Discover how new technologies are transforming DTF Printing in 2025, improving quality, speed, and cost efficiency for modern print businesses.

Table of Contents

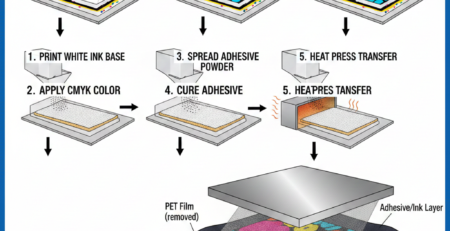

Introduction to DTF Printing

DTF Printing has changed the way custom apparel and textile decoration work. Over the last few years, many small and medium print shops have moved from vinyl and screen printing to DTF Printing because it is flexible, affordable, and easy to scale.

In 2025, DTF Printing is no longer just an alternative. It is becoming a core production method. New technologies are solving old problems like ink wastage, color inconsistency, film handling, and maintenance issues. These upgrades are making DTF Printing faster, cleaner, and more reliable for daily production.

Whether you print t-shirts, hoodies, caps, or tote bags, understanding these new developments can help you make better equipment and workflow decisions.

Current State of DTF in 2025

The current DTF Printing market is more mature than before. Printers are more stable. Inks are more consistent. Films are better coated. Most print shops now use DTF Printing not only for custom orders but also for short-run commercial work.

Print businesses using machines like DTF Printer A3 Pro or DTF Printer A1 High-Speed report fewer breakdowns and improved daily output compared to earlier models from 2022–2023.

Another noticeable change is automation. Powder shaking, curing, and film feeding systems are now more integrated. This reduces manual labor and improves consistency. DTF Printing in 2025 feels less experimental and more industrial.

Key Emerging Technologies

1. Advanced White Ink Circulation Systems

White ink clogging was once the biggest headache in DTF Printing. In 2025, printers use continuous circulation with smart sensors. These systems keep pigment moving even when the machine is idle.

This technology improves print stability and reduces cleaning time. Shops using upgraded machines experience less downtime and lower ink waste.

2. Precision Coated PET Films

New-generation PET films have smoother coatings and better powder adhesion. This results in sharper prints and softer hand feel.

Using quality films like Premium DTF PET Film Roll helps reduce cracking after wash. The difference is noticeable, especially on stretch fabrics.

3. Improved Heat Curing Technology

Older curing methods caused uneven melting or overheating. In 2025, smart curing ovens adjust temperature automatically based on film speed.

Products like DTF Powder Curing Oven now include digital temperature zones. This reduces scorching and ensures proper adhesive bonding.

4. Eco-Friendly DTF Inks

Environmental rules are getting stricter. Ink manufacturers now focus on low-odor, low-VOC formulations. These inks are safer for indoor workspaces and produce vibrant colors without strong chemical smells.

Eco inks also improve wash durability. This makes DTF Printing more acceptable for professional brands and export orders.

Major Industry Trends

Short-Run Production Growth

DTF Printing is perfect for small batch orders. In 2025, brands prefer limited designs instead of mass production. DTF supports fast turnaround with low setup cost.

Hybrid Print Shops

Many shops combine DTF Printing with DTG and sublimation. DTF fills the gap where other methods fail, such as dark fabrics or mixed materials.

Operator Skill Reduction

New machines are easier to run. Touchscreen controls, auto-cleaning cycles, and preset profiles reduce dependency on highly skilled operators.

Using reliable consumables like DTF Hot Melt Powder also improves consistency across different operators.

Benefits and Challenges

Benefits

DTF Printing offers strong color output, fabric flexibility, and cost control. It works on cotton, polyester, blends, leather, and more. The same transfer can be applied later, which helps manage workload.

Maintenance is also easier now. With better ink systems and parts availability, daily operation is smoother.

Challenges

Despite improvements, DTF Printing still requires discipline. Poor storage of films and powders can affect results. Cheap inks may reduce print life. Heat press settings must be accurate.

Another challenge is market saturation. Many shops now offer DTF Printing, so quality and reliability matter more than price.

Future Outlook

The future of DTF Printing looks stable and promising. Industry experts expect better integration with workflow software and color management tools. Automated powder recovery systems may soon become standard.

We may also see compact industrial-grade machines designed for 24/7 operation. Research shared on platforms like ResearchGate suggests ongoing development in adhesive chemistry and pigment dispersion.

DTF Printing will continue to support small businesses while also entering larger manufacturing setups.

Conclusion and Recommendations

DTF Printing in 2025 is smarter, cleaner, and more reliable than ever. New technologies have solved many early issues and made production easier for print businesses of all sizes.

If you are upgrading or starting, focus on machine stability, ink quality, and proper curing equipment. Avoid cutting corners on consumables. Simple discipline and the right tools can give professional results.

DTF Printing is not a trend anymore. It is a long-term solution when done correctly.

Product Suggestions (Blue Color)

- DTF Printer A3 Pro

- DTF Printer A1 High-Speed

- Premium DTF PET Film Roll

- DTF Powder Curing Oven

- DTF Hot Melt Powder

External References + Credits

Helpful resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply