UVDTF Printing – Ultimate Reason Why Indian Printers Prefer It for T-Shirts

Table of Contents

Why Indian Printers Prefer UVDTF Printing for T-Shirts (must contain number)

Introduction to UVDTF Printing

The printing industry in India changes fast. Every year, printers look for better ways to produce stylish T-shirts without high cost or delays. In the past few years, UVDTF Printing has become the most talked-about solution. Small and large print businesses are using it because it works on cotton, polyester, blends, denim and even difficult fabrics. The results are sharp, glossy, long-lasting and require less effort.

Many Indian printers say it helped them take more orders during festive seasons and corporate gifting seasons when delivery timelines are tight.

Challenges Faced by Indian Printers

Before adapting UVDTF, printers struggled with:

- Long curing time in screen printing

- High wastage due to color mismatch

- Film cracking and fading after washing

- Heavy investment needed for DTG machines

- Customer demand for photo-quality T-shirt prints

- Heat press temperature issues for certain fabrics

Clients today want prints that survive rough washing and still look new. For many printers, keeping up with this demand was costly and stressful.

What is UVDTF Printing?

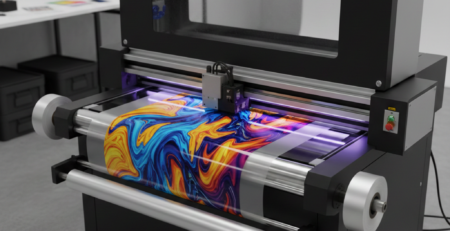

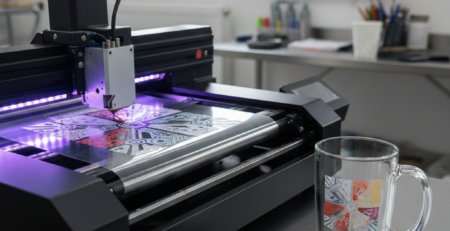

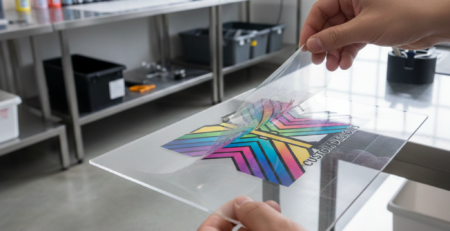

UVDTF Printing means Ultra-Violet Direct-to-Film printing. The design is printed on a special film using UV ink and hardened instantly using UV light. The printed film is then transferred to the T-shirt using pressure — not high heat.

Because of instant curing, the output looks embossed, glossy and premium. Many business owners say UVDTF gives the “sticker-like 3D effect” customers request.

UVDTF Printing also works on:

- Cotton

- Polyester

- Nylon

- Canvas

- Leather

- Denim

This flexibility is why Indian printers are quickly switching.

Key Advantages of UVDTF for T-Shirts

Indian print shops trust UVDTF Printing because it solves multiple problems in one setup:

| Advantage | Why It Matters in India |

|---|---|

| No pre-treatment | Saves time and chemicals |

| High durability | Survives rough washing |

| Works on any fabric | Best for mixed clothing orders |

| Glossy raised texture | Customers love premium finish |

| No color fading | Ideal for high-color artwork |

| Fast production | More revenue per day |

Because of these strengths, printers say UVDTF gives the confidence to take bulk orders without worrying about reprints.

Cost-Effectiveness in Indian Market

In India, profit margins matter. A new technique is successful only if it is affordable.

With UVDTF Printing, printers save in many areas:

- No need to buy expensive pre-treat liquid

- No need for large curing machines

- Low wastage rate

- Beginner-friendly for staff

A medium print shop can start UVDTF for far less investment compared to DTG or high-end sublimation setups.

Many printers use consumables from DTFshop.in because they are accessible and consistent. Good examples include:

🔹 UVDTF A3 Film Rolls – Highly durable and smooth for bulk production

🔹 UV Inks for Epson Printers – Vibrant colors for glossy finish

🔹 Heat & Cold Lamination Sheets for Textiles – Extra strong adhesive layer

🔹 Nozzle Cleaning Solution Kit – To maintain printheads easily

🔹 L1800 / XP600 Printhead Cartridges – Reliable for long printing hours

Comparison: UVDTF vs Traditional Methods

| Printing Type | Best For | Challenges |

|---|---|---|

| Screen Printing | Bulk logos | Long setup, not good for photos |

| Sublimation | Polyester garments | Limited fabric choices |

| DTG | Cotton + photo prints | High investment + slow printing |

| UVDTF Printing | All fabrics + glossy finish | Works best with UV printer |

UVDTF Printing combines speed, gloss effect and multi-fabric compatibility, something older methods cannot offer together.

Case Studies or Indian Printer Success Stories

Ahmedabad – Small Home Printer

A 2-person printing unit started offering UVDTF T-shirt designs for corporate orders. Within 3 months, demand increased, especially during Navratri festival. Customers wanted sparkling artwork and the glossy UVDTF finish helped them charge premium rates.

Bangalore – Established Print Shop

A traditional screen print company switched to UVDTF Printing for customized T-shirts. They reported 40% reduction in wastage and nearly double customer retention because prints survived frequent washing.

Kochi – College Merchandise Printer

The owner prints university hoodies using UVDTF. Students prefer the embossed look for club logos, and reorders continue every semester.

These stories show how the technique helps both small startups and large businesses.

Implementation Guide for Indian Printers

Printers planning to introduce UVDTF Printing can follow this simple roadmap:

- Start with a reliable UV printer

- Use compatible UV ink and good quality UVDTF film

- Keep room temperature stable for smooth film transfer

- Store prints in dust-free packaging

- Teach staff to apply constant pressure — not heat

Most print shops prefer consumables from DTFshop.in because the quality remains stable and it avoids printhead clogging.

A simple setup usually includes:

- UV Printer

- UVDTF Film Sheets or Rolls

- UV Curing Lamp (if not built-in)

- Transfer Tool / Scraper

Future Trends in UVDTF

Experts from Fespa.com, PrintIndustry.com and InkJetInsights.com predict that Indian garment exports will adopt UVDTF faster because:

- Demand for raised textures is increasing

- Corporate branding and event merchandise are growing rapidly

- Fashion houses like 3D logos on premium apparel

ResearchGate publications also show that UV ink chemistry is becoming more flexible for garment materials, which means the technology will only get better.

External References + Credits

- https://www.fespa.com

- https://www.printindustry.com

- https://www.inkjetinsights.com

- Research papers available on https://www.researchgate.net

Conclusion and Call to Action

UVDTF Printing has become the preferred choice for Indian T-shirt printers because it delivers premium results at affordable operational cost. It helps businesses take more orders, reduce reprints, and offer a glossy finish customers love.

If you are planning to enter the T-shirt customization business or expand your current setup, this technique is absolutely worth testing.

Leave a Reply