DTG Printing – Top 5 Powerful Facts Every Beginner Should Know

Table of Contents

Top 5 Questions About DTG Printing Answered

Introduction to DTG printing

DTG Printing has become one of the most popular methods for creating custom apparel. Whether someone is starting a clothing brand or printing a limited batch of T-shirts for an event, many people now choose DTG because of its clean quality and fast turnaround. Still, beginners have many doubts — about fabric choice, durability, and how the overall process works.

This article answers the top five questions about DTG printing in simple language. If you are thinking about investing in a printer or outsourcing your prints, this guide will help you understand the basics clearly.

Question 1: What is DTG printing?

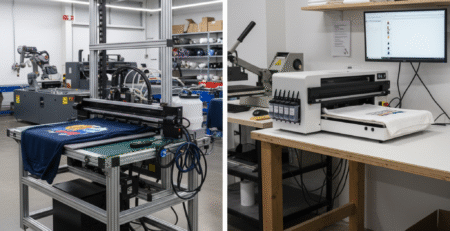

DTG Printing (Direct to Garment) is a method where a digital inkjet printer applies water-based pigment ink directly onto the fabric. Think of it like a regular home inkjet printer, but made for T-shirts. The design is printed precisely on the garment with high resolution including shadows, tiny text, and gradients.

Instead of screen meshes or vinyl cutting, DTG prints the image directly from the computer to the garment. This makes it perfect for:

- Short-run orders

- Multi-color artworks

- Photographic prints

For people working with customers who want fast and detailed prints, DTG printing can be a practical and cost-effective solution.

If you want to start printing, many beginners choose blank DTG-friendly T-shirts along with consumables like pretreatments and inks. A few useful product options from DTFshop.in include:

Question 2: What materials work best with DTG printing?

The best results for this come from 100% cotton garments. Cotton absorbs water-based ink naturally, giving bright colors and soft touch. Blended fabrics also work but the print may not look as sharp.

Approx. results based on fabric type:

| Fabric Type | Print Quality |

|---|---|

| 100% cotton | ⭐⭐⭐⭐⭐ Excellent |

| 80/20 cotton-poly | ⭐⭐⭐⭐ Good |

| 50/50 cotton-poly | ⭐⭐⭐ Medium |

| 100% polyester | ⭐ Low without special treatment |

Some professional print shops also use pre-treated cotton to improve sharpness and wash durability. For people planning small business printing, stocking the right blanks matters more than the printer itself.

Modern garment suppliers provide DTG-ready cotton T-shirts, sweatshirts and hoodies. DTFshop.in has some useful consumables for better fabric absorption like:

Question 3: How does the DTG printing process work?

Although this sounds technical, the workflow is quite simple once you try it a few times:

- Pretreat the garment

Dark garments especially need pretreatment so the white ink sits on top of the fabric instead of sinking inside. - Heat press for drying

Pressing helps the fabric become smooth and ready for ink. - Send design to the DTG printer

The print software reads the artwork and controls ink distribution. - Print directly on the fabric

The printer lays white underbase (for dark garments) and then prints color ink on top. - Final curing/heat pressing

This step bonds the pigment with the fabric fibers for good wash durability.

DTG printing does not require plates, screens or stencils so even single-piece orders are cost-effective. Technical explanations of ink bonding are well documented on InkJetInsights.com, which show how the micropigment particles attach to fabric fibers when heat cured.

Question 4: What are the advantages of DTG over other printing methods?

Compared to methods like screen printing and vinyl, DTG printing provides several practical advantages:

| Method | Strengths | Weaknesses |

|---|---|---|

| Screen printing | Very durable, best for bulk | Not ideal for detailed or full-color |

| Vinyl printing | Strong & shiny colors | Thick feel, limited gradients |

| DTG printing | Soft finish, prints photorealistic details, low setup cost | Works best on cotton only |

Most clothing startup founders prefer this when customers demand customized designs, names, character artwork, or short runs. Since the ink becomes part of the fabric, the printed area stays soft unlike vinyl which can feel heavy.

According to publications on PrintIndustry.com and Fespa.com, this continues to grow because it supports sustainability, low waste, and small-batch fashion brands.

Question 5: How to care for DTG printed garments?

Good care significantly improves the life of DTG printed T-shirts. Here are some useful care tips:

- Wash inside out — protects the print from friction

- Cold water wash — keeps colors intact longer

- Mild detergent — avoids print cracking

- Do not iron directly on print — iron from the back

- Avoid dryers if possible — air dry works best

With proper care, It can remain bright even after 40–60 washes. If customers receive printed garments with a slightly “flat” look in the first wash, don’t worry that is usually dried pretreatment residue, and it disappears after washing.

Conclusion and final thoughts on DTG printing

DTG printing has made custom apparel truly accessible. Beginners can start small, and experts can scale quickly without huge production costs. The method is clean, accurate, and flexible — especially for multi-color artwork and short-run orders.

Whether you are a print shop owner or a clothing business enthusiast, the more you experiment with fabrics, pretreatment amounts, and curing settings, the better your results will become. Testing is more important than equipment cost.

Call to action or encouragement to try DTG printing

If you want to explore DTG printing, start with basic materials and learn step-by-step. Small test runs will teach you more than reading manuals. Useful consumables like DTG Pre-Treatment Spray, Pigment Textile Inks, and Sample Print Packs from DTFshop.in can help you try prints on different garments before making big investments.

Leave a Reply