1. How to Avoid Print Clogs and Issues in T-Shirt Printing – Pro Guide

What is Print Cogs and Issues in T-Shirt Printing and Why It Matters?

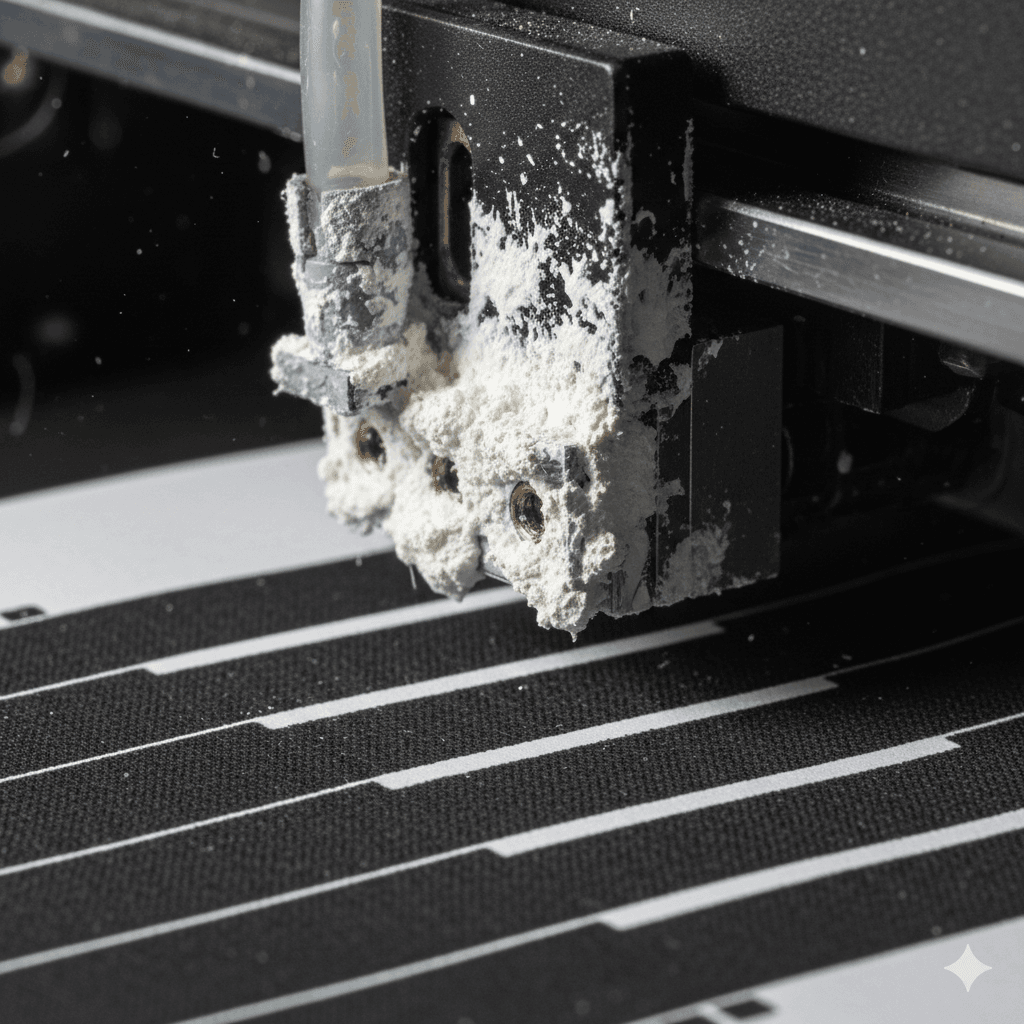

Anyone working in garment printing has experienced Print Clogs and Issues in T-Shirt Printing. One day the artwork looks sharp, and the next day the printhead starts spitting missing lines, uneven colors, or stops printing white ink completely. This problem affects delivery time, customer experience, and material costs. If not fixed quickly, printheads can get permanently blocked.

The truth is simple clogs are costly. You waste ink, waste film, and lose orders. Understanding why they happen and how to avoid them keeps your business running smoothly.

How It Works (Explained Simply)

A T-shirt printer pushes tiny droplets of ink through tiny nozzles. These nozzles are extremely thin — even smaller than a strand of hair. When ink becomes thick, dry, or gathers dust, the nozzles get blocked.

That’s how Print Clogs and Issues in T-Shirt Printing start.

Common reasons:

- White ink sedimentation

- Low-quality film sheets

- Poor humidity control

- Expired or cheap inks

- Dust or lint from fabric

- Not running the printer daily

Even the best printers face this if maintenance is ignored.

Benefits of Managing the Problem Early

Fixing clogs early gives multiple benefits:

- Better print quality every time

- Longer printhead lifespan

- Less ink wastage

- Faster production

- Happier customers

- Lower maintenance and repair cost

In short — prevention is cheaper than repair.

Focus Keyword Advantages

When you understand how to avoid Print Clogs and Issues in T-Shirt Printing, you unlock real advantages in your business:

- Smooth white underbase = better colors

- No banding on gradients and shadows

- Consistent print quality across batches

- Less reprints and fewer customer complaints

- Ability to handle large bulk orders without delays

This is the difference between an average print shop and a reliable one.

Related Machines You Can Use

To reduce Print Clogs and Issues in T-Shirt Printing, choose machines designed for smooth ink flow and automatic maintenance.

Recommended products from DTFshop.in:

- 🔹 DTF PRO Printer – All-in-One Model

- 🔹 DTF Mini Printer for Startups

- 🔹 DTF Premium White Ink (Non-Clog Formula)

- 🔹 Automatic Powder Shaker + Curing Machine

A machine that self-cleans and uses high-quality inks saves money in the long run.

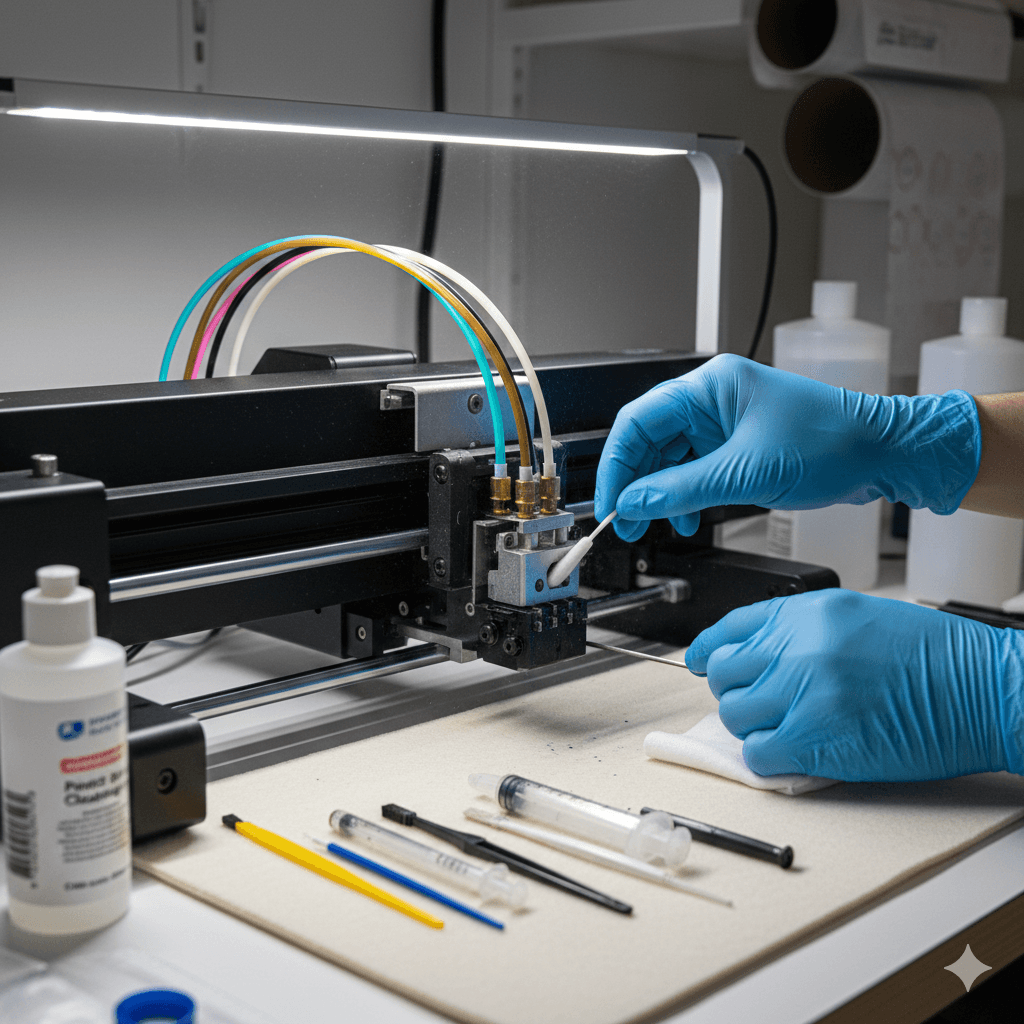

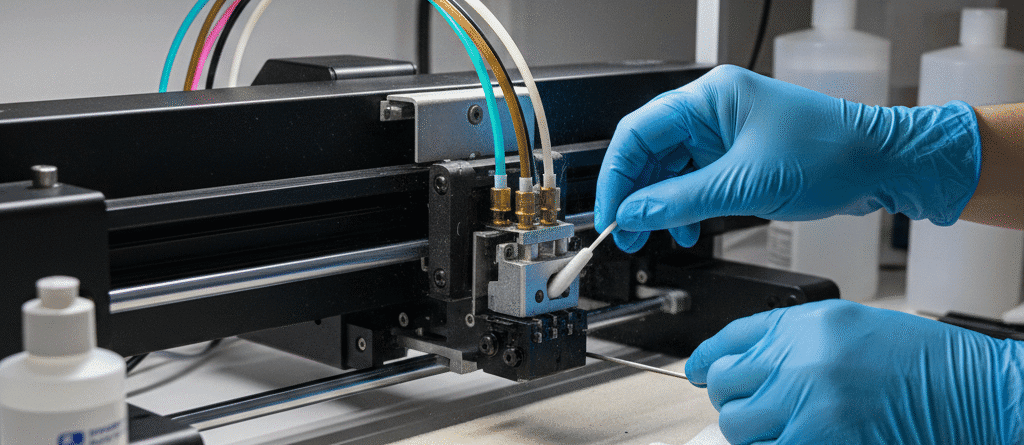

Step-by-Step Guide to Avoid Clog

Follow this simple checklist daily:

Daily

- Shake white ink bottles for 30–60 seconds

- Head cleaning (standard mode, not heavy)

- Print a 10×10 cm color + white nozzle test

- Keep capping station moist

Weekly

- Flush wiper blade and capping station with cleaning liquid

- Check film sheets for dust and store inside zip bag

- Clean printing area table to reduce fabric lint

Monthly

- Deep maintenance cleaning

- Replace ink filters

- Check humidity (Ideal: 45%–65%)

Pro Tips Learned from Real Shops

- Never keep white ink idle for more than 3 days

- Never power off the printer mid-cleaning cycle

- Use film before expiry date — old film absorbs moisture

- Keep the machine away from AC airflow

Just following these steps reduces Print Clogs and Issues in T-Shirt Printing by 80–90%.

Common Mistakes to Avoid

Beginners often repeat the same mistakes:

Running heavy cleaning every day → damages printhead

Mixing ink brands → chemical mismatch leads to clog Turning off printer for long holidays → ink dries inside Using cheap powder or film → ink does not settle correctly

Good materials save time and money. That is why professionals use:

External Expert References

For deeper scientific understanding of clogging and nozzle flow behavior, you can explore:

- PrintIndustry.com – ink drying and printhead behavior

- Fespa.com – garment printing guides and industry solutions

- InkJetInsights.com – printhead reports and ink chemistry

These sources helped the print community understand the real science behind clogging and prevention.

Frequently Asked Questions

1. Do clogs mean the printhead is damaged?

Not always. Early cleaning usually fixes it.

2. Why does white ink clog more?

Because it contains heavy pigments that settle faster.

3. Does climate matter?

Yes. Very dry rooms make ink evaporate faster inside the nozzles.

4. Which ink is best to reduce clogging?

Inks with anti-sedimentation formula — available on DTFshop.in.

Conclusion (Strong & Useful)

Every printing business faces Print Clogs and Issues in T-Shirt Printing, but smart shops prevent them rather than repair them. Maintain humidity, use good consumables, clean regularly, and never let ink stay idle for long. A little daily care protects your printhead and helps your business run smoother and faster.

Product Suggestions (Blue Color)

- 🔹 DTF PRO Printer – All-in-One Model

- 🔹 DTF Mini Printer for Startups

- 🔹 DTF Premium White Ink (Non-Clog Formula)

- 🔹 Automatic Powder Shaker + Curing Machine

- 🔹 High-Tack DTF Transfer Film (No Moisture Issues)

LEAVE A COMMENT