1. White Ink Mastery: How to Handle White Ink Settling Issues

Table of Contents

Introduction to White Ink Settling

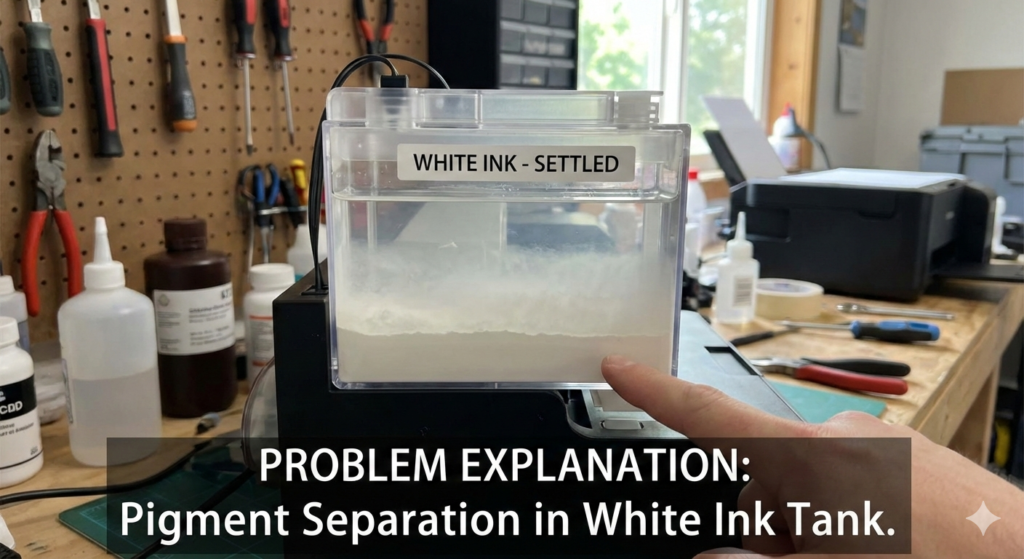

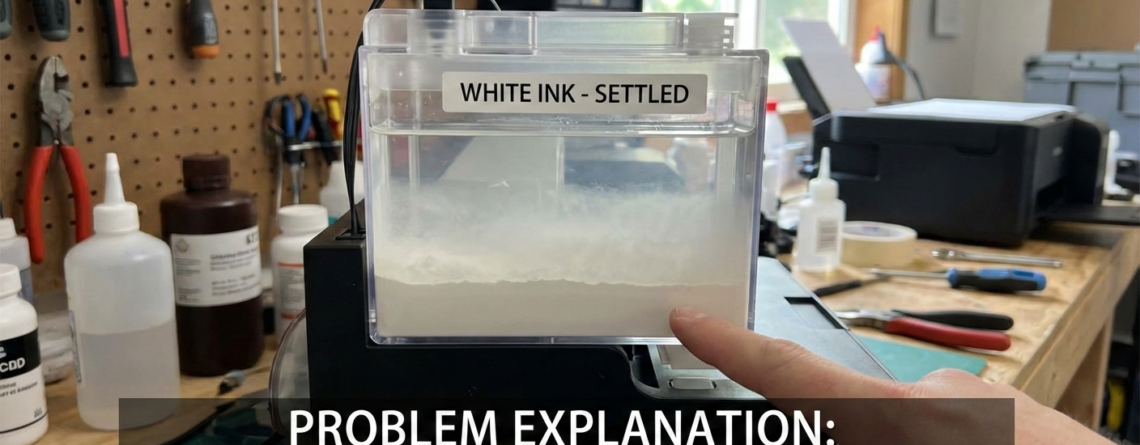

White Ink is essential in modern printing, especially in DTF, UV, and textile printing. It helps prints pop on dark and colored surfaces. But anyone who works with this Ink knows one common problem settling.

It contains heavy pigments. These pigments sink to the bottom when the printer is idle. If ignored, settling can clog print heads, cause uneven prints, or damage the system.

This guide explains White Ink settling in a simple way. You’ll learn why it happens, how to prevent it, and how to fix it step by step. These tips come from real workshop experience, not theory.

Common Causes of Settling

It behaves differently from CMYK inks. Here’s why settling happens:

1. Heavy Pigment Content

It uses titanium dioxide. It’s heavier than normal color pigments. Gravity pulls it down fast.

2. Printer Idle Time

If your printer sits unused for a day or two, White Ink starts separating.

3. Poor Ink Circulation

Some printers lack automatic stirring or circulation systems.

4. Cold Temperature

Low temperatures make Ink thicker, increasing settling speed.

5. Low-Quality Ink

Cheap White Ink settles faster and creates lumps.

According to studies shared on ResearchGate, pigment density and viscosity are the biggest contributors to ink separation in industrial printing systems.

Prevention Techniques

Preventing White Ink settling is easier than fixing it later.

Daily Printer Shake

Gently shake ink tanks every morning. This takes less than one minute.

Use Auto Circulation

If your printer supports circulation, keep it ON at all times.

Print Small Jobs Daily

Even a small test print helps keep White Ink moving.

Maintain Room Temperature

Ideal temperature: 20–25°C. Cold rooms increase settling.

Buy Trusted Ink

Stable Ink reduces clogging and print failures.

FESPA also highlights regular ink movement as a key maintenance practice for ink systems.

Step-by-Step Troubleshooting

If this Ink has already settled, follow these steps:

Step 1: Stop Printing

Never force prints with settled Ink. It can damage the head.

Step 2: Manual Agitation

Remove the ink bottle and shake gently for 30–60 seconds.

Step 3: Clean Ink Lines

Use cleaning solution to flush the lines if ink looks uneven.

Step 4: Perform Nozzle Check

Look for missing lines or faded white areas.

Step 5: Head Cleaning

Run only one or two cleaning cycles. Over-cleaning causes waste.

InkJetInsights recommends minimal cleaning cycles combined with manual agitation for best results.

Best Practices for Maintenance

Good habits save money and printers.

- Shake White Ink bottles daily

- Clean caps and dampers weekly

- Keep printer covered when idle

- Avoid mixing old and new White Ink

- Replace filters regularly

Real-life example:

A DTF workshop in Surat reduced head clogs by 60% just by shaking ink bottles every morning and printing a test strip daily.

Recommended Tools and Products

The right tools make Ink maintenance easier.

Use quality inks, cleaning fluids, and maintenance kits. Reliable suppliers matter.

Recommended items commonly used by professionals:

- DTF White Ink – Pro Grade

- DTF Printer Cleaning Solution

- Ink Agitator for DTF Ink Tanks

- DTF Print Head Maintenance Kit

- White Ink Circulation Pump System

These products are widely used in Indian DTF setups and help reduce settling-related downtime.

Frequently Asked Questions

Why does White Ink settle faster than other inks?

This Ink contains heavier pigments. Color inks use lighter dyes.

How often should I shake White Ink?

Daily. Even if you print every day.

Can settled White Ink damage print heads?

Yes. Thick ink blocks nozzles and causes overheating.

Is automatic circulation enough?

It helps, but manual checks are still important.

How long can this Ink sit unused?

Not more than 24–48 hours without agitation.

Conclusion and Final Tips

This Ink settling is common, but it’s manageable.

Understand the nature of White Ink. Keep it moving. Maintain temperature. Use trusted products. Small daily habits prevent big repair costs.

Think of Ink like milk. If it sits, it separates. Shake it, use it, and store it properly.

A little care keeps your prints sharp, bright, and professional.

Product Suggestions (Blue Color)

- DTF White Ink – Premium Quality

- DTF Ink Circulation System

- DTF Cleaning Liquid

- DTF Maintenance Tool Kit

External References + Credits

Helpful learning resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT