DTF Printing – Ultimate Cost Breakdown for a Full Setup

Table of Contents

Introduction to DTF Printing Setup

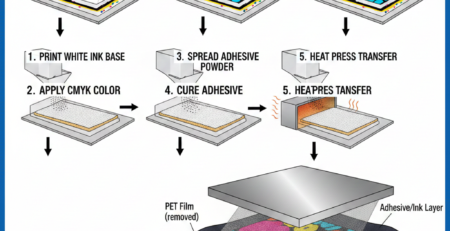

DTF Printing has become one of the fastest-growing apparel decoration technologies for startups and print shops. It works on fabric, leather, denim, canvas, blended garments, and even hard surfaces with excellent durability. The best part? A small workshop or room is enough to start.

But before investing, everyone wants the same answer:

How much does a complete DTF Printing setup cost?

This guide gives a transparent and practical breakdown so you know exactly what to expect — from machines to consumables to operational expenses.

Initial Equipment Costs

🖨 DTF Printer

This is the main investment. Prices vary depending on print size and speed.

- A4/A3 desktop DTF printers: Ideal for beginners

- 24-inch/60 cm production DTF printers: Suitable for commercial shops

While comparing, check printhead type, speed, color accuracy, and support availability.

Recommended options on DTFshop.in include:

A mid-level business commonly spends ₹1,50,000–₹4,50,000 for the printer alone.

🔥 Heat Press Machine

The heat press transfers the printed design onto garments.

Both clamshell and auto-open models work fine.

Good options available:

Powder Shaker/Dryer

This machine improves efficiency by applying powder evenly and curing it.

Ideal for shops printing more than 50 prints daily.

If budget is tight, manual powder application is possible but slower.

Curing Oven (Optional)

Many users skip this if they already have a heat press.

However, a curing oven increases production speed.

Air Filter/Ventilation

Models with built-in carbon filters reduce fumes. For small shops, a simple duct fan also works.

Consumables and Supplies Breakdown

DTF Inks

You’ll need CMYK + White.

High-quality inks ensure wash-resistant results.

Check on DTFshop.in:

🎞 Transfer Film

Comes in sheets or rolls.

Matte film gives better detail and prevents static.

🧂 Adhesive Powder

The powder decides stretchability and wash durability.

Hot-melt TPU powder is preferred.

🧽 Cleaning Solutions

Printheads need periodic maintenance to avoid clogging.

Never skip cleaning — it saves thousands in repairs.

Software and Accessories

💻 RIP Software/Licenses

RIP translates artwork into printable layers with correct color and white ink separation.

Annual licenses start around ₹12,000–₹35,000 depending on features.

🖥 Computers/Installation

A normal graphic system with 16 GB RAM and SSD is ideal.

Budget approx. ₹35,000–₹60,000 for a smooth workflow.

Operational and Recurring Costs

⚡ Electricity/Utilities

Even with heavy daily usage, electricity bills stay manageable due to efficient printers and heat presses.

🛠 Labor/Maintenance

Daily wiping and weekly deep cleaning prevent downtime.

Simplest rule: lower maintenance = higher print consistency.

Per-Print Cost Analysis

On average, for a standard 10×12 inch print:

| Component | Approx Cost |

|---|---|

| DTF inks | ₹9–₹13 |

| Transfer film | ₹8–₹12 |

| Adhesive powder | ₹5–₹8 |

| Electricity/labor | ₹3–₹6 |

| Total Cost | ₹25–₹39 per print |

Typical selling price per print in the Indian market: ₹120–₹200 depending on design and fabric.

Total Setup Budget Ranges

| Scale | Typical Spend |

|---|---|

| Budget beginner | ₹90,000 – ₹2,00,000 |

| Mid-level commercial | ₹2,50,000 – ₹4,50,000 |

| Professional production | ₹5,00,000 – ₹11,00,000 |

Budget vs. Professional Builds

Budget setups help people get started with DTF Printing but involve more manual work — manual powdering, slower curing, and lower volume.

Professional setups automate:

- Powdering

- Drying

- Curing

- Roll-to-roll printing

Higher investment = higher speed + lower labor cost per print.

Average Investment Summary

For someone planning a profitable and scalable home-to-studio business:

| Item | Ideal Budget |

|---|---|

| Printer | ₹2,00,000 – ₹3,50,000 |

| Powder shaker | ₹85,000 – ₹1,50,000 |

| Heat press | ₹25,000 – ₹55,000 |

| Initial consumables | ₹20,000 – ₹50,000 |

| Computer + software | ₹50,000 – ₹1,00,000 |

| Grand Total | ₹3,75,000 – ₹6,50,000 |

Cost-Saving Tips

- Buy rolls instead of film sheets — cheaper per print.

- Maintain printheads daily to avoid expensive repairs.

- Track ink usage — avoid over-white-layering.

- Print in batches to reduce curing time and electricity usage.

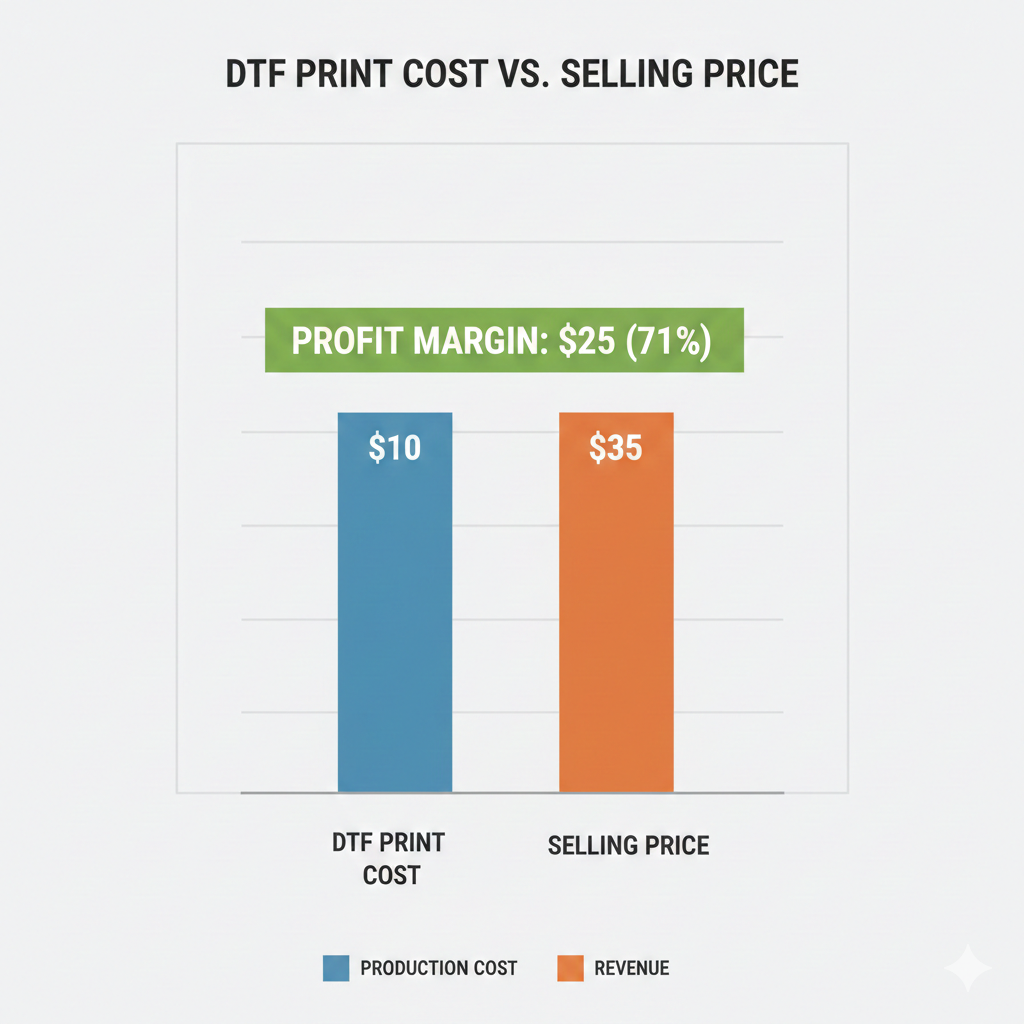

ROI and Profit Margins

If one shop prints 100 prints daily, profit estimate:

- Selling price (avg): ₹150 × 100 = ₹15,000

- Cost per print: ₹35 × 100 = ₹3,500

- Daily profit: ₹11,500

- Monthly profit (25 working days): ₹2,87,500

Most DTF Printing setups recover full investment within 2–4 months.

FAQs

Is DTF better than screen printing?

For short runs and multi-color designs, yes. For bulk single-color orders, screen printing is cheaper.

Does DTF work on dark garments?

Yes. White ink forms a base layer, allowing vivid prints even on black fabrics.

Is ventilation needed?

Highly recommended for long production hours.

Conclusion

Building a DTF Printing setup is one of the smartest investments for apparel entrepreneurs. Costs vary across budgets, but even small setups deliver high profit margins with low space requirements. Once workflows and maintenance routines are set, the business becomes predictable and scalable.

Product Suggestions from DTFshop.in (as used above)

- ProMax A3 DTF Printer

- Industrial 60 cm Dual Head DTF Printer

- Auto Open 16×20 Heat Press

- 30 cm Automatic Powder Shaker

- Premium White DTF Ink & CMYK Ink Set

External References + Credits

Information insights cross-verified from:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT