in UVDTF Printing don’t need pre-coating. Just peel and press, saving materials and labor.

Why Indian Printers Prefer UVDTF

✔ Cost-effectiveness for small batches

For 1–50 PCS orders, UVDTF is cheaper than screen printing. There’s no plate cost or preparation time, which makes it great for customized orders — birthdays, team jerseys, school clubs, and corporate gifting.

✔ Versatility on fabrics

Cotton, polyester, denim, hoodies, lycra, and blends — all work perfectly. This flexibility allows one printer to take multiple types of jobs.

✔ High demand in local markets

Trendy graphics, shiny prints, and name customization are popular in youth markets. Print shops in cities, colleges, and malls report much higher order values after adopting UVDTF Printing.

UVDTF vs Traditional Methods (DTF, DTG, Screen Printing)

| Feature | UVDTF | DTF | DTG | Screen Printing |

|---|---|---|---|---|

| Wash durability | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Best for | Small & custom orders | Bulk & small | Premium cotton | Very large runs |

| Speed | Very fast | Fast | Slow | Medium |

| Color impact | Very vibrant | Medium | Natural | Strong |

| Fabric flexibility | All fabrics | Most | Mostly cotton | Most |

Overall, UVDTF Printing offers the best balance of speed, cost, and visual appeal — which is why many printers switch to it even if they already use DTF or screen printing.

Implementation Tips for Indian Printers

To get the best results:

- Maintain a dust-free transfer table

- Use high-quality transfer film and adhesive

- Do not over-cure with UV light

- Peel slowly to avoid lifting corners

- Choose premium T-shirt blanks for premium results

Many Indian shops use accessories such as:

- UVDTF A3 Transfer Film

- UV DTF Glossy Inks

- Heat Press Machine Pro

- UV Lamination Sheets

- UV Roll Media 30cm

These help printers reduce mistakes and speed up production.

Success Stories or Case Studies

- A small shop in Surat switched from DTG to UVDTF Printing and reduced rework by 60% because there were no print cracking complaints.

- A startup in Bangalore used UV transfers for custom name T-shirts and saw nearly 3× profit during college fest season.

- A Tiruppur exporter started adding layered UV prints for “premium fashion series” and now sells at double the rate compared to regular DTF tees.

These are not rare cases. Hundreds of Indian printers share similar stories at events covered by Fespa.com and PrintIndustry.com.

Conclusion and Call to Action

UVDTF Printing is not just another trend. It solves real challenges — speed, quality, wash resistance, and fabric versatility. For Indian printers planning to expand or start a T-shirt business, this technique can create higher profits with lower setup cost.

If you are growing your garment printing business, this is the right time to experiment and see real results.

🔗 Product Suggestions

- UVDTF A3 Transfer Film

- UV DTF Glossy Inks

- Heat Press Machine Pro

- UV Lamination Sheets

- UV Roll Media 30cm

🔗 External References + Credits

Information inspired from industry knowledge and supported by:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply