1. DTF Print Ultimate Guide: Complete Cost Breakdown for DTF Printing Setup

Table of Contents

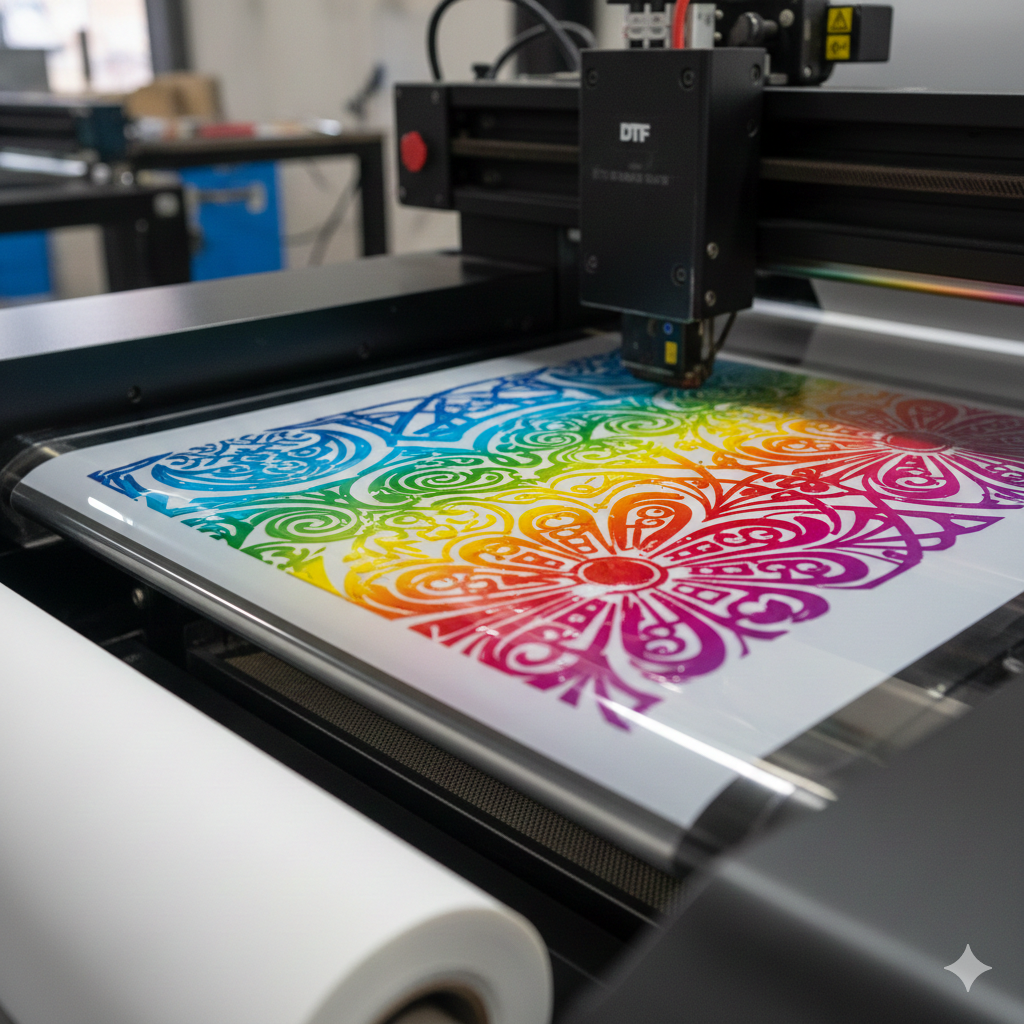

Introduction to DTF Printing Setup

DTF Print is growing fast in the custom apparel industry. Many small print shops, home businesses, and garment decorators are switching to it. The reason is simple. DTF Print works on cotton, polyester, blends, and even dark fabrics without complex pre-treatment.

But before starting, one big question comes up.

How much does a complete DTF Print setup really cost?

Some sellers show only printer prices. In reality, the total cost includes equipment, supplies, maintenance, and hidden expenses. This guide breaks everything down clearly. No hype. No sales talk. Just real numbers and practical experience.

If you are planning a This Print business or upgrading your shop, this article will help you budget correctly.

Essential Equipment List

To run a proper DTF Print setup, you need more than just a printer. Below is the basic equipment required.

Core Equipment

- DTF Printer

- Heat Press Machine

- Powder Shaker or Manual Powder Tray

- Curing Oven or Heat Tunnel

- Computer with RIP Software

Supporting Tools

- Humidity controller

- Cleaning kit

- Spare print heads

- Proper ventilation

Many beginners underestimate these items. Skipping them usually leads to print quality issues later.

Initial One-Time Costs Breakdown

This is where most of the investment goes in a DTF Print setup.

1. DTF Printer Cost

A good entry-level printer usually costs between ₹1,80,000 to ₹3,50,000 depending on size and brand.

A commonly used option is the DTF A3 Printer from DTFshop.in. It is suitable for small businesses and startup shops.

Larger A2 or A1 printers cost more but give higher production speed.

2. Heat Press Machine

A reliable heat press is critical. Cheap presses cause uneven pressure and peeling issues.

Estimated cost:

₹25,000 – ₹60,000

The 16×24 Heat Press Machine from DTFshop.in is commonly used for DTF Print transfers.

3. Powder Curing System

You can start manually using a tray and heat press. But production becomes slow.

Options:

- Manual powder tray: ₹3,000 – ₹5,000

- Automatic powder shaker & dryer: ₹1,20,000 – ₹2,50,000

The DTF Powder Shaker Machine helps save time for growing shops.

4. RIP Software License

Most DTF Print setups use EKPrint, Kothari, or Acrorip.

Estimated cost:

₹15,000 – ₹35,000 (one-time or yearly depending on version)

Ongoing Supplies and Consumables Costs

These are recurring expenses in DTF Print production.

DTF Inks

White ink is used heavily and costs more.

Monthly estimate:

₹6,000 – ₹12,000

The DTF White Ink from DTFshop.in is commonly used for stable white coverage.

DTF Films

Film quality affects peeling and wash durability.

Average cost:

₹12 – ₹20 per A3 sheet

Using poor film increases rejection rate.

Hot Melt Powder

Powder is cheap but essential.

Monthly usage:

₹1,500 – ₹3,000

The DTF Hot Melt Powder is suitable for cotton and poly blends.

Electricity

DTF Print uses more power than sublimation.

Monthly estimate:

₹2,000 – ₹4,000

Per-Print Cost Analysis

Let’s break down one A3 size DTF Print transfer.

Approximate cost per print:

- Ink: ₹18

- Film: ₹15

- Powder: ₹5

- Electricity & overhead: ₹5

Total per print cost: ₹43

Most shops sell one A3 DTF Print transfer between ₹120 – ₹200.

This leaves enough margin for profit, even after mistakes.

Total Setup Cost Summary Table

| Item | Estimated Cost (₹) |

|---|---|

| DTF Printer | 2,50,000 |

| Heat Press | 45,000 |

| Powder Shaker | 1,50,000 |

| RIP Software | 25,000 |

| Initial Ink & Supplies | 20,000 |

| Total Setup Cost | 4,90,000 |

You can reduce this to around ₹3,00,000 by starting manual and upgrading later.

Maintenance and Hidden Costs

Many beginners ignore maintenance in DTF Print.

Print Head Maintenance

White ink clogs easily.

Monthly cleaning cost:

₹1,000 – ₹2,000

Print head replacement:

₹25,000 – ₹45,000 (every 8–14 months depending on use)

Environmental Control

Humidity must stay between 45–60%.

Dehumidifier cost:

₹6,000 – ₹10,000

Skipping this leads to ink wastage and nozzle issues.

Profit Margins and ROI Tips

A small DTF Print shop producing 20 prints per day can generate:

Daily revenue:

₹2,400 – ₹4,000

Monthly revenue:

₹60,000 – ₹1,00,000

Most setups recover investment within 5–8 months.

Higher profit comes from:

- Bulk orders

- Logo prints

- White-label transfers for other printers

Cost-Saving Strategies

Here are real ways to reduce DTF Print expenses:

- Start with A3 size printer

- Use manual powder curing initially

- Buy ink in bulk

- Print daily to avoid ink settling

- Clean white ink lines every day

Avoid cheap films and powders. They cost more in reprints.

Conclusion and Next Steps

This Print is not cheap to start, but it is profitable when planned properly. A complete DTF Print setup costs more than just a printer. Supplies, maintenance, and power matter equally.

Start small. Focus on quality. Upgrade only when orders increase.

If you want steady income from custom printing, DTF Print remains one of the most flexible options today.

Product Suggestions (from DTFshop.in)

External References + Credits

Helpful resources:

- PrintIndustry.com – Industry trends

- Fespa.com – Printing technology insights

- InkJetInsights.com – Ink and print head research

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply