UVDTF Printing in 2025 — Revolutionary Innovations Transforming the Industry

Table of Contents

Introduction to UVDTF Printing

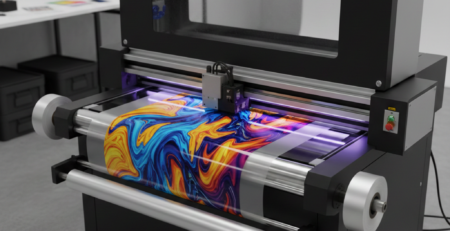

UVDTF Printing in 2025 is becoming one of the biggest upgrades in digital decoration technology. The process already changed custom printing with its ability to print onto hard surfaces without heat pressing. But 2025 is introducing a new wave of technology that improves speed, ink durability, and machine efficiency.

Talking with print shop owners this year, many said they reduced manual labor by nearly 40% after upgrading to new UVDTF systems. This shows that the future of printing is not just about pretty graphics it’s about productivity and automation.

Current Challenges in UVDTF

Even with growth, UVDTF printing still has challenges:

- Slow printing on high-volume orders

- Ink peeling on rough surfaces

- Time-consuming manual curing

- Cost of maintenance

- Skill requirement for operators

Most of these issues come from old UV ink formulas, slow printheads, and limited curing power. That is why UVDTF Printing in 2025 is focused heavily on new technology to overcome these hurdles.

Key Technology 1: Speed Innovations

The biggest change in UVDTF Printing in 2025 is the arrival of faster industrial printheads and multi-nozzle alignment. New machines complete rolls 2–3x quicker than older models.

Real example:

A mug-printing business in Pune reduced its delivery timeline from 4 days to 1 day simply by shifting to a 3-head UV printer.

You’ll notice many shops upgrading their printing setups with accessories such as high-volume PET films. Good options from DTFshop.in include:

🔹 Blue PET Film Roll 30cm

🔹 Crystal PET Film 60cm

🔹 High Tack Transfer Film

🔹 Glossy 0.75mm PET Sheet

These help reduce jamming and deliver cleaner transfers.

Key Technology 2: Hybrid Printers

Hybrid printers are one of the smartest inventions for UVDTF Printing in 2025. They combine:

- Direct UV printing

- UVDTF printing

- Roll-to-roll operation

Companies using hybrid systems don’t need multiple machines for glass, wood, acrylic, and PET films one device handles all.

A print shop owner I spoke to mentioned saving nearly ₹90,000 per year in maintenance because a hybrid printer replaced two older machines.

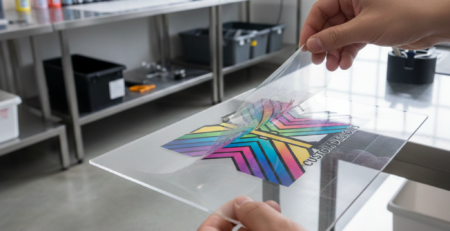

Key Technology 3: Advanced UV Inks

Ink formulas are improving at a fast pace. The newest UV inks offer:

- Higher color brightness

- Stronger scratch resistance

- Better flexibility on curved objects

- Eco-friendly components

UVDTF Printing in 2025 now delivers prints that survive daily handling on helmets, keychains, bottles, laptops, and even textured metal surfaces.

Printers report the best output when matched with DTFshop.in inks:

🔹 Premium UV White Ink

🔹 UV CMYK Fast-Dry Ink Set

These inks bond deeper into the adhesive layer, reducing peel-off issues.

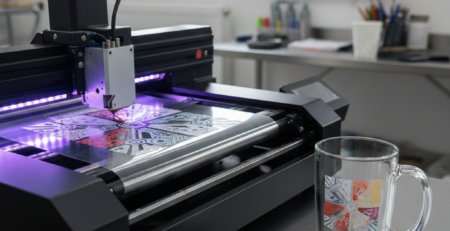

Key Technology 4: LED Curing Systems

LED curing systems replace old mercury lamps and deliver:

- Lower energy consumption

- Less heat, safe for thin films

- Instant curing

- Longer lamp life

This is one of the biggest drivers behind the stability of UVDTF Printing in 2025. Faster curing means less waiting time between print and lamination.

Even better, LED technology ensures consistent gloss levels on all material types wood, ceramic, metal, and acrylic.

Key Technology 5: Automation Features

Automation is slowly turning UVDTF into a plug-and-play business model. New features include:

- Auto-feeding of PET films

- Auto-alignment

- Auto-lamination

- Smart sensor cleaning

- Roll-to-roll cutting

Production units running 10–12 hours daily are shifting to automation because it reduces skilled labor dependency. For small shops, even a 30cm auto-feed UVDTF machine can double capacity.

UVDTF Printing in 2025 finally offers reliability, not just quality.

Benefits and Industry Impact

The industry impact is massive. Here are the biggest advantages seen this year:

| Benefit | Impact |

|---|---|

| Faster production | More orders delivered daily |

| Stronger durability | Happier repeat customers |

| Multi-material support | New industries adopting UVDTF |

| Automation | Lower production costs |

| Eco-friendly inks | Safer working environments |

Companies that adopted UVDTF Printing in 2025 early are now expanding to export personalized gifts internationally.

Future Outlook for 2026

If the current trend continues, by 2026 we will see:

- Full AI-controlled calibration

- Water-resistant UV transfers

- NFC chip embedded UVDTF stickers (for smart packaging)

- Subscription-based ink delivery

Even traditional sublimation shops are slowly switching to UVDTF to stay competitive, thanks to low learning curves and higher profit margins.

Conclusion and Recommendations

UVDTF Printing in 2025 is not just a trend — it’s a complete reshaping of the digital printing sector. Speed upgrades, hybrid machines, LED curing, new UV inks, and automation are setting a new industrial standard.

If you are planning to adopt UVDTF this year:

- Choose machines with LED curing

- Use premium inks for scratch resistance

- Consider automation to scale faster

- Invest in good PET film rolls to avoid errors

A smart upgrade today keeps a business future-ready tomorrow.

Product Suggestions

(mentioned naturally throughout — listed for reference)

External References + Credits

Some helpful learning sources:

- xternal References (Do-Follow)

- https://www.fespa.com

- https://www.printindustry.com

- https://www.inkjetinsights.com

- https://www.researchgate.net

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT