White DTF Ink Ultimate Guide: 7 Proven Tips for Smooth Printing

Table of Contents

Introduction to White DTF Ink

White DTF Ink plays a major role in direct-to-film printing. If you print on dark or colored fabrics, the white layer is the base that makes all colors pop. Poor-quality ink can ruin prints, clog print heads, and waste time. Good White DTF Ink gives you clean designs, sharp details, and smooth ink flow.

Many print operators struggle with uneven white layers or frequent head cleaning. In most cases, the problem is not the printer. It is the ink. Choosing the right DTF Ink makes daily printing easier and more stable.

This guide explains what makes a white ink good, how to maintain it, and which options work best for smooth printing results.

Importance of Smooth Printing

Smooth printing is not just about looks. It affects production speed, print life, and printer health.

When White DTF Ink flows evenly:

- Prints look solid and professional

- Colors stay bright on dark fabrics

- Print heads last longer

- Less cleaning is required

Rough or grainy white layers can crack after heat pressing. Uneven ink causes color shifts. Smooth DTF Ink solves these issues and improves consistency across jobs.

In busy print shops, smooth printing saves time and money every day.

Key Factors for Best White Ink

Choosing DTF Ink is not about price alone. You must look at performance factors that matter during long print runs.

High Opacity

Opacity means how well the white ink covers the film. High-opacity White DTF Ink blocks fabric color and creates a strong base layer.

Low-opacity ink looks dull on black shirts. You may need multiple passes, which increases ink use and drying time.

A good white ink should:

- Cover in one or two passes

- Stay bright after curing

- Not turn yellow over time

Low Clogging

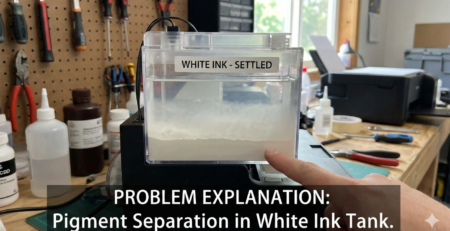

Clogging is the biggest complaint with White DTF Ink. White pigment is heavier than CMYK inks. If the formula is poor, it settles fast.

Low-clogging ink:

- Has stable pigment suspension

- Flows smoothly through nozzles

- Reduces manual cleaning

Daily shaking still helps, but good ink makes maintenance easier.

Consistent Flow

Consistent flow keeps prints even from start to finish. Cheap inks often start strong and weaken mid-print.

Quality White DTF Ink maintains:

- Uniform viscosity

- Stable pressure

- Predictable print density

This is critical for long designs and batch production.

Top Recommended White DTF Inks

Based on user feedback and industry practices, these White DTF Ink products are commonly used for smooth printing.

You can find reliable options at DTFshop.in such as:

- Premium White DTF Ink

- Ultra Opacity White Ink

- Anti-Clog White DTF Ink

- Epson Compatible White Ink

- Pro Series White DTF Ink

These inks are designed for Indian climate conditions and common DTF printers. They focus on smooth flow, clean curing, and reduced maintenance.

Comparison Table of Top Inks

| Feature | Premium White | Ultra Opacity | Anti-Clog White | Pro Series |

|---|---|---|---|---|

| Opacity | High | Very High | High | High |

| Clogging Risk | Low | Medium | Very Low | Low |

| Flow Consistency | Smooth | Smooth | Very Smooth | Smooth |

| Best For | Daily printing | Dark fabrics | Long runs | Professional shops |

| Printer Support | Epson-based | Epson-based | Epson-based | Multiple |

This comparison helps match ink type with workload needs.

Printer Compatibility and Settings

Not all printers behave the same with White DTF Ink. Most DTF setups use Epson-based print heads.

Tips for compatibility:

- Use ink designed for your printer model

- Match ink viscosity with recommended settings

- Avoid mixing different white ink brands

Recommended settings:

- White ink circulation ON if available

- Lower print speed for white layers

- Medium to high white density

Correct settings protect print heads and improve smooth printing.

Maintenance Tips for Smooth Results

Even the best White DTF Ink needs care. Simple habits can prevent problems.

Daily tips:

- Shake white ink bottles gently

- Print a white test strip every morning

- Clean capping station weekly

Weekly tips:

- Inspect dampers and tubes

- Check white ink circulation

- Wipe excess ink buildup

Using clean ink and basic maintenance keeps prints smooth and consistent.

Testing and Troubleshooting Guide

If you face issues, test before changing ink.

Common problems and fixes:

Problem: Grainy white print

Fix: Increase white ink density or slow print speed

Problem: Nozzle clogging

Fix: Use anti-clog White DTF Ink and run head cleaning

Problem: Ink settling

Fix: Shake ink and enable circulation

Problem: White cracking after press

Fix: Reduce ink thickness and adjust curing temperature

Testing small samples saves time and material.

Conclusion and Purchase Advice

White DTF Ink is the foundation of quality DTF printing. Smooth printing depends on opacity, flow, and clog resistance. Choosing the right ink improves print quality and reduces machine stress.

For beginners, start with a stable, low-clog ink. For high-volume shops, focus on flow consistency and pigment stability. Always match ink with your printer and climate.

Reliable White DTF Ink is not an expense. It is a long-term investment in print quality and production efficiency.

Product Suggestions (From DTFshop.in)

- Premium White DTF Ink

- Ultra Opacity White Ink

- Anti-Clog White DTF Ink

- Epson Compatible White Ink

- Pro Series White DTF Ink

External References + Credits

Helpful resources:

- PrintIndustry.com – Printing materials and ink behavior

- Fespa.com – Textile printing trends and ink technology

- InkJetInsights.com – Inkjet ink performance studies

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply