1. DTF Print Mastery: How to Avoid Ink Smudging in DTF Print

Table of Contents

Introduction

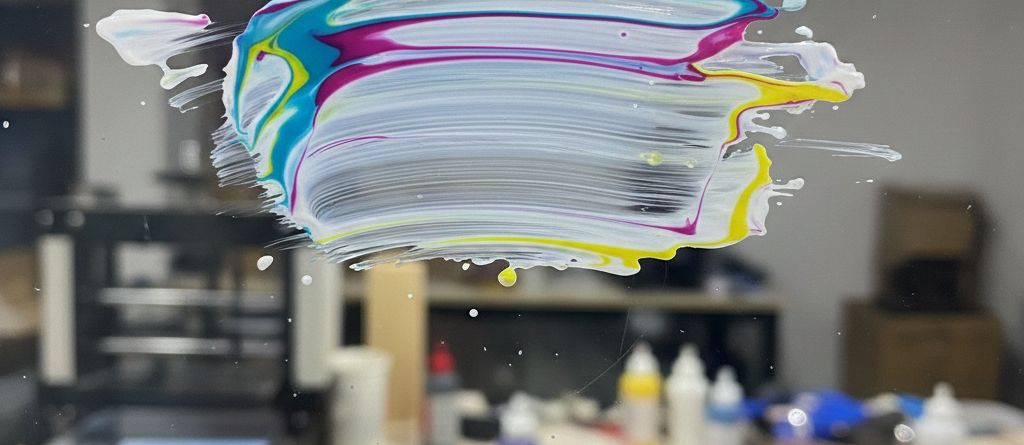

DTF Print ink smudging is one of the most common problems faced by beginners and even experienced printers. A design may look perfect on the screen, but once printed, the ink spreads, blurs, or transfers unevenly. This issue can ruin garments, waste ink, and slow down production.

Hook: Common DTF ink smudging issues

Ink smudging is one of the most frustrating problems in DTF Print.

You finish printing. The design looks sharp.

Then suddenly — ink spreads, edges blur, and colors mix.

Many beginners think this is an ink problem.

In reality, smudging is often caused by small process mistakes.

Thesis: Key prevention strategies

Avoiding smudging in DTF Print depends on correct preparation, printing control, curing, and handling.

Fixing just one step rarely works.

You need a complete workflow.

Overview of benefits

When smudging is controlled:

- Prints look sharp and professional

- Less reprinting and ink waste

- Better wash durability

- Faster production with fewer errors

Understanding Ink Smudging in DTF

Causes of smudging

In DTF Print, ink smudges mainly due to:

- Excess ink output

- Incorrect film type

- Low curing temperature

- Touching prints before curing

- High humidity

Unlike screen printing, DTF ink sits on film before transfer.

If not handled correctly, it spreads easily.

Impact on print quality

Smudging causes:

- Blurred edges

- Color bleeding

- Poor text clarity

- Rejected customer orders

Professional DTF Print shops lose money when smudging repeats.

Preparation Tips

Proper substrate selection

Not all PET films behave the same.

Cheap films absorb ink unevenly.

This increases ink spread.

Reliable films like DTF PET Film – Hot Peel provide controlled ink absorption and cleaner edges.

Surface cleaning techniques

Always clean:

- Film surface

- Printer platen

- Print area

Dust attracts ink moisture.

Even small particles cause smudging during DTF Print.

Ink and film compatibility

Using random ink brands causes chemical mismatch.

High-quality inks such as <span style=”color:blue”>DTF CMYK + White Ink Set</span> work best with recommended films.

Avoid mixing brands unless tested.

Printing Best Practices

Optimal printer settings

Over-inking is a major reason for DTF Print smudging.

Set:

- Lower ink density

- Balanced white ink layers

- Correct resolution (1440 DPI is enough)

More ink does NOT mean better quality.

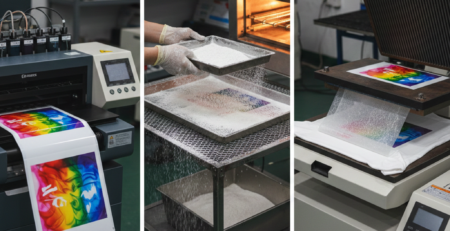

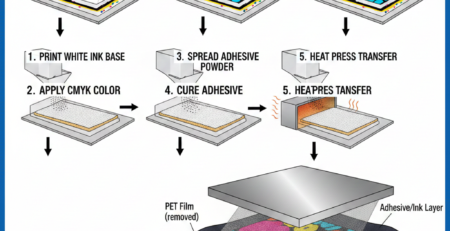

Ink curing methods

Partial curing leads to wet ink.

Use a curing oven or heat press hover method.

Consistent heat ensures ink stays in place.

A compact solution like DTF Curing Oven provides even heat distribution.

Layering sequence

Correct order matters:

- CMYK layer

- White ink layer

- Adhesive powder

Incorrect layering causes wet surfaces and smudges.

Application Techniques

Heat press temperature control

Too low temperature = ink movement

Too high temperature = ink bleeding

Ideal range for DTF Print:

- 150–165°C depending on film

Using a stable press like Automatic Heat Press Machine helps maintain consistency.

Pressure and time settings

Excess pressure pushes ink outward.

Use:

- Medium pressure

- 12–15 seconds press time

Do not rush.

Cooling process

Never peel while hot unless film allows it.

Let the print cool completely.

Hot peeling on wrong film causes smears.

Post-Print Handling

Storage conditions

Store prints:

- Flat

- Dry

- Away from sunlight

Humidity causes ink reactivation.

Handling protocols

Always hold film edges.

Never touch printed area.

Even dry-looking DTF Print can smudge under pressure.

Quality inspection checklist

Before pressing:

- No wet spots

- Clean edges

- Powder evenly melted

This step saves wasted garments.

Advanced Prevention Strategies

Equipment maintenance

Dirty print heads cause uneven ink flow.

Daily:

- Nozzle check

- Head cleaning

Weekly:

- Ink line inspection

Good maintenance improves DTF Print reliability.

Environmental controls

Ideal room conditions:

- Temperature: 20–25°C

- Humidity: Below 55%

High humidity is a silent smudging cause.

Software adjustments

Use RIP software to:

- Limit ink saturation

- Control white ink thickness

- Adjust choke settings

This prevents overloading the film.

Troubleshooting Common Issues

Quick fixes for smudges

- Increase curing time

- Reduce ink density

- Change film batch

- Improve airflow

When to reprint

Reprint if:

- Text edges bleed

- Colors mix

- Ink transfers before pressing

Never press a faulty DTF Print.

Conclusion

Key takeaways summary

To avoid smudging in DTF Print:

- Choose the right film and ink

- Control ink output

- Cure properly

- Handle prints carefully

- Maintain stable environment

Small improvements create big results.

Call to action: Try these tips

Apply these steps in your next DTF Print job.

You will see cleaner prints, fewer errors, and happier customers.

Product Suggestions (Used Naturally)

(All products available at DTFshop.in)

External References + Credits

Helpful reading sources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT