DTG Printing 2026 Power Guide: Common Problems and Fixes Explained

Table of Contents

Common Problems and Fixes for DTG Printing

Introduction

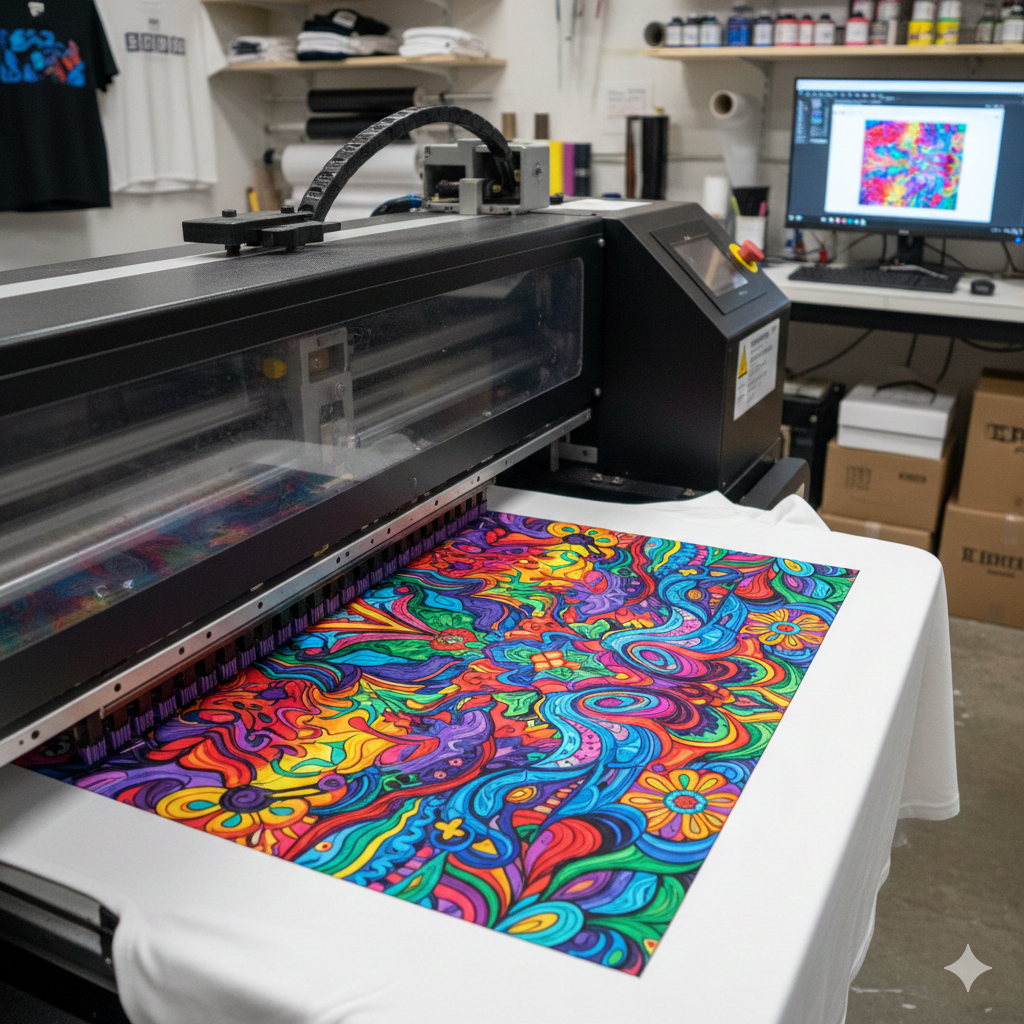

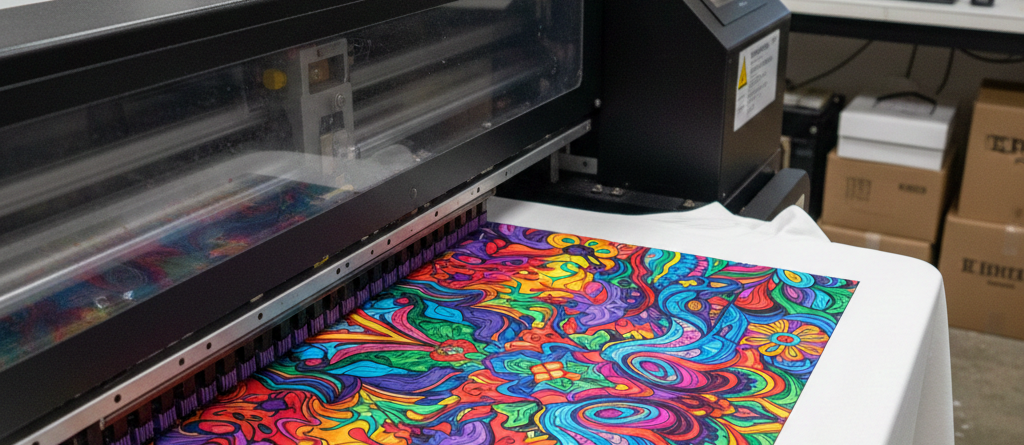

DTG Printing has changed the way custom garments are produced. It allows small batches, fast delivery, and full-color prints without screens. But anyone who has worked with DTG Printing knows it is not always smooth. Small mistakes can lead to wasted garments, poor prints, and lost time.

This guide explains the most common DTG Printing problems. You will learn why they happen, how to identify them early, and how to fix them properly. These are real shop-floor issues, not theory. The goal is to help you print better with fewer headaches.

Clogged Printheads

Causes

Clogged printheads are one of the most common DTG Printing problems. Ink dries inside nozzles when the printer sits unused. Poor-quality ink and skipped maintenance also cause clogs. White ink is especially sensitive.

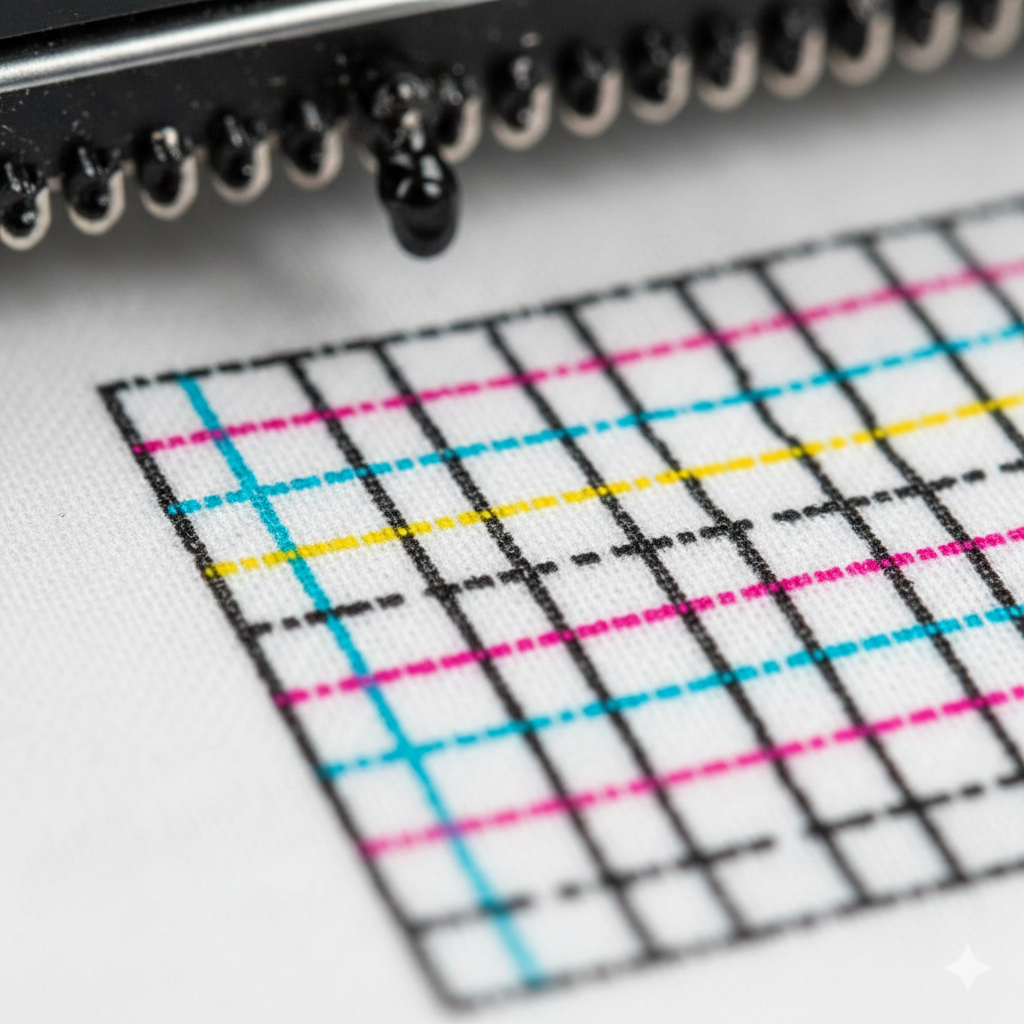

Identification

You will see missing lines, broken text, or patchy prints. Nozzle check patterns will show gaps. Colors may look uneven.

Fixes

Run a nozzle check daily. Perform light cleanings instead of heavy ones. Keep ink circulation on. If needed, use approved cleaning fluid. Store ink correctly and avoid cheap refills.

Many printers using DTG White Ink report fewer clog issues due to stable pigment quality.

Banding / Lines

Causes

Banding in DTG Printing usually comes from incorrect head height, low resolution settings, or mechanical vibration. Dirty encoder strips can also cause this issue.

Identification

You will notice horizontal or vertical lines across the print. These lines are evenly spaced and repeat across the design.

Fixes

Adjust platen height properly. Clean encoder strips gently. Increase print pass settings. Make sure the garment surface is flat and smooth.

Using a stable platen like DTG Adjustable Platen helps reduce movement during printing.

Faded Colors

Causes

Faded prints in DTG Printing often result from poor pretreatment, low ink density, or incorrect color profiles. Washing garments too soon also causes fading.

Identification

Colors look dull or washed out. Blacks may appear gray. Prints lose vibrancy after one wash.

Fixes

Use correct pretreatment amounts. Cure prints properly. Check ICC profiles in your RIP software. Always test wash samples.

Shops often pair quality ink with tools like DTG Pretreatment Liquid to maintain color strength.

Poor Adhesion

Causes

Poor adhesion happens when ink does not bond with fabric. This is common on dark garments when pretreatment is uneven or under-cured.

Identification

Ink cracks, peels, or flakes after washing. The print may feel powdery.

Fixes

Apply pretreatment evenly. Heat press at correct temperature and time. Avoid over-curing, which burns ink.

A consistent spray system such as DTG Pretreatment Spray Machine improves adhesion reliability.

Garment Shifting

Causes

Garment movement during DTG Printing causes blurred or double images. This happens when fabric is not secured or platen adhesive is weak.

Identification

Prints appear shadowed or misaligned. Edges look fuzzy.

Fixes

Use platen adhesive spray. Smooth garments before printing. Avoid stretching fabric. Choose correct platen size for each garment.

A strong hold spray like DTG Platen Adhesive Spray helps prevent movement.

Pretreatment Issues

Causes

Too much or too little pretreatment leads to problems. Incorrect drying also causes stains or box marks.

Identification

Dark stains, glossy patches, or visible spray lines appear on garments.

Fixes

Measure pretreatment correctly. Use heat press to dry evenly. Avoid hand spraying without proper tools.

Pretreatment problems drop significantly when using measured products like DTG Pretreatment Liquid with automated sprayers.

Software / RIP Errors

Causes

Wrong resolution, outdated firmware, or incorrect RIP settings cause DTG Printing failures. File transparency issues also play a role.

Identification

Colors print incorrectly. White ink floods or disappears. Designs shift or crop.

Fixes

Update RIP software regularly. Use proper ICC profiles. Flatten transparent layers. Test print before production.

Resources from InkJetInsights.com explain RIP calibration in detail.

Conclusion / Tips

DTG Printing is powerful but sensitive. Most problems come from skipped maintenance or rushed setups. Daily nozzle checks, clean platens, proper pretreatment, and correct curing solve 80% of issues.

Treat DTG Printing like precision work, not bulk printing. Small habits save big costs. Always test new garments and inks before full runs.

Product Suggestions (Blue Color)

DTG White Ink

DTG Adjustable Platen

DTG Pretreatment Liquid

DTG Pretreatment Spray Machine

External References + Credits

Helpful resources:

PrintIndustry.com

Fespa.com

InkJetInsights.com

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT