DTF Printing – Ultimate Guide to Avoid Print Clogs & Issues

Table of Contents

How to Avoid Print Clogs and Issues in DTF Printing

Introduction to DTF Printing

DTF Printing has become one of the most preferred methods for garment printing because of its durability, bright colors, and compatibility with almost any fabric. However, print clogs, film sticking problems, and powder inconsistencies can slow down production and frustrate beginners. The key is understanding how the DTF process works and how to prevent clogging before it happens.

What is DTF Printing?

DTF Printing (Direct-to-Film) is a method where the design is printed on a PET film and then transferred onto fabric using heat. Unlike DTG or screen printing, you don’t print directly on the fabric. This makes DTF flexible for polyester, cotton, denim, nylon, and more.

How DTF Printing Works (Step-by-Step Process)

1. Design Preparation

Use high-resolution artwork and proper color profiles. Sharp edges and clean backgrounds reduce ink usage and lower the chances of printer clogging.

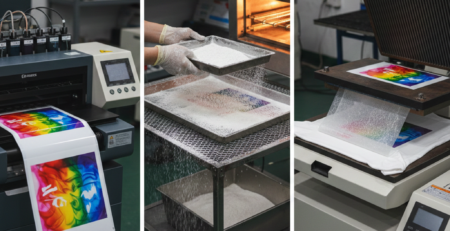

2. Printing on Film

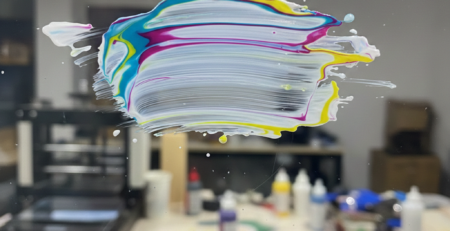

The printer layers CMYK ink first and white ink later. If white ink is too thick, the nozzles clog easily. A clean environment and regular printer head maintenance make a big difference.

3. Applying Powder / Adhesive

Shake powder evenly. Too much powder causes rough texture, too little weakens adhesion.

Using high-quality powder keeps prints soft and durable.

4. Curing the Film

Cure until the surface turns glossy—not burning. Curing too fast causes bubbles, while curing too slow traps moisture.

5. Heat Transfer to Fabric

Press at the required temperature and pressure based on the film type. Every fabric reacts differently, so test before bulk printing.

Equipment and Materials Needed

To run smooth DTF Printing, reliable materials are important, not just the printer. Many beginners use random inks or powders and face clogging every few days.

These products from DTFshop.in are known for consistent performance:

🔹DTF Printhead Cleaning Solution

Using stable supplies reduces nozzle clogging, peeling prints, and wasted films.

DTF vs. Other Methods (DTG, Screen Printing)

| Feature | DTF Printing | DTG | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | Almost all fabrics | Mostly cotton | All, but depends on technique |

| Cost on small orders | Low | High | High |

| Feel on Fabric | Soft | Very soft | Slightly thick |

| Prep Time | Low | Low | High |

| Best for | Mixed fabrics, small runs | Cotton T-shirts | Bulk orders |

DTF Printing wins when you need flexibility, low startup cost, and sharp detailing.

Pros and Cons

Pros

- Works on most fabrics

- Long-lasting prints

- Crisp design details

- Great for business startups

Cons

- Nozzle clogging if white ink is stagnant

- Powder smell if not ventilated

- Film storage sensitive to moisture

Design Tips for DTF

- Use larger fonts for better clarity

- Avoid tiny white outlines on small letters

- Add stroke to thin shapes to prevent cracking

- Avoid unnecessary gradients on small logos

A simple design prints better than an over-styled one.

Common Mistakes and Troubleshooting

| Mistake | Result | Fix |

|---|---|---|

| White ink not shaken | Clogging | Shake daily |

| Low-quality powder | Peeling | Use premium powder |

| Film stored in humid area | Smudges | Keep film sealed |

| High curing temperature | Bubbles | Reduce 5–10°C |

| Thick white layer | Rough print | Reduce white ink density |

A practical tip from many print shops: run a nozzle check every morning, even on low workloads. This keeps white ink circulating and prevents dried-up heads.

If printhead is partially clogged, use Blue — DTF Printhead Cleaning Solution instead of aggressive cleaning cycles that waste ink.

Business Setup and Costs

Starting a small DTF Printing setup is cheaper compared to DTG or screen printing.

| Item | Approx Cost |

|---|---|

| DTF Printer | ₹80,000 – ₹2,50,000 |

| PET Film | ₹3,000 – ₹6,000 per roll |

| Ink | ₹3,500 – ₹7,000 per liter |

| Heat Press | ₹10,000 – ₹40,000 |

| Workspace | 100 – 150 sq ft |

Even a home setup can generate stable earnings by printing for local clothing brands, schools, corporates, and custom gift shops.

Conclusion

DTF Printing is reliable and scalable if maintained properly. Most print clogs happen due to white ink sedimentation, moisture, and using inconsistent consumables. With the right workflow and good materials, you can run long production cycles with minimal downtime and excellent print quality.

External References + Credits

To maintain long-term print quality in DTF Printing, it helps to learn from reliable industry sources. For deeper technical reading about fabric durability and ink curing temperatures, PrintIndustry offers detailed guides at:

https://www.printindustry.com

You can also explore the latest textile printing innovations and maintenance tips at FESPA:

https://www.fespa.com

For highly technical ink performance insights, case studies from InkJet Insights are useful:

https://www.inkjetinsights.com

Some research teams have studied the bonding strength of hot melt adhesives in the transfer printing industry. A research abstract can be found here:

https://www.researchgate.net

LEAVE A COMMENT