UVDTF Printing Revolution: New Technologies Transforming UVDTF Printing in 2025

Table of Contents

Introduction to UVDTF Printing

UVDTF Printing is no longer a niche technology. In 2025, it has become one of the fastest-growing printing methods for decorators, signage makers, and custom product businesses. Many small print shops are shifting from traditional vinyl and solvent printing to UVDTF Printing because it is faster, cleaner, and more versatile.

The biggest reason for this growth is technology. New machines, smarter software, and better inks are solving old problems like color inconsistency, slow curing, and material limitations. If you work in printing or product branding, understanding these changes will help you stay competitive.

This article explains what UVDTF Printing is, what’s new in 2025, and how these advancements affect real print businesses.

What is UVDTF Technology?

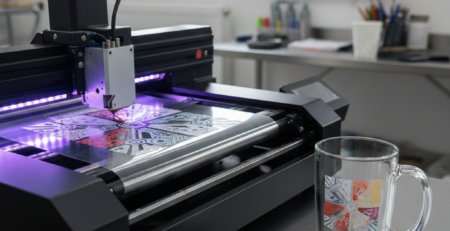

UVDTF Printing stands for UV Direct to Film printing. Instead of printing directly on the final surface, the design is printed on a special film using UV-curable ink. The printed film is then transferred onto materials like glass, metal, plastic, wood, leather, or acrylic.

Unlike heat-based transfers, UVDTF Printing uses UV light to instantly cure the ink. This makes the print durable, scratch-resistant, and waterproof. There is no heat press required, which reduces material damage and energy usage.

For example, many custom bottle manufacturers now use UVDTF Printing to brand glass bottles without worrying about cracking or color fading.

Key Advancements in 2025

The year 2025 brings practical upgrades rather than flashy marketing features. These improvements focus on speed, consistency, and sustainability.

Print shops using machines like the A3 UVDTF Printing Machine from DTFshop.in are seeing better output quality because of these changes. Let’s break down the major advancements.

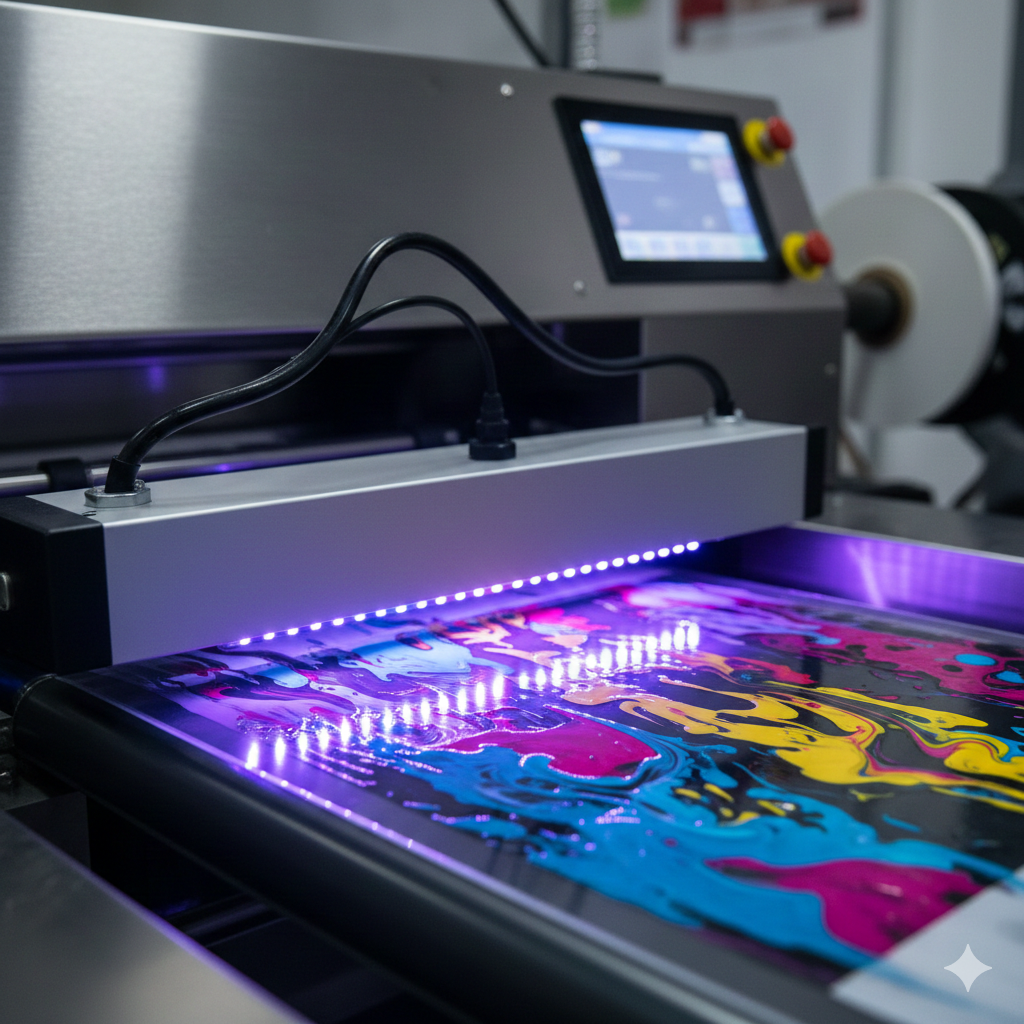

LED UV Curing Innovations

Older UV lamps were powerful but problematic. They generated heat, consumed more electricity, and required frequent replacement. In 2025, LED UV curing has become the standard for UVDTF Printing.

What’s better now?

- Lower power consumption

- Minimal heat generation

- Longer lamp life

- Faster curing speed

This matters when printing on sensitive surfaces like thin plastics or coated wood. LED UV systems cure ink instantly without warping the material.

Many roll-based setups now pair LED curing with tools like the UV DTF AB Film Roll, allowing smooth and consistent curing across long print runs.

AI-Driven Color Management

Color mismatch has always been a headache in printing. In 2025, AI-powered color management systems are reducing trial-and-error work.

Modern UVDTF Printing software now:

- Automatically adjusts ink density

- Predicts color output on different materials

- Corrects color drift during long production runs

This is especially useful for brand work where logo colors must stay exact. For example, when printing multiple batches of acrylic signage, AI color tools ensure every piece matches perfectly.

Research shared on ResearchGate shows that AI-based color correction can reduce ink waste by up to 18%, which directly improves profit margins.

Roll-to-Roll Production Systems

One of the biggest shifts in UVDTF Printing is the move toward roll-to-roll systems. These setups allow continuous printing instead of sheet-by-sheet output.

Benefits include:

- Higher production speed

- Less manual handling

- Better alignment accuracy

Small businesses that started with flatbed systems are now upgrading to compact roll machines. When combined with quality consumables like UV DTF Cold Peel Film, roll-to-roll setups produce cleaner transfers with fewer errors.

This upgrade is especially helpful for sticker manufacturers and promotional product suppliers.

Eco-Friendly Inks and Materials

Sustainability is no longer optional. In 2025, UVDTF Printing inks are becoming more eco-friendly without sacrificing durability.

New UV inks offer:

- Lower VOC emissions

- Better adhesion with thinner ink layers

- Reduced odor

Eco-certified inks now work well with adhesives such as UV DTF Adhesive Glue, ensuring strong bonding while meeting environmental standards.

According to Fespa.com, printers using low-VOC UV inks report improved workplace safety and easier compliance with local regulations.

Benefits for Print Businesses

All these advancements bring real business advantages. UVDTF Printing in 2025 is not just about better prints—it’s about smarter operations.

Key benefits:

- Faster job completion

- Lower power and ink costs

- Less rework due to color errors

- Wider material compatibility

For example, a small signage shop can now handle glass, metal, and wood jobs using one UVDTF Printing setup instead of multiple machines.

Using reliable equipment and consumables from DTFshop.in helps maintain consistent output without increasing complexity.

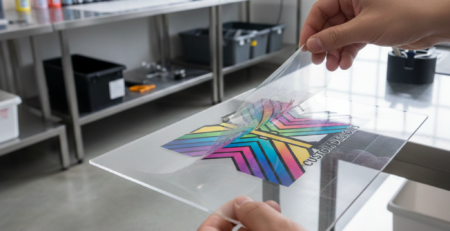

Real-World Applications

UVDTF Printing is being used across many industries in 2025:

- Glass branding: Bottles, jars, trophies

- Retail signage: Acrylic boards, nameplates

- Industrial labeling: Control panels, machine tags

- Customized gifts: Phone cases, notebooks, décor

Many event companies now use UVDTF Printing to create short-run custom items with premium finish and fast turnaround.

PrintIndustry.com highlights that UV-based transfer methods are replacing solvent printing in urban areas due to cleaner operation and faster delivery times.

Future Trends Beyond 2025

Looking ahead, UVDTF Printing will continue to evolve.

Expected trends include:

- Smarter automation with fewer manual steps

- Even thinner ink layers with stronger adhesion

- More recyclable films and liners

- Cloud-based job monitoring

InkJetInsights.com predicts that hybrid UV systems combining direct and transfer printing will become more common, offering maximum flexibility.

Businesses that invest early in adaptable UVDTF Printing technology will be better prepared for these shifts.

Conclusion and Business Tips

UVDTF Printing in 2025 is practical, efficient, and business-friendly. The technology is no longer complex or risky. With LED curing, AI color control, roll-to-roll systems, and eco inks, printers can produce better results with less effort.

Practical tips:

- Start with reliable consumables before upgrading machines

- Use AI color tools to reduce waste

- Test LED curing settings on new materials

- Choose films and adhesives suited to your product type

UVDTF Printing is not about replacing everything overnight. It’s about improving quality step by step while keeping costs under control.

Product Suggestions (from DTFshop.in)

(Products mentioned naturally for understanding usage and workflow.)

External References + Credits

Helpful resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply