DTF Printing Power Guide: 9 Expert Tips to Choose the Best Heat Press

Table of Contents

Introduction to DTF Printing and Heat Press Role

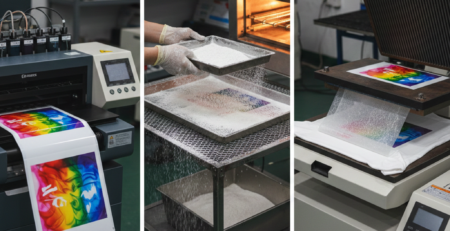

DTF Printing has become one of the most popular methods for custom garment decoration. It is flexible, cost-effective, and works on almost any fabric. But many people focus only on the printer and film, and forget one important machine — the heat press.

In DTF Printing, the heat press is not optional. It is the final step where the design actually bonds with the fabric. Even a perfect print can fail if the heat press is weak, unstable, or inconsistent.

A good heat press ensures:

- Proper melting of adhesive powder

- Even pressure on the entire design

- Long-lasting wash durability

In simple terms, your heat press decides whether your DTF Printing looks professional or cheap.

Types of Heat Presses (Clamshell, Swing-Away, Draw)

Understanding heat press types makes selection easier.

Clamshell Heat Press

This is the most common type used in DTF Printing.

Pros:

- Compact design

- Easy to operate

- Affordable

Cons:

- Pressure is stronger at the back

- Less space for thick garments

Best for beginners and small shops.

Swing-Away Heat Press

The upper platen swings away from the lower platen.

Pros:

- Even pressure distribution

- Safe and clear working area

- Excellent for DTF Printing quality

Cons:

- Needs more space

- Slightly higher cost

Ideal for professional DTF Printing setups.

Draw (Slide-Out) Heat Press

The lower platen slides forward.

Pros:

- Easy garment placement

- Reduces burn risk

- Good pressure control

Cons:

- Mechanical parts need maintenance

Often used in busy DTF Printing environments.

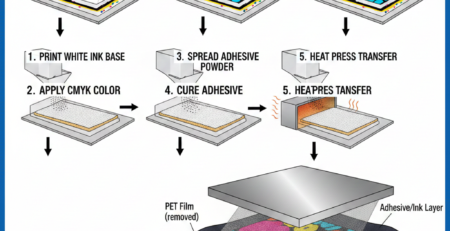

Key Features to Consider (Temperature Range, Pressure Control, Platen Size)

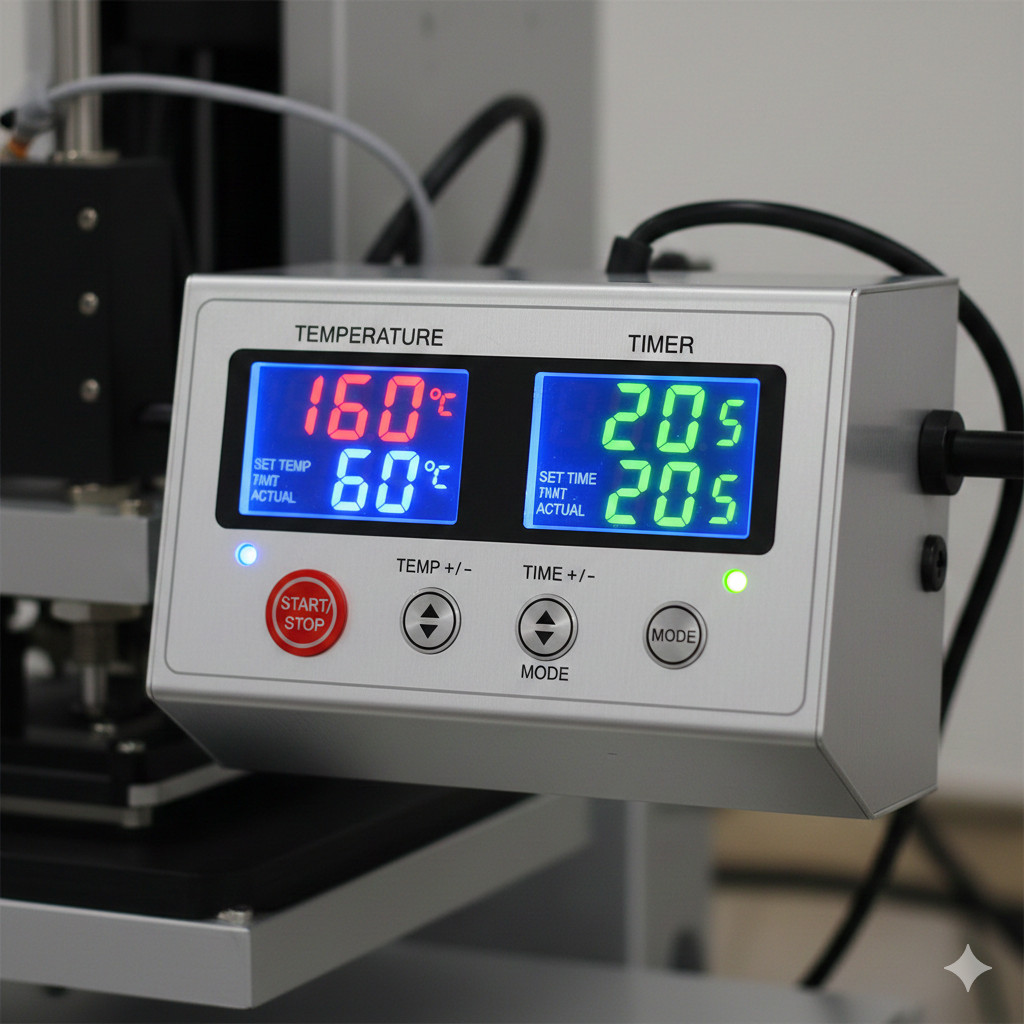

Temperature Range

DTF Printing typically needs 130°C to 160°C.

Your heat press must:

- Reach at least 180°C

- Maintain stable temperature

Cheap presses often show wrong readings. Always check reviews.

Pressure Control

Pressure is critical in DTF Printing.

Look for:

- Adjustable pressure knob

- Medium to firm pressure range

Too much pressure cracks designs. Too little causes peeling.

Platen Size

Common DTF Printing sizes:

- A4 designs → 15×15 inch

- A3 designs → 16×20 inch

Choose a platen that matches your film size. Bigger platens give flexibility.

Factors for Selection (Size Match, Stability, Adjustability)

Size Match

Your heat press should match:

- Film size

- Garment size

- Production volume

For logo printing, small platens work. For full chest designs, larger platens are better.

Stability

A stable heat press ensures even bonding in DTF Printing.

Check for:

- Heavy metal frame

- Non-wobbling handle

- Flat platen surface

Unstable presses ruin transfers over time.

Adjustability

Good presses allow:

- Pressure adjustment

- Temperature accuracy

- Timer control

DTF Printing requires fine tuning depending on fabric type.

Popular Models and Recommendations

For reliable results, here are some practical machine suggestions used by many small and medium businesses.

- DTF Pro Max Heat Press Machine

- DTF Heavy Duty Swing-Away Heat Press

- DTF Automatic Digital Heat Press

These machines are commonly paired with DTF Printers and films available at DTFshop.in. They are known for consistent temperature and long working life.

Budget and Space Considerations

Budget Planning

For DTF Printing:

- Entry-level heat press: ₹15,000 – ₹25,000

- Professional heat press: ₹30,000 – ₹60,000

Avoid ultra-cheap machines. They cause frequent design failures.

Space Requirement

Measure your workspace before buying.

Clamshell presses save space.

Swing-away presses need side clearance.

Good airflow and proper electrical connection matter in long DTF Printing sessions.

Maintenance and Usage Tips

Simple habits improve results.

- Clean platen weekly

- Avoid overheating beyond recommended levels

- Do test presses on scrap fabric

- Use silicone sheets when needed

Replace worn pads early. Uneven pads cause pressure issues.

Let the machine cool before switching off. This protects heating elements.

Conclusion with Final Checklist

Choosing the right heat press is a smart investment for success.

Final Checklist

✔ Stable temperature up to 180°C

✔ Adjustable pressure control

✔ Flat and strong platen

✔ Suitable size for your designs

✔ Reliable build quality

DTF Printing is simple when the right tools are used. A good heat press saves time, material, and customer complaints.

Product Suggestions (From DTFshop.in)

- DTF Pro Max Heat Press Machine

- DTF Heavy Duty Swing-Away Heat Press

- DTF Automatic Digital Heat Press

External References + Credits

Helpful reading sources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply