DTF Printing Ultimate Guide: 7 Powerful Truths About CMYK vs White Ink (Good & Bad)

Table of Contents

Introduction to DTF Printing

DTF Printing is one of the fastest-growing printing methods in the garment and customization industry. It is simple, flexible, and works on almost any fabric. Cotton, polyester, blends, light or dark colors DTF Printing handles all.

For beginners, the biggest confusion usually starts with inks. Especially CMYK and White Ink. Many people ask: Do I need both? How do they work together? Why does white ink matter so much?

This guide explains everything in plain language. No technical overload. Just practical knowledge based on real printing use. If you are starting DTF Printing or planning to upgrade your setup, this will help you avoid common mistakes and save money.

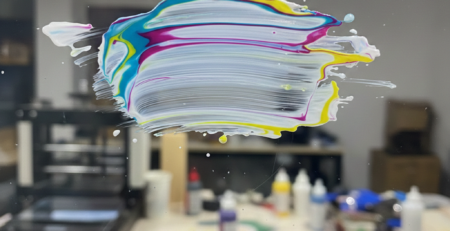

What is CMYK?

CMYK stands for Cyan, Magenta, Yellow, and Black. These are the basic color inks used in most digital printing systems.

In DTF Printing, CMYK inks create all visible colors in your design. Red, green, blue, skin tones everything is formed by mixing these four inks.

CMYK works best on light-colored fabrics. When printed alone, the fabric color shows through the ink. This is fine on white or pastel garments. But on dark fabrics, colors can look dull without support.

CMYK inks are thinner than white ink. They flow easily and usually cause fewer clogging issues. This makes them easier for beginners to manage.

What is White Ink?

White ink is the backbone of DTF Printing on dark fabrics. It acts like a base layer. Think of it as a white sheet placed under your colors.

When you print white ink first, CMYK colors sit on top of it. This makes colors pop, even on black or deep-colored garments.

White ink is thicker. It contains titanium dioxide, which gives it opacity. Because of this thickness, white ink needs more care. Regular shaking, circulation, and cleaning are very important.

Without white ink, DTF Printing would be limited mostly to light fabrics.

Key Differences: CMYK vs White Ink

CMYK inks are for color creation. White ink is for color support.

CMYK inks are transparent by nature. White ink is opaque.

CMYK is used in every DTF Printing job. White ink is optional but essential for dark fabrics.

CMYK requires normal maintenance. White ink needs daily attention.

Both inks work together. One is incomplete without the other in professional DTF Printing.

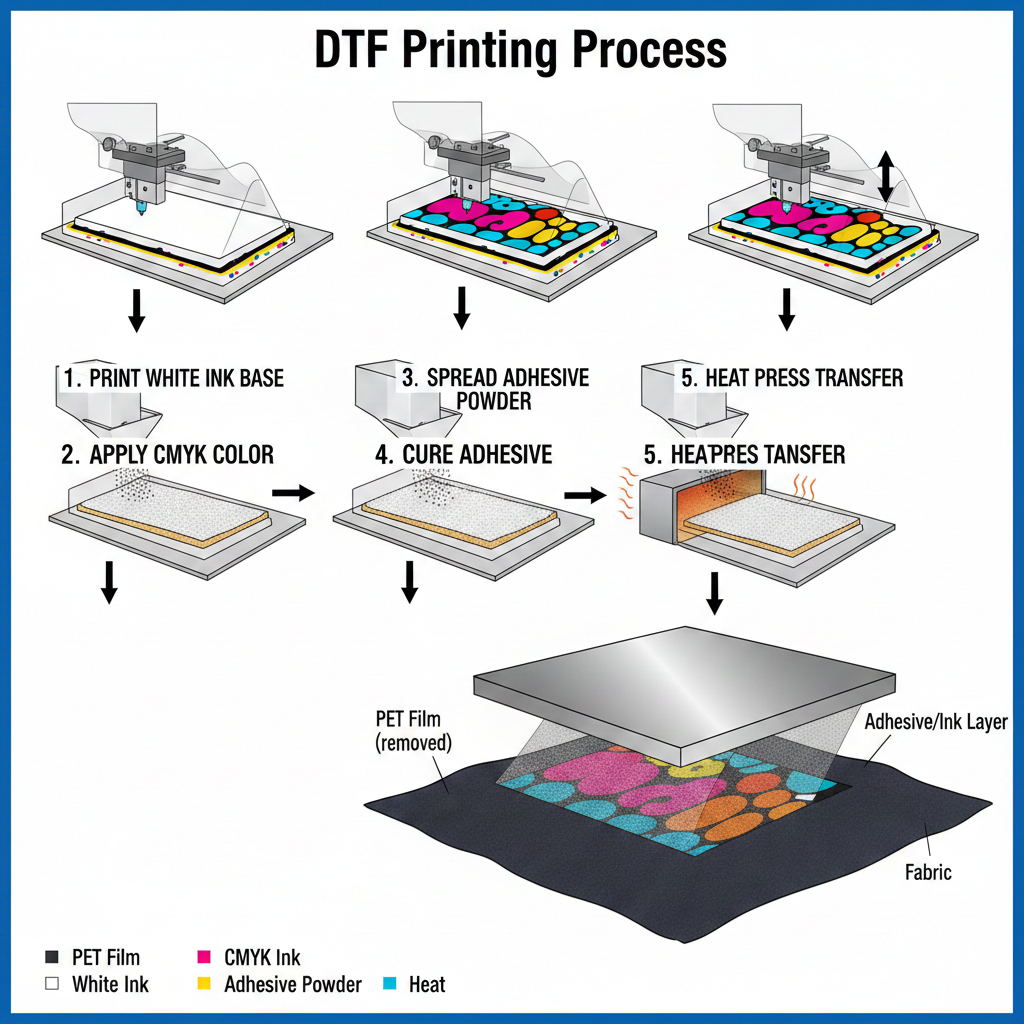

Printing Process with CMYK

In DTF Printing, CMYK inks are printed after the white layer or alone, depending on fabric color.

For light garments:

- CMYK prints directly on the film

- No white base is required

- The design stays soft and breathable

The RIP software controls color balance. Proper ICC profiles help achieve accurate shades.

CMYK layers are thinner. This allows faster drying and smoother transfers.

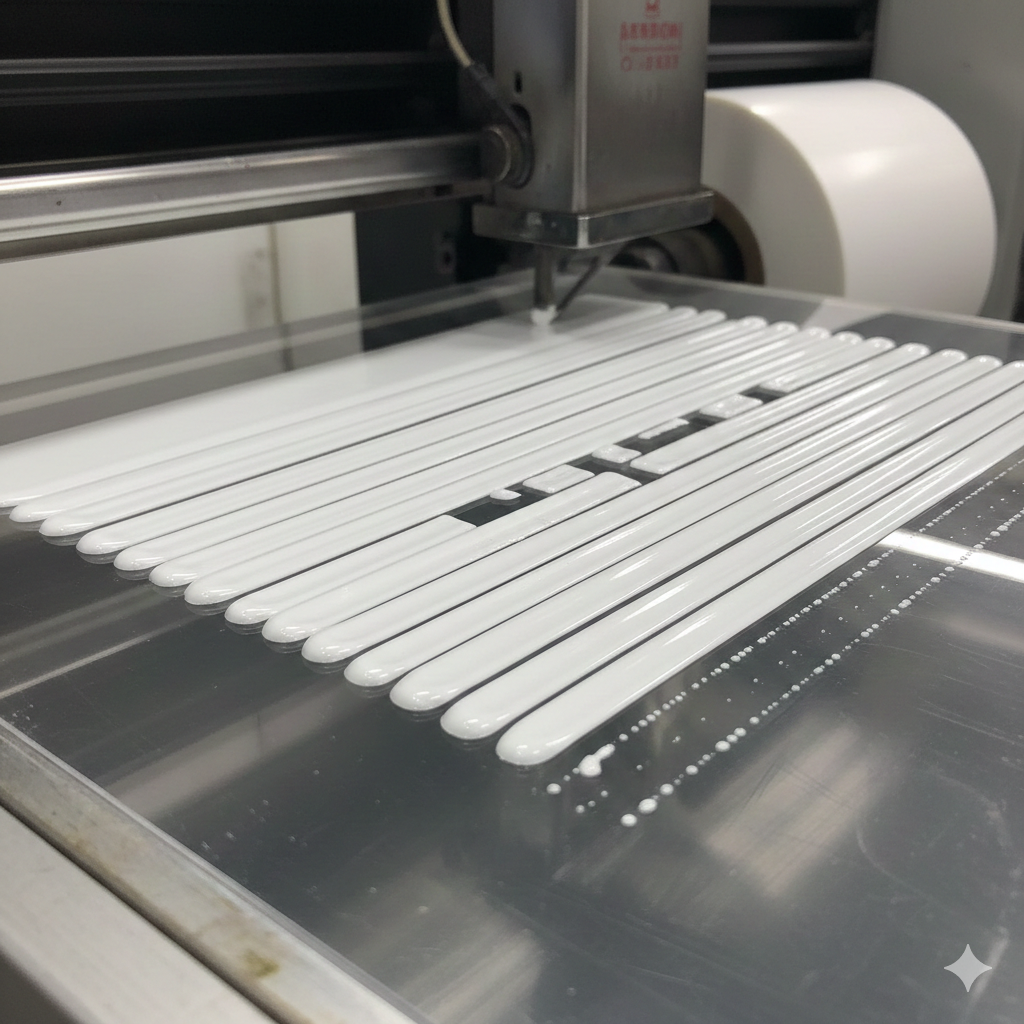

Printing Process with White Ink

For dark garments, white ink prints first.

Typical DTF Printing layer order:

- White ink base

- CMYK color layer

- Hot-melt adhesive powder

The white layer must be even. Too much white causes cracking. Too little makes colors dull.

White ink needs constant stirring. Many DTF printers include automatic white ink circulation systems. Beginners should never ignore this feature.

When to Use Each

Use only CMYK when:

- Printing on white or light fabrics

- Designs do not need high opacity

- You want a soft, lightweight print

Use CMYK + White Ink when:

- Printing on dark garments

- Printing bright colors

- Printing logos or images with fine detail

Most commercial DTF Printing jobs use both.

Pros and Cons Comparison

CMYK Pros

- Easy to maintain

- Smooth printing

- Less clogging risk

CMYK Cons

- Weak colors on dark fabrics

- Needs white ink support

White Ink Pros

- Strong opacity

- Bright colors on dark garments

- Professional finish

White Ink Cons

- High maintenance

- More cleaning required

- Slightly higher running cost

Beginner Tips and Settings

Start slow. Test small designs.

Always shake white ink bottles before use.

Clean white ink lines daily.

Use correct heat press temperature. Too much heat can burn white ink.

Store inks properly. Avoid direct sunlight.

Use good-quality films and powders. Cheap materials affect both CMYK and white ink performance.

Common Mistakes to Avoid

Ignoring white ink maintenance is the biggest mistake in DTF Printing.

Using too much white ink causes cracking after wash.

Skipping test prints wastes film and ink.

Wrong RIP settings can ruin colors.

Not curing adhesive powder properly leads to peeling.

Learning from mistakes is normal. Testing is part of DTF Printing success.

Conclusion and FAQs

DTF Printing becomes easy once you understand ink roles.

CMYK creates colors. White ink supports them.

Together, they allow printing on any fabric color.

Beginners should focus on maintenance, testing, and balance. With time, results improve naturally.

FAQs

Is white ink mandatory in DTF Printing?

No. But it is required for dark fabrics.

Does white ink increase cost?

Slightly. But it improves print quality greatly.

Can beginners handle white ink?

Yes, with regular cleaning and care.

Product Suggestions (blue color)

- DTF White Ink – Premium Grade

- DTF CMYK Ink Set – High Density Colors

- DTF PET Film – Hot Peel

- DTF Adhesive Powder – Medium Grain

- DTF Printer with White Ink Circulation

External References + Credits

Helpful reading sources:

- PrintIndustry.com – Digital printing fundamentals

- Fespa.com – Textile and DTF Printing trends

- InkJetInsights.com – Ink behavior and print technology

Credit: Information references from Fespa, PrintIndustry, and other public sources.

LEAVE A COMMENT