Vinyl Printing Best Comparison Guide vs Traditional Printing

Table of Contents

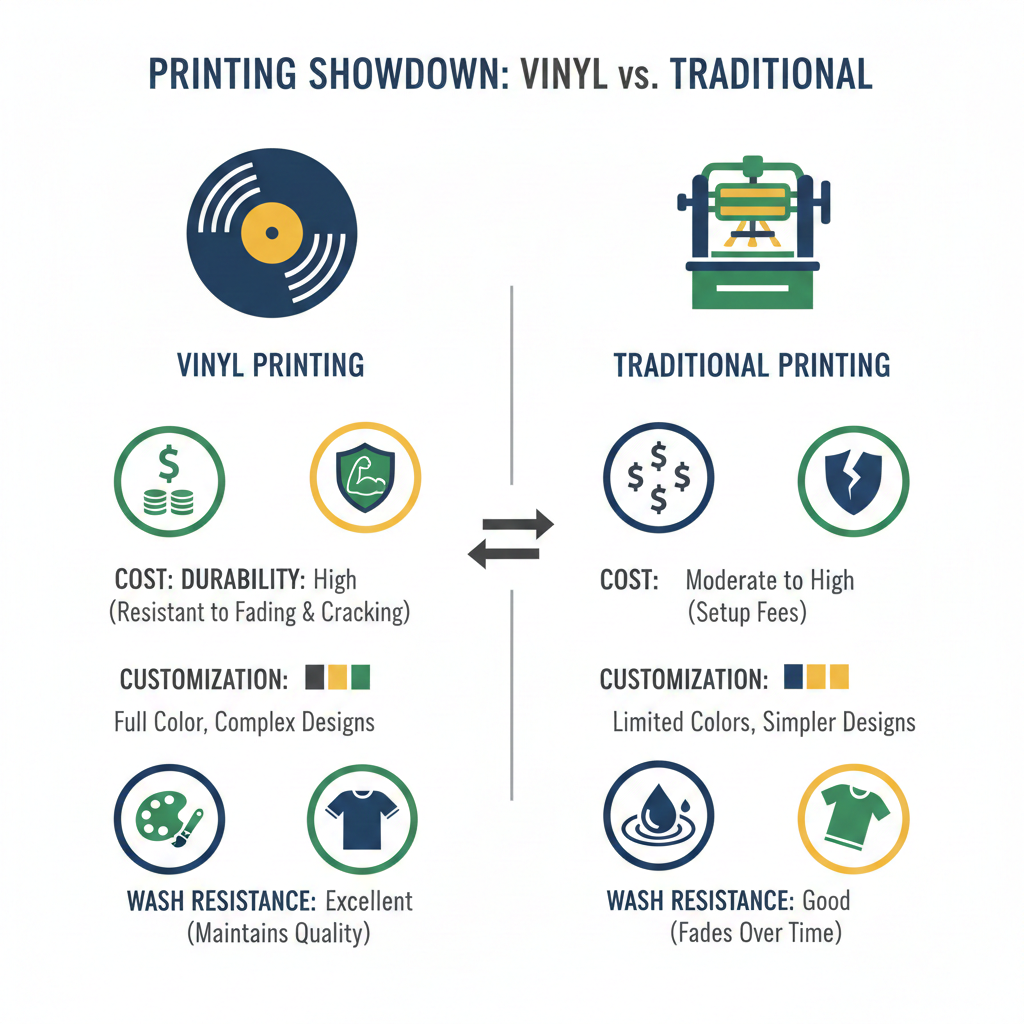

Comparison: Vinyl Printing vs Traditional Printing

Introduction

The printing world has changed a lot in the past decade. Businesses, designers, and even small home brands now want long-lasting and affordable prints for apparel, signage, bags, and promotional materials. Two techniques that are always compared are Vinyl Printing and Traditional Printing. Both deliver good results but in different ways. Choosing the right one can save time, money, and effort especially if you print for commercial purposes.

This guide explains the difference in simple language based on real usage and industrial practices.

What is Vinyl Printing?

It is a heat-based process where a colored vinyl sheet is cut into a specific design and then pressed onto the material using a heat press. The vinyl sticks on the surface and gives a raised, durable finish.

Common uses include:

- T-shirts and hoodies

- Sports jerseys with numbers and names

- Bags and caps

- Event merchandise and short-run prints

It is popular when customers want bold colors, metallic finish, glitter finish, or textured graphics. For example, a jersey number that stands out or a shiny logo on a black hoodie.

To start this Printing, many professionals use tools like a heat press and vinyl rolls. Some prefer ready-to-print transfers available at DTFshop.in, including products like PU Vinyl Rolls and Heat Press Machines.

What is Traditional Printing?

Traditional printing generally refers to older printing methods like screen printing, offset printing, and block printing. These methods apply ink directly to the surface.

Traditional printing is used mostly for:

- Bulk T-shirt production

- Posters and banners

- Paper packaging

- Corporate printing

It is great for high-volume production where single design setup runs into thousands of prints.

Key Differences

| Feature | Vinyl Printing | Traditional Printing |

|---|---|---|

| Print feel | Slightly raised | Flat ink |

| Minimum order | 1 piece | Usually 20–100 pieces |

| Durability | Very high | Medium to high |

| Best for | Text, logos, small batches | Large batch identical prints |

| Design detail | Very sharp | Good, depends on mesh/ink |

| Setup time | Low | High |

The biggest difference is flexibility. It works perfectly for customized and small-order apparel while traditional printing suits bulk orders.

Pros and Cons of Vinyl Printing

Pros

- Ideal for personalization (names, numbers, single prints)

- Highly durable and wash-resistant

- Works on cotton, polyester, nylon, and blends

- Many finish options like glitter, neon, and reflective

Cons

- Not suitable for very large detailed images or gradients

- Takes time for each piece because designs are cut individually

- Slightly thicker feel on the fabric

If you start a small business in apparel printing, Vinyl Printing is usually the easiest to learn. Many beginners use ready-to-apply designs from DTFshop.in, like Reflective Vinyl and Glitter Vinyl Sheets

Pros and Cons of Traditional Printing

Pros

- Very fast for 100+ quantity jobs

- Print quality is soft and lightweight

- Cost per piece decreases on bulk production

Cons

- Not economical for small orders

- Color or design change requires new setup

- Limited to flat surfaces for most methods

Traditional printing is the go-to method for mass production in the fashion industry.

Cost Comparison

| Order Type | Best Choice | Cost Range |

|---|---|---|

| 1–50 pieces | Vinyl Printing | Slightly higher per piece |

| 50–500 pieces | Traditional Printing | Lower per piece |

| Personalized Name/Number | Vinyl Printing | Cost-effective |

| Full-size photo print | Traditional Printing | More flexible |

If you print jerseys for sports teams, you will save more by printing team logos traditionally and adding player names through Vinyl Printing.

Applications and Use Cases

| Industry | Recommended Method |

|---|---|

| Sports jerseys | Vinyl Printing |

| Corporate uniform | Traditional |

| Customized gift items | Vinyl Printing |

| Event merchandise | Both |

| E-commerce clothing brand | Traditional |

| Small local printing shop | Vinyl Printing |

Many small printing businesses start with Vinyl Printing because the cost of setup is low and they can print on demand.

Quality and Durability

When done properly, Vinyl Printing can last more than 60–80 washes without fading. It resists cracking better than many low-budget traditional inks.

Traditional printing lasts long too, but depends heavily on:

- Ink brand

- Fabric quality

- Drying technology

- Whether curing temperature was correct

Sources like PrintIndustry.com and Fespa.com have detailed quality reports and wash-test information that give practical industry-based comparisons.

When to Choose Each Method

| Choose Vinyl Printing if… |

- You print low quantities

- You offer customization or names/numbers

- You want special finishes like glitter or reflective

| Choose Traditional Printing if… |

- You handle bulk orders

- You print flat-color artwork without personalization

- You want low cost for 100+ prints

In many print shops, both techniques are used together depending on the job requirement.

Conclusion

Both Vinyl Printing and traditional printing are excellent — the right choice depends on the order type and material. If you want personalization, flexibility, and high durability, Vinyl Printing gives great results even for small orders. For mass production, traditional printing is faster and more economical.

This comparison should help beginners, business owners, and print professionals make a smarter choice based on real-world practicality.

LEAVE A COMMENT