UVDTF Printing – The Ultimate Future Forecast for a Game-Changing Technology

Table of Contents

What is the Future of UVDTF Printing?

Introduction

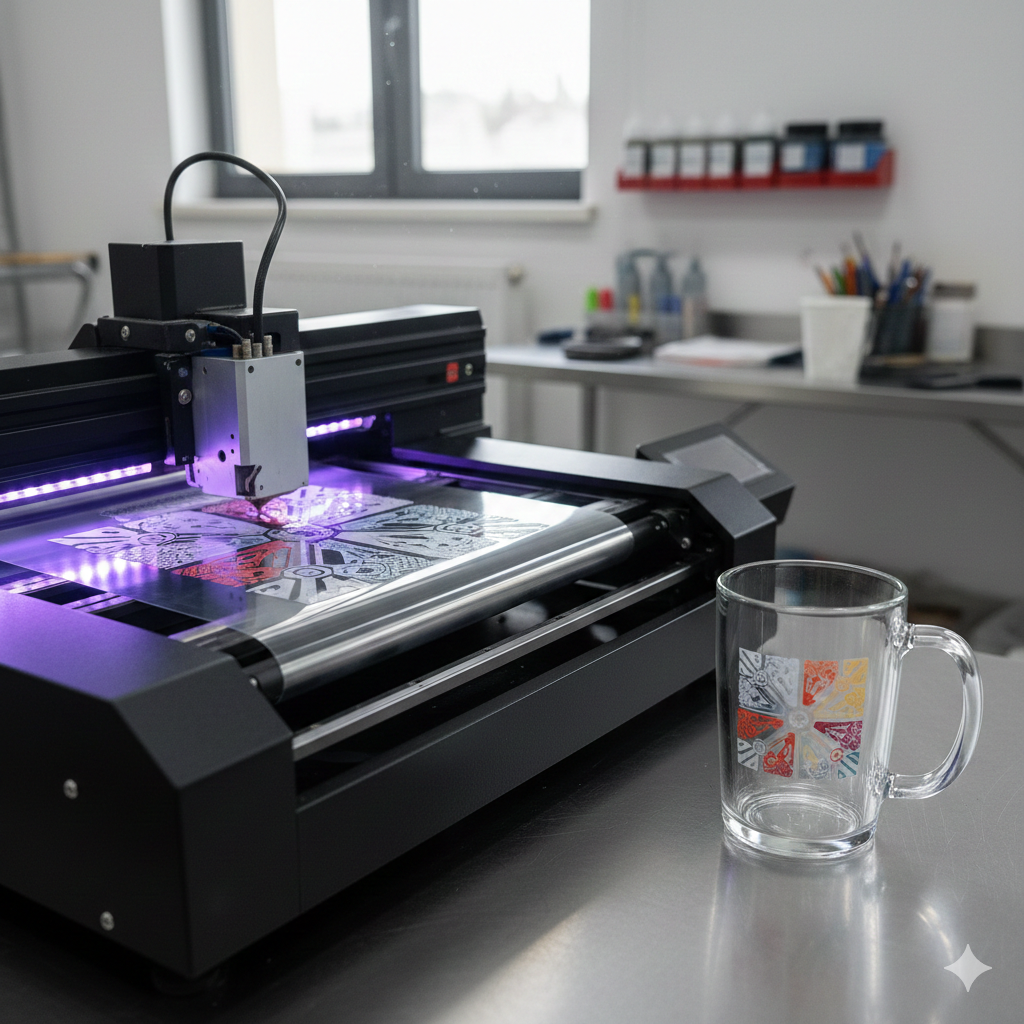

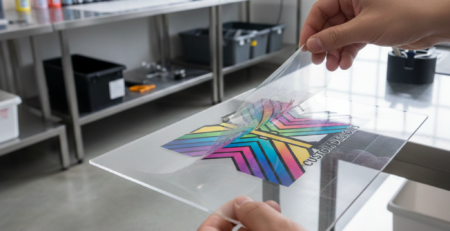

UVDTF Printing has quickly become one of the most talked-about technologies in the customization and print-on-demand industry. It combines UV printing with a direct-to-film transferring process, creating durable, glossy, and highly detailed prints. Businesses that used to rely only on sublimation or vinyl cutting now see UVDTF Printing as a way to decorate glass, plastic, metal, wood, ceramics, and many other surfaces without heat or pressure.

Due to its flexibility and premium finish, UVDTF Printing is shaping the future of personalized printing for brands, startup creators, and industrial manufacturers.

Current State and Advantages

Right now, UVDTF Printing is valued for three main reasons:

- Multi-surface compatibility – It works on curved surfaces like bottles and cups where traditional vinyl fails.

- Superior adhesion and durability – The UV-cured adhesive layer resists scratches, water, and sunlight.

- No professional equipment needed – Even small workshops can start using UVDTF Printing with compact printers.

Professionals like using machines similar to Aurora A3 UVDTF Printer, and the transfer films like A-B UVDTF Transfer Film Sheets available on DTFshop.in because they make printing reliable and repeatable.

Compared to sublimation, which requires polyester-coated items, or DTF which mainly focuses on textiles, UVDTF Printing gives more freedom in product choices from mobile cases to signage.

Emerging Technological Trends

The printing community has been watching key advancements that are pushing UVDTF Printing forward:

- Faster curing lamps for speed

- Better CMYK+W layering for strong opacity

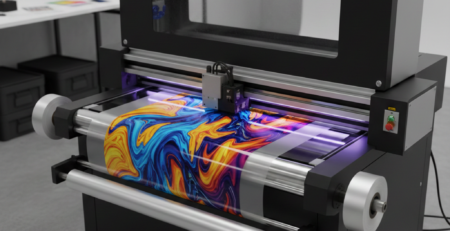

- Improved feeding systems to reduce film jamming

- Color management software for glossy and matte effects

Some professionals also pair UVDTF Printing with automation, using mini-rollers and automated laminating devices like UVDTF Automatic Powdering & Laminating System from DTFshop.in to handle bulk orders.

Reports from industry analysis on Fespa.com show that demand for UV-based transfers is rising every quarter due to personalization markets.

Innovations in Inks and Materials

Ink scientists and researchers (as reported on ResearchGate) are working on:

- Deeper color saturation with less ink usage

- Eco-friendly resin-based adhesives

- Higher stretch resistance for curved surfaces

- Scratch-proof glossy finishing

New film coatings allow UVDTF Printing to stay intact on products exposed to heat or friction. Improved white inks maintain brightness even on dark surfaces.

A lot of studios now prefer durable inks available in UVDTF Premium CMYK+W UV Ink Set and UVDTF Glossy Lamination Varnish from DTFshop.in because they offer smooth finishing without bubbling.

Market Growth and Industry Applications

UVDTF Printing has created opportunities for both small creators and industrial manufacturers. The most common applications include:

| Product Type | UVDTF Advantage |

|---|---|

| Drinkware | Works on metal, glass & curved surfaces |

| Corporate Gifts | Premium glossy finish |

| Home Decor | Durable prints on wood and ceramic |

| Accessories | Smooth details on acrylic and leather |

| Branding Labels | Waterproof and tear-proof |

Based on articles from PrintIndustry.com, brands are increasing product customization to meet consumer demands, which is accelerating UVDTF Printing adoption.

Even wedding planners and event gift companies now expect small-batch unique products, opening doors for workshops using UVDTF Printing.

Challenges and Limitations

No technology is perfect. UVDTF Printing still has challenges:

- White ink clogging if machines aren’t cleaned regularly

- Adhesion issues on silicone-based products

- Production delays without proper laminating pressure

- Cost of inks can be slightly higher than standard DTF inks

However, most challenges relate to workflow, not the printing method itself. With routine maintenance and quality materials, almost all problems can be prevented.

Future Predictions and Opportunities

The most expected direction for UVDTF Printing includes:

🔹 Industrial-grade films allowing flexible/stretchable finishes

🔹 Fully automated film-feeding printers

🔹 AI-driven RIP software for optimal ink consumption

🔹 3D-texture and raised-print effects

🔹 Eco-friendly UV adhesive development

Growing industries like personalized gifts, signage, and premium packaging are investing in UVDTF Printing because of the long-lasting finish and low rejection rates.

We may even see vending-style “instant customization” booths in malls, where customers can print UVDTF labels on the spot.

If someone is planning to set up a long-term business, investing in a solid system like blue UVDTF A3 Pro Printer Bundle from DTFshop.in can make production smoother and scalable.

Conclusion and Recommendations

UVDTF Printing is no longer a trend—it’s becoming a core method of decoration across many industries. Its ability to stick to almost any surface means businesses don’t have to rely on multiple printing setups.

Success comes down to:

- Using good films and inks

- Keeping the printer clean

- Choosing the right RIP settings

- Testing samples before mass production

Professionals who adopt technology early often stay ahead in the printing market. UVDTF Printing offers that competitive edge.

External References + Credits

- Fespa.com — industry reports and market trends

- PrintIndustry.com — printing cost analysis

- InkJetInsights.com — technological innovations

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT