DTF Ink Powerful Guide: 7 Key Differences Between CMYK DTF Ink vs Pigment Ink

Table of Contents

Introduction

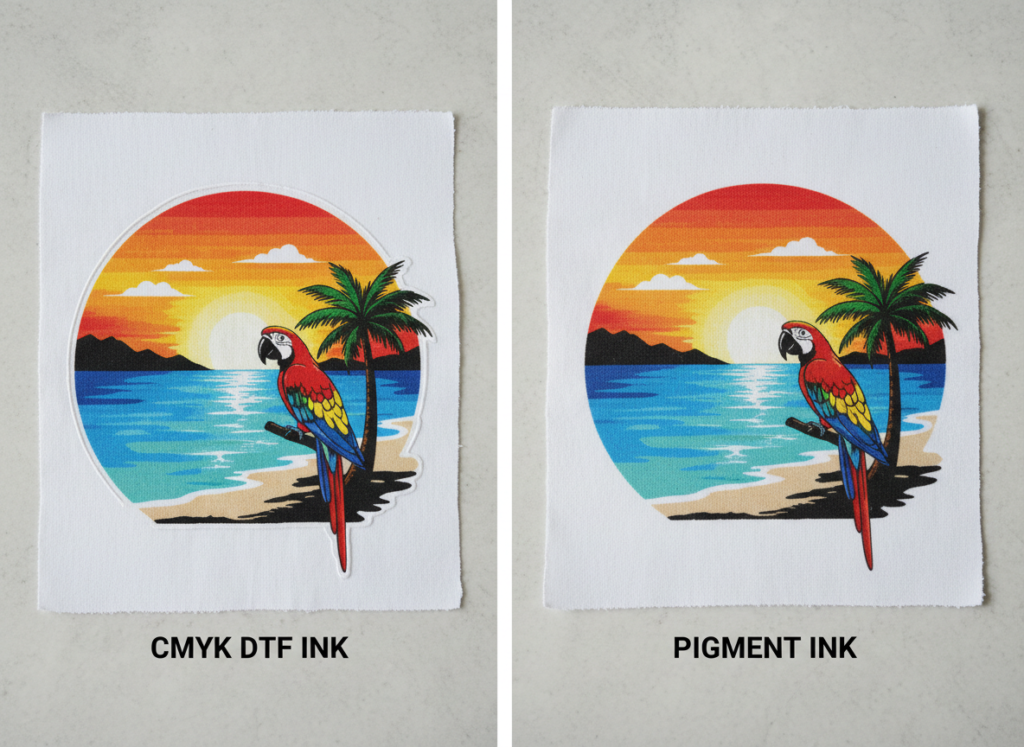

Choosing the right DTF Ink is one of the most important decisions in garment printing. Many printers struggle to understand the difference between CMYK DTF Ink and Pigment Ink. Both inks look similar at first, but they behave very differently on fabric, film, and during heat pressing.

If you run a DTF printing setup or plan to start one, this guide will help you clearly understand how DTF Ink works, where CMYK DTF Ink fits best, and when Pigment Ink makes sense. The goal is simple: fewer mistakes, better prints, and longer-lasting designs.

What is CMYK DTF Ink?

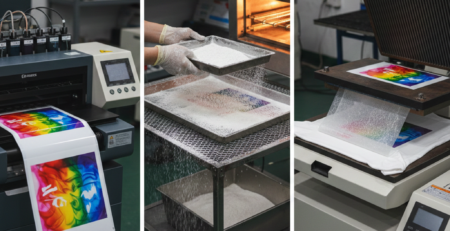

CMYK DTF Ink is specially formulated for Direct to Film printing. It uses four colors—Cyan, Magenta, Yellow, and Black—to create a wide range of shades. This Ink is designed to work with PET DTF films, adhesive powder, and heat press transfers.

Unlike normal inks, CMYK Ink has strong bonding properties. Once printed on film and heat-pressed onto fabric, it sticks firmly and remains flexible. This is why professional DTF printers rely on it for daily production.

CMYK Ink works best when paired with proper film and powder. Many users combine it with products like CMYK Ink Set – and DTF Transfer Film A3 to achieve consistent results.

What is Pigment Ink?

Pigment Ink is a water-based ink commonly used in desktop inkjet printers. It contains fine pigment particles suspended in liquid. Pigment Ink is popular for paper printing, posters, and basic fabric prints.

Some beginners try using Pigment Ink as a substitute for DTF Ink, but this often leads to poor adhesion and cracking. Pigment Ink lacks the elasticity needed for garments. While it can work for short-term or experimental prints, it is not made for real DTF transfer workflows.

Pigment Ink also reacts differently to heat. During heat pressing, colors may fade or shift. This is why Pigment Ink is not recommended for professional DTF printing.

Key Differences Between CMYK DTF Ink and Pigment Ink

| Feature | CMYK DTF Ink | Pigment Ink |

|---|---|---|

| Designed for DTF | Yes | No |

| Fabric Stretch | High flexibility | Low flexibility |

| Wash Durability | Excellent | Poor to average |

| Heat Press Compatibility | Perfect | Inconsistent |

| Color Accuracy | High | Medium |

| Professional Use | Recommended | Not recommended |

This table clearly shows why this Ink formulated for CMYK printing outperforms Pigment Ink in real garment use.

Applications and Use Cases

Where CMYK DTF Ink Works Best

- T-shirt printing

- Hoodies and sweatshirts

- Sportswear

- Cotton, polyester, and blended fabrics

- Light and dark garments

Most professional shops use CMYK Ink with tools like DTF Hot Melt Powder and DTF Heat Press Machine to ensure strong bonding.

Where Pigment Ink is Used

- Paper prints

- Art posters

- Sample testing

- Craft projects

Pigment Ink is not meant for full-scale garment production using this Ink workflows.

Pros and Cons

CMYK DTF Ink – Pros

- Made specifically for DTF printing

- Strong wash resistance

- Flexible on fabric

- Sharp and vibrant colors

- Professional finish

CMYK DTF Ink – Cons

- Slightly higher cost

- Requires correct settings

- Needs proper storage

Pigment Ink – Pros

- Easy to find

- Works on paper

- Lower cost

Pigment Ink – Cons

- Cracks on fabric

- Poor wash durability

- Not true DTF Ink

- Weak heat resistance

Practical Tips from Real Printing Experience

- Always shake CMYK Ink bottles before use.

- Keep white ink circulation on to avoid clogging.

- Use recommended curing temperatures.

- Never mix Pigment Ink with Ink systems.

- Clean print heads weekly for consistent output.

Many experienced printers rely on Ink Cleaner Solution to extend printer life and avoid blockages.

Conclusion

If you are serious about garment printing, CMYK Ink is the clear winner. Pigment Ink may look cheaper, but it creates more problems than savings in the long run. Proper Ink gives better color, flexibility, and durability.

For reliable output, always use inks, films, and powders designed specifically for DTF printing. This approach reduces waste, improves quality, and builds customer trust.

FAQs

Q1: Can Pigment Ink be used as DTF Ink?

No. Pigment Ink lacks flexibility and adhesion required for DTF printing.

Q2: How long does CMYK Ink last on fabric?

With proper curing, it can last over 50 washes.

Q3: Is CMYK Ink safe for all fabrics?

Yes, it works on cotton, polyester, and blends.

Q4: Does DTF Ink need special storage?

Yes. Store in a cool, dry place and shake regularly.

Product Suggestions (Blue Color)

- DTF CMYK Ink Set

- DTF Transfer Film A3/A4

- DTF Hot Melt Powder

- DTF Heat Press Machine

- DTF Ink Cleaning Solution

External References + Credits

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT