DTG Printing Mastery: Top 10 Mistakes Beginners Make in DTG Printing

Table of Contents

Introduction

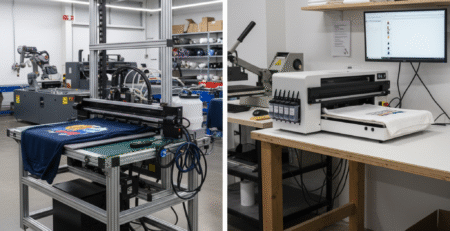

DTG Printing has changed the way custom t-shirts and garments are produced. It allows you to print full-color designs directly onto fabric with great detail. Many beginners enter DTG Printing thinking it is as simple as clicking “print.” In reality, it needs care, practice, and the right habits.

I have seen many new DTG users struggle with the same problems. Most of them are avoidable. These mistakes waste ink, damage machines, and reduce print quality. This guide breaks down the Top 10 mistakes beginners make in DTG Printing, explained in simple language with real examples and practical tips.

If you are new to DTG Printing or planning to invest in it, this article will save you time and money.

Mistake #1: Buying a DTG Printer Without Research

Many beginners buy the first DTG printer they see online. Price alone should never be the deciding factor. DTG Printing machines vary in ink system, maintenance needs, and fabric compatibility.

Some printers are good for small shops. Others are made for high-volume work. If you choose the wrong one, you may struggle with clogs, slow speed, or high ink costs.

Tip:

Compare printer size, ink type, support availability, and spare parts before buying.

Mistake #2: Ignoring Fabric Quality

DTG Printing works best on 100% cotton or high-cotton blends. Beginners often print on cheap fabric to save money. The result is dull colors, ink spread, and poor wash life.

Low-quality fabric absorbs ink unevenly. This makes even good designs look bad.

Tip:

Test fabrics before bulk printing. Use consistent GSM and weave.

A stable heat press also matters. Many beginners overlook this and end up with uneven curing. Using a reliable heat press like Heat Press Machine helps maintain consistent results.

Mistake #3: Skipping Proper Pretreatment

Pretreatment is not optional in DTG Printing. It helps white ink stick to fabric and keeps colors sharp. Beginners often under-apply or over-apply pretreatment.

Too little pretreatment causes ink bleeding. Too much causes stains and shiny patches.

Tip:

Use measured spraying and even coverage. Practice on scrap garments first.

A basic pretreatment sprayer or manual method is fine in the beginning, but consistency is key.

Mistake #4: Poor Artwork Preparation

DTG Printing shows every detail. Low-resolution images, wrong color profiles, or RGB/CMYK confusion can ruin prints.

Many beginners use images downloaded from the internet without checking size or quality.

Tip:

Use 300 DPI images. Keep transparent backgrounds clean. Convert colors correctly before printing.

Simple edits using professional software save ink and time.

Mistake #5: Not Maintaining the Printer Daily

DTG Printing machines need daily care. Skipping nozzle checks and cleaning cycles is a common beginner mistake.

White ink dries faster than CMYK ink. If left idle, it clogs print heads.

Tip:

Run daily nozzle checks. Shake white ink cartridges. Clean caps and wipers regularly.

Using proper inks and cleaning fluids is important. Products like DTG Cleaning Solution help keep the ink system healthy.

Mistake #6: Using Low-Quality Ink

Ink quality directly affects DTG Printing output. Cheap ink may look fine at first but fades after washing or damages the print head.

Many beginners switch ink brands without flushing the system properly, which causes chemical reactions inside the printer.

Tip:

Stick to recommended inks. If changing brands, flush the system fully.

For stable color output, users often prefer DTG Textile Ink designed for consistent flow and wash durability.

Mistake #7: Wrong Curing Time and Temperature

Curing is where DTG Printing either succeeds or fails. Beginners often under-cure prints to save time. This causes cracking and fading after washing.

Over-curing is also a problem. It burns fabric and dulls colors.

Tip:

Follow ink manufacturer curing guidelines. Use a thermometer to check heat press accuracy.

A dependable curing setup like Industrial Heat Press ensures even temperature across the platen.

Mistake #8: Ignoring White Ink Settings

White ink is the most challenging part of DTG Printing. Beginners often use default settings without testing.

Too much white ink makes prints thick and rough. Too little makes colors look weak.

Tip:

Adjust white ink layers based on fabric color and design.

Dark garments need strong white base. Light garments need minimal or no white.

Mistake #9: Not Calculating True Cost Per Print

Many beginners price jobs without knowing actual costs. DTG Printing includes ink, pretreatment, electricity, labor, and maintenance.

Without knowing cost per print, profits disappear quickly.

Tip:

Track ink usage and garment cost. Add maintenance and wastage into pricing.

This helps you price fairly and grow steadily.

Mistake #10: Expecting Instant Perfection

DTG Printing is a skill. Beginners expect perfect results from day one. When issues appear, they blame the machine.

Most problems come from setup, material choice, or process errors.

Tip:

Test often. Keep a print log. Learn from failed prints.

Even experienced DTG operators still test before large orders.

Conclusion

DTG Printing is powerful but not automatic. Beginners who rush the process face frustration and loss. By avoiding these common mistakes, you protect your investment and improve print quality.

Good fabric, proper pretreatment, correct curing, and daily maintenance make a big difference. Learn slowly. Print smart. Improve with every job.

DTG Printing rewards patience and consistency.

Call to Action

If you are starting with DTG Printing or upgrading your setup, focus on learning the basics first. Test materials. Maintain your machine. Choose reliable consumables. These small steps build long-term success.

Product Suggestions (from DTFshop.in)

External References + Credits

Helpful reading and technical insights:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply