DTF Printing 7 Powerful ROI Truths: Profitable vs Risky Sublimation Business

Table of Contents

Introduction

If you are planning to start a custom printing business, this question always comes first:

DTF Printing or Sublimation which one gives better return on investment?

Many small print shops fail not because of lack of orders, but because they choose the wrong printing method for their market. ROI is not just about machine price. It is about fabric flexibility, repeat orders, production speed, and long-term profit.

In this article, we break down DTF Printing vs Sublimation business using real numbers, practical examples, and simple logic. No hype. No selling talk. Just facts.

Overview

DTF Printing (Direct to Film) is a modern method where designs are printed on a special film, coated with adhesive powder, heat cured, and then transferred to fabric using a heat press.

The biggest advantage of this printing is flexibility. You can print on cotton, polyester, blends, denim, hoodies, caps, and even dark fabrics.

A typical DTF setup includes a printer, PET film, DTF inks, adhesive powder, and a heat press. Many small businesses start with compact setups like

DTF Printers and upgrade later.

This Printing works well for:

- T-shirts

- Hoodies

- Corporate uniforms

- Sportswear

- Custom merchandise

Overview of Sublimation Printing

Sublimation printing uses heat to convert ink into gas that bonds with polyester fabric or polymer-coated surfaces.

It is a clean process with no extra powder or film handling. However, sublimation has a major limitation: only light-colored polyester fabrics work well.

Sublimation is popular for:

- Polyester sports jerseys

- Mugs and tiles

- Mouse pads

- Promotional gifts

If your local market demands cotton garments, sublimation becomes restrictive.

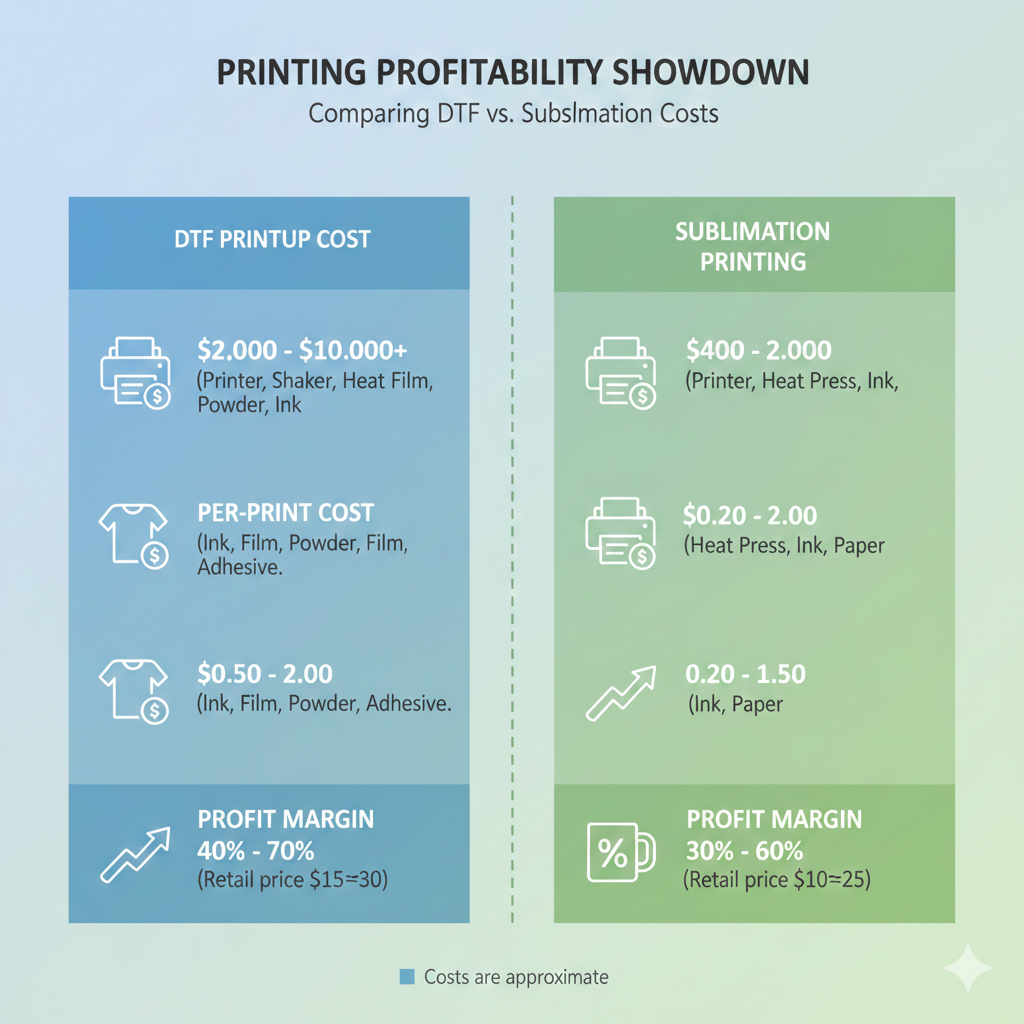

Initial Startup Costs Comparison

Startup cost plays a big role in ROI.

DTF Printing Setup (Entry Level):

- DTF Printer

- Heat Press

- Curing method

- Consumables

Typical investment: ₹1.5 – ₹3.5 lakhs

A setup using items like

DTF Ink and

DTF PET Film

can be expanded later without replacing the printer.

Sublimation Setup:

- Sublimation printer

- Heat press

- Basic inks and paper

Typical investment: ₹70,000 – ₹1.5 lakhs

Sublimation looks cheaper at the start, but ROI depends on product range.

Per-Print Production Costs

Let’s compare average cost per T-shirt.

DTF Printing Cost Per Print:

- Ink: ₹20–30

- Film & powder: ₹25–35

- Electricity & labor: ₹10

Total: ₹55–75 per print

Sublimation Cost Per Print:

- Ink: ₹15–20

- Paper: ₹10

- Polyester T-shirt cost is higher

Total: ₹35–50 per print

DTF Printing costs more per print, but allows higher selling price.

Key Operational Differences (Fabrics, Durability, Scalability)

Fabric Compatibility

- DTF Printing: Cotton, poly, blends, dark colors

- Sublimation: Polyester only, light colors

Durability

- DTF Printing transfers last 40–60 washes

- Sublimation becomes part of fabric, very durable

Scalability

- DTF Printing scales better for mixed orders

- Sublimation is limited to specific SKUs

If you plan bulk corporate orders, DTF Printing offers more control.

Revenue Potential Breakdown

Let’s talk real numbers.

DTF Printing Average Selling Price:

- T-shirt: ₹399–699

- Hoodie: ₹899–1499

Sublimation Average Selling Price:

- T-shirt: ₹349–499

DTF Printing allows premium pricing due to fabric choice and print opacity.

Profit Margins Table

| Printing Type | Avg Cost | Avg Selling Price | Profit per Piece |

|---|---|---|---|

| DTF Printing | ₹65 | ₹550 | ₹485 |

| Sublimation | ₹45 | ₹425 | ₹380 |

Higher margin does not always mean higher ROI, but it helps recover investment faster.

ROI Calculation Scenarios

DTF Printing Example:

- Daily prints: 20

- Monthly prints: 600

- Avg profit: ₹480

Monthly profit: ₹2,88,000

Sublimation Example:

- Daily prints: 20

- Monthly prints: 600

- Avg profit: ₹380

Monthly profit: ₹2,28,000

This Printing pulls ahead if demand exists.

Break-Even Analysis

DTF Printing Break-Even:

- Investment: ₹2.5 lakhs

- Monthly profit: ₹2.8 lakhs

- Break-even: 1–2 months

Sublimation Break-Even:

- Investment: ₹1 lakh

- Monthly profit: ₹2.2 lakhs

- Break-even: 1 month

Sublimation recovers faster but plateaus sooner.

Real-World Case Studies

A local print shop in Delhi started with sublimation for sports jerseys. Orders were seasonal. They later added this Printing and started printing cotton uniforms and event merchandise.

Result:

- 35% increase in monthly revenue

- More repeat customers

- Less dependency on polyester fabric availability

This pattern is common across small Indian print shops.

Risks and Challenges

DTF Printing Risks:

- Improper powder curing

- Film quality issues

- Learning curve

Using reliable consumables like

DTF Powder

and Heat Press Machines

reduces waste.

Sublimation Risks:

- Limited fabric options

- Price competition

- Lower order diversity

Recommendation Criteria

Choose DTF Printing if:

- You want flexibility

- You plan to serve multiple garment types

- You aim for higher long-term ROI

Choose sublimation if:

- You only print sportswear

- You want low initial investment

- Your market is polyester-focused

Conclusion with Action Steps

DTF Printing is not perfect, but it is versatile. Sublimation is simple, but limited.

If you want steady growth, broader customers, and better pricing control, DTF Printing offers stronger long-term ROI.

Action Steps:

- Study your local garment demand

- Start small with DTF Printing

- Control costs with quality consumables

- Scale once orders stabilize

Product Suggestions (Blue Color)

(All products referenced from DTFshop.in)

External References + Credits

Helpful industry resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply