DTF Print 7 Essential Materials You Need for Perfect DTF Printing

Table of Contents

Introduction to DTF Printing

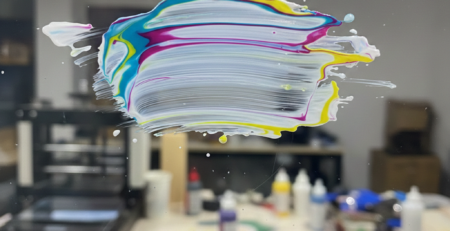

DTF Print, also known as Direct to Film printing, has changed the way custom garments are made. It allows printing designs on a special film and transferring them onto almost any fabric. Cotton, polyester, blends, light or dark colors all work well with DTF Print.

Small printing businesses prefer DTF Print because it does not need fabric pre-treatment like DTG. Setup cost is also lower compared to screen printing. But to get clean prints and long-lasting results, using the right materials is very important.

This guide explains all the materials needed for DTF Print, from basic equipment to consumables and optional tools. If you are starting or upgrading your setup, this article will help you avoid mistakes and save money.

Essential Equipment

DTF Printer

The heart of any DTF Print setup is the printer. A DTF printer is usually a modified inkjet printer designed to handle white ink.

A good printer should:

- Support CMYK + White inks

- Have smooth white ink circulation

- Work well with DTF RIP software

Many beginners start with reliable models available online like those found on DTF Printers, which are suitable for both home and commercial use.

Practical Tip:

Always shake white ink daily. This prevents clogging and keeps prints consistent.

Heat Press Machine

A heat press machine is used to transfer the design from film to fabric. Temperature and pressure control are critical in DTF Print.

Recommended features:

- Even heat distribution

- Digital temperature control

- Adjustable pressure

Flat heat presses work best for t-shirts and hoodies. You can explore reliable options under Heat Press Machines.

Key Consumables

DTF Film

DTF film is where your design gets printed before transfer. There are two common types:

- Cold Peel Film

- Hot Peel Film

Cold peel is more forgiving for beginners. It gives strong adhesion and better wash durability.

High-quality films from DTF Transfer Films help reduce powder waste and peeling issues.

Comparison Tip:

Cheap films save money upfront but often cause cracking after washes.

DTF Ink

DTF Print uses special pigment inks. These inks must bond well with adhesive powder and fabric.

Ink set includes:

- CMYK inks

- White ink

White ink quality directly affects color brightness. Poor ink results in dull prints and uneven coverage.

Professional-grade inks like DTF Inks offer better flow and longer printhead life.

Adhesive Powder

DTF adhesive powder sticks the ink to fabric during heat pressing.

Powder types:

- Fine (best for light fabrics)

- Medium (most commonly used)

- Coarse (heavy fabrics)

Medium powder is ideal for most DTF Print jobs. Consistent powder coverage avoids rough texture.

Check reliable powders available at DTF Adhesive Powder.

RIP Software

RIP software controls white ink layers and color profiles.

Common features:

- White ink base control

- Color management

- Print layout optimization

Many printers include RIP software bundled. Make sure your software supports your printer model.

Optional Accessories

Powder Shaker & Curing Oven

Manual powdering works for small setups. But for bulk production, automatic powder shakers save time and reduce errors.

A curing oven helps melt powder evenly before pressing. Some heat presses can do curing, but ovens give better consistency.

Cleaning Tools

Daily maintenance is crucial in DTF Print.

Keep these ready:

- Lint-free cloth

- Cleaning solution

- Capping station fluid

Neglecting cleaning is the main reason printers fail early.

Sourcing and Costs

DTF Print material costs depend on quality and volume.

Approximate starting costs:

- Printer: Medium investment

- Heat press: One-time cost

- Films & inks: Ongoing expense

Buying trusted supplies from platforms like Dtfshop.in ensures compatibility and fewer production issues.

Avoid mixing random brands. Ink and film chemistry must match.

Setup Tips

- Store white ink in cool conditions

- Keep humidity controlled

- Always test print before bulk runs

- Use correct heat press settings (usually 150–160°C for 10–15 seconds)

Real-life Example:

Many small shops face peeling issues only because they rushed curing. Extra 30 seconds of curing can save reprints.

Conclusion

DTF Print is simple once you understand the materials involved. The right printer, quality films, reliable inks, and proper heat press make a big difference in final output.

Do not chase the cheapest supplies. Focus on compatibility and consistency. With proper setup and care, DTF Print delivers professional results suitable for both small businesses and large production runs.

Product Suggestions (Internal Links)

External References + Credits

- PrintIndustry.com – Industry trends and equipment standards

- Fespa.com – Global textile printing insights

- InkJetInsights.com – Ink and printhead technology

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply