DTF Printing Smarter: How to Reduce Operational Costs Without Compromising Quality

Table of Contents

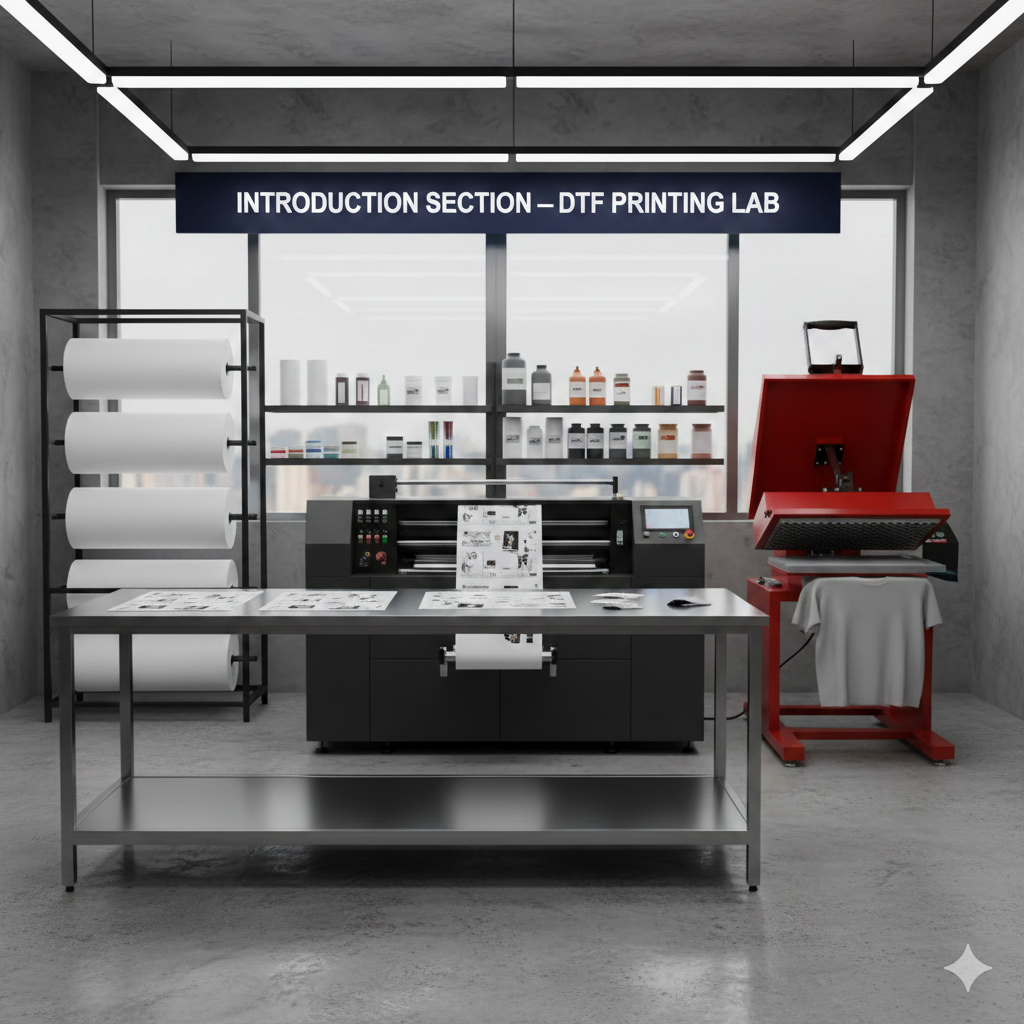

Introduction

DTF Printing has become one of the most popular methods in garment decoration. It is flexible, works on many fabrics, and does not require pre-treatment like DTG. But many print shops struggle with rising costs.

Ink wastage, machine downtime, high power bills, and slow production can eat into profits. The good news is that most of these costs can be controlled with better planning and smarter habits.

This guide explains how to reduce operational costs in DTF Printing without lowering print quality. Everything here is based on real shop practices, not theory.

Understanding Operational Costs

Before reducing costs, you need to know where money is going.

In DTF Printing, operational costs usually come from:

- Ink and consumables

- PET film and powder

- Machine maintenance

- Electricity usage

- Labor time

- Reprints and rejected prints

For example, one misaligned print head can waste ink all day. A poorly stored film can ruin an entire batch. Small issues add up fast.

Tracking daily expenses, even roughly, helps you see problem areas early.

Optimizing Ink and Consumables

Ink is one of the biggest ongoing costs in DTF Printing.

Practical ways to save ink:

- Use correct RIP profiles for your printer

- Avoid over-saturating designs

- Clean print heads regularly to prevent clogging

- Store ink properly to avoid drying

Cheap ink may look like a good deal but often causes nozzle blocks and color inconsistency. That leads to reprints and more waste.

Using reliable consumables like DTF Ink from DTFshop.in and DTF PET Film from DTFshop.in helps maintain consistency and reduces rejects.

Also, shake white ink daily. Settled pigment causes poor white layers and wasted prints.

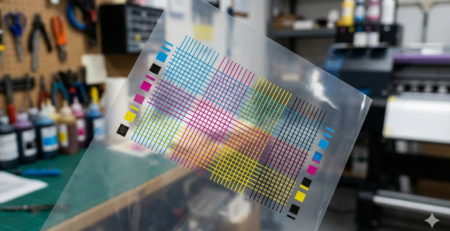

Equipment Maintenance and Efficiency

Machines that are not maintained properly cost more in the long run.

Simple maintenance habits:

- Daily nozzle checks

- Weekly deep cleaning

- Monthly belt and roller inspection

- Keep dust away from electronics

Skipping maintenance saves time today but costs more tomorrow.

Using stable equipment like a DTF Printer from DTFshop.in paired with a quality Heat Press Machine from DTFshop.in improves uptime and reduces breakdowns.

A machine running smoothly prints faster and wastes less ink and film.

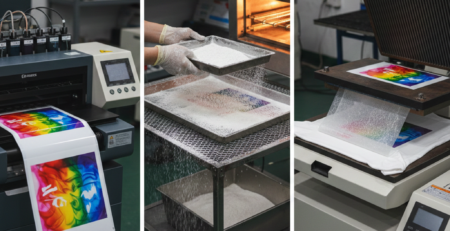

Workflow and Production Optimization

Poor workflow is a hidden cost in DTF Printing.

Common problems include:

- Waiting for files

- Incorrect print settings

- Reprinting due to design errors

- Manual powder spreading

Improve workflow by:

- Standardizing print settings

- Creating design checklists

- Printing similar jobs together

- Training staff properly

For example, printing light-color designs together reduces ink switching and cleaning cycles.

Even saving 2–3 minutes per job adds up to hours over a week.

Supplier Negotiation and Bulk Purchasing

Buying small quantities increases per-unit cost.

If your daily usage is stable, bulk buying helps.

Smart purchasing tips:

- Buy PET film in rolls instead of sheets

- Order ink monthly instead of weekly

- Negotiate repeat order discounts

Using consistent supplies like Hot Melt Adhesive Powder from DTFshop.in ensures predictable results and fewer trial prints.

Good suppliers value long-term buyers. Even small discounts help over time.

Energy and Labor Cost Reduction

Electricity bills can quietly drain profits in DTF Printing.

Reduce energy costs:

- Turn off heaters when idle

- Avoid overheating curing units

- Print in batches instead of one-by-one

Labor costs can be controlled by reducing manual work.

If one operator can handle printing while another handles curing, productivity improves without extra hiring.

Clear roles reduce confusion and mistakes.

Automation and Software Tools

Automation is not just for big factories.

Even small shops benefit from:

- RIP software presets

- Automated white ink circulation

- Powder shaker systems

Automation reduces errors and speeds up production.

When machines do repetitive tasks consistently, humans can focus on quality control.

This leads to fewer rejected prints and better customer satisfaction.

Case Studies or Examples

A small DTF Printing shop in India reduced costs by nearly 20% by doing just three things:

- Switched to consistent ink and film

- Printed designs in grouped batches

- Followed a weekly maintenance checklist

Another shop reduced reprints by half after training staff on file checks before printing.

No new machines were added. Only habits changed.

Conclusion and Actionable Checklist

Reducing operational costs in DTF Printing does not mean cutting corners. It means working smarter.

Quick checklist you can start today:

- Track daily ink usage

- Clean print heads regularly

- Group similar print jobs

- Buy consumables in bulk

- Reduce idle machine time

- Train staff on common errors

Small changes, done daily, bring big savings over time.

DTF Printing is a long-term business. Cost control keeps it profitable.

Product Suggestions (Blue Color)

External References + Credits

Helpful industry resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply