DTF Technology Guide: 9 Easy Ways to Print High-Quality T-Shirts

Table of Contents

Introduction to DTF Technology

DTF Technology has changed how custom T-shirts are printed today. Earlier, printing required different methods for cotton, polyester, or blends. With DTF Technology, the same process works on almost any fabric.

DTF means Direct to Film. The design is printed on a special PET film instead of directly on the fabric. This film is then transferred onto the T-shirt using heat and pressure. The result is a bright, flexible, and durable print.

Small businesses prefer DTF Technology because it is easy to learn and does not require heavy investment. Many home-based printers use it to start custom T-shirt brands. Even print shops now use DTF for short runs and personalized orders.

Benefits of DTF Printing

DTF Technology offers many practical advantages compared to older printing methods.

First, it works on all fabric colors. White, black, cotton, polyester, blends everything is supported.

Second, no fabric pre-treatment is required. This saves time and reduces chemical use.

Third, the prints are stretchable and soft. When you stretch the fabric, the print moves with it instead of cracking.

Another benefit is low wastage. You print only what you need. No screens. No plates.

DTF Technology also allows you to store printed films. You can print designs today and heat press them later when orders come.

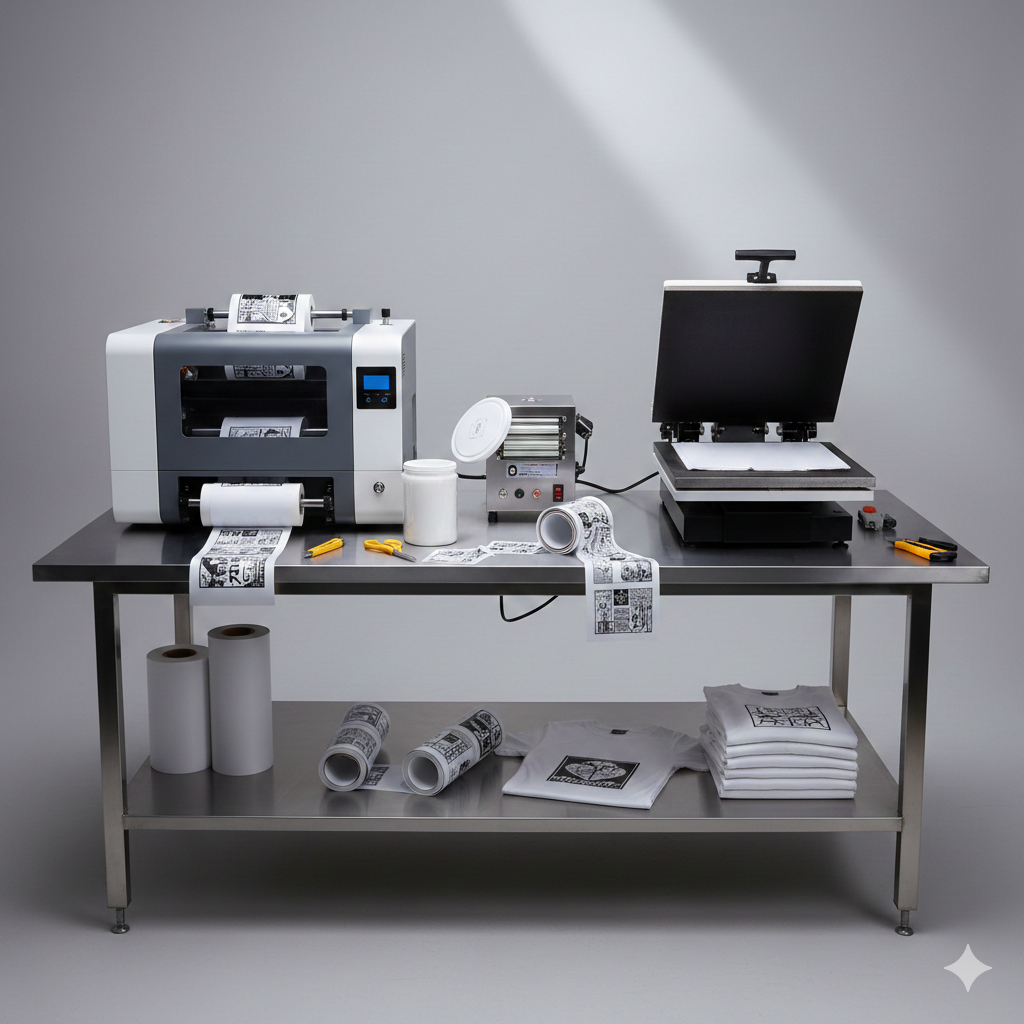

Required Equipment and Materials

To start printing with DTF Technology, you need a few basic tools.

A DTF printer is essential. Many users start with DTF Printers because they are designed specifically for film printing.

Next, you need DTF inks. These include CMYK and white ink. Good ink quality improves color brightness and wash durability. DTF Inks are commonly used for stable white ink flow.

You will also need DTF PET film. This is where the design is printed. Use matte-coated films for better powder adhesion.

Hot melt adhesive powder is applied to the wet ink. It helps bond the print to the fabric. DTF Powder is available in fine, medium, and coarse grades.

Finally, a heat press machine is required. A flat heat press gives even pressure and temperature. Many printers prefer Heat Press Machines for consistent results.

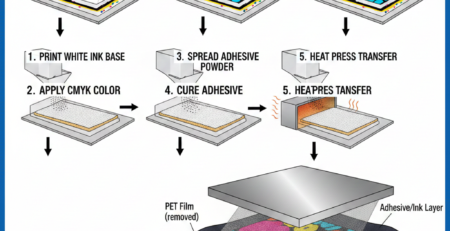

Step-by-Step Printing Process

DTF Technology follows a simple but precise workflow.

Start by preparing your artwork on the computer. Use RIP software to control white ink layers.

Load the PET film into the printer. Print the design on the coated side of the film.

Once printed, apply adhesive powder evenly over the wet ink. Shake off excess powder gently.

Cure the powder using a heat press hover method or curing oven. The powder should melt but not burn.

Place the cured film on the T-shirt. Press it using correct heat and pressure.

After pressing, peel the film. Some films are hot peel, others cold peel. Always check film type.

For better durability, do a second press with parchment paper.

This process makes DTF Technology reliable even for beginners.

Design Preparation Tips

Good design preparation improves print quality.

Always use high-resolution images. Low-quality images look blurry after transfer.

Mirror the design before printing. This ensures correct orientation on the T-shirt.

Use transparent backgrounds instead of solid boxes.

Check color contrast. Bright colors show better on dark fabrics.

Avoid very thin lines. Slightly thicker strokes last longer after washing.

Many experienced users test designs on scrap fabric before final production.

Heat Press Settings

Correct heat press settings are crucial in DTF Technology.

Temperature usually ranges between 150°C to 165°C.

Pressing time is around 10 to 15 seconds.

Pressure should be medium to firm. Too much pressure may flatten the design.

For final pressing, reduce temperature slightly and press for 5 seconds with Teflon or parchment paper.

Always test settings based on fabric type and film brand.

Common Mistakes and Troubleshooting

Many beginners face small issues when using DTF Technology.

If prints peel off after washing, the powder may not be cured properly.

If colors look dull, check ink quality and heat temperature.

White ink clogging is common. Daily printer maintenance helps avoid this.

Uneven prints often result from uneven pressure on the heat press.

Cracking designs usually mean too much heat or over-curing.

Learning from mistakes is part of mastering DTF Technology.

Maintenance and Care Instructions

Daily maintenance keeps your DTF setup running smoothly.

Shake white ink bottles before use.

Clean print heads regularly.

Store PET films in dry areas away from dust.

Keep adhesive powder sealed to avoid moisture.

Clean heat press plates weekly to remove residue.

Proper care improves print quality and machine life.

Conclusion and Next Steps

DTF Technology is one of the easiest ways to start T-shirt printing today. It is flexible, affordable, and beginner-friendly. From custom names to full-color graphics, it handles everything well.

If you are planning to start or upgrade your printing business, DTF Technology is worth considering. Start with basic equipment, practice regularly, and improve step by step.

With the right tools, settings, and care, you can produce professional-quality T-shirts from day one.

Product Suggestions (Blue Color)

DTF Printer

DTF PET Film Sheets

DTF Hot Melt Powder

DTF Textile Inks

Flat Heat Press Machine

External References + Credits

Helpful industry resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply