DTF Printing – Ultimate Guide for Gift Wrap & Bags

Table of Contents

DTF Printing on Gift Wrap and Bags

Introduction to DTF Printing

DTF Printing has quickly become a favorite method for customizing packaging materials like gift wrap and gift bags. Unlike screen printing, which needs plates and larger setups, DTF Printing works perfectly for short and long-run projects with bright colors and fine details. Many small business owners use it to upgrade their packaging without spending too much.

Whether someone sells handmade soaps, jewelry, or corporate gift hampers, adding customized gift wrap and bags creates a professional and memorable feel. DTF Printing helps you do that with consistency and durability.

Benefits for Gift Wrap and Bags

Using DTF Printing on packaging gives several advantages:

- Suitable for multiple surfaces: kraft paper, coated gift wrap, fabric bags, canvas bags, jute bags, and even non-woven material.

- Sharp and vibrant prints: gradients and small text appear clearly.

- Washable and scratch-resistant: lasts longer than vinyl stickers.

- Low setup cost: ideal for small businesses and event vendors.

For example, a boutique selling handmade candles switched from stickers to DTF prints on their paper bags. Customers noticed the difference because the new prints did not peel or fade.

Required Materials and Tools

Here’s what you need to start DTF Printing on gift wrap and bags:

- DTF Printer

- CMYK+White DTF Ink

- DTF Film

- Adhesive Powder

- Heat Press Machine

- Design Software

- High-quality materials make a major difference. Many professional printers prefer DTF Ink Premium from DTFshop.in, Cold Peel DTF Film Roll , and DTF Adhesive Powder – Fine Grade for consistent results. If you use reusable fabric gift bags, Cotton Canvas Tote Blank for DTF works great for practice.

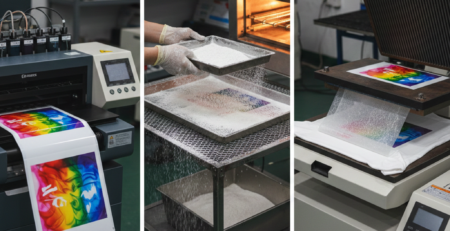

Step-by-Step Printing Process

Below is a beginner-friendly workflow:

- Create or import your design using PNG format.

- Print the design in CMYK first, then add the white layer.

- Sprinkle adhesive powder while the film is wet.

- Cure the film using a heat press hover or curing oven.

- Place the printed film on the gift wrap or bag.

- Press using recommended heat settings.

- Peel the film after cooling (cold peel works best for packaging).

DTF Printing gives consistent results even with detailed floral patterns or logos.

Design Tips and Best Practices

A few practical design tips:

- Use thick fonts to ensure visibility on kraft paper textures.

- Avoid pastel colors on brown gift bags; they may look dull.

- Add a drop shadow for premium-looking branding.

- Keep a margin around edges to avoid creasing during folding.

Most packaging experts on PrintIndustry.com recommend using high-contrast designs for strong visual impact.

Application Techniques

You can use DTF Printing in different ways:

| Packaging Surface | Result | Notes |

|---|---|---|

| Glossy gift wrap | Bright and vibrant | Use low pressure |

| Kraft paper bags | Premium luxury look | Add extra white ink |

| Canvas bags | Sharp and crack-free | Best retail resale option |

| Non-woven bags | Smooth and durable | Perfect for corporate gifts |

For bulk production, prepare several printed films and apply them one after another. It speeds up workflow and keeps print quality uniform.

Heat Press Settings

Below are working settings that most printers use for packaging materials:

| Material | Temperature | Time | Pressure | Peel |

|---|---|---|---|---|

| Paper bags | 140–150°C | 10–12 sec | Low | Cold |

| Glossy wrap | 135–145°C | 8–10 sec | Very low | Cold |

| Canvas/Fabric bags | 150–160°C | 12–15 sec | Medium | Cold |

Always use a protective sheet to avoid shine or scorching.

Durability and Care Instructions

DTF Printing holds up well when handled correctly:

- Store printed wrap flat to avoid scratching.

- For canvas bags, ironing on the backside increases print life.

- Avoid rubbing the design with chemicals.

- Bedroom closets or airtight storage keeps unsued prints fresh.

InkJetInsights.com found that DTF films maintain more than 85% color stability after months of storage when kept in cool and dry conditions.

Creative Ideas and Examples

Here are some ideas proven to work in real small businesses:

- Wedding gift bags with initials and event dates

- Birthday gift wrap with cartoon characters

- Craft store branding on paper bags

- Seasonal themes like Christmas, Diwali, and Valentine’s Day

- Baby shower and return gift packaging

People love personalized packaging because it makes simple gifts more thoughtful.

Conclusion and FAQs

DTF Printing opens the door to professional-level custom packaging without big investments. It works well on almost every gift wrap and bag surface, and the results look stylish, durable, and premium.

FAQs

Q1: Can DTF Printing work on glossy gift wrap?

Yes, just use lower pressure and peel after cooling.

Q2: Does the print fade on paper bags?

No, if applied correctly with good adhesive powder.

Q3: Is DTF better than vinyl for bags?

Yes — it doesn’t crack or peel and supports fine detail.

Q4: What is the cost per print?

Depends on size and design, but DTF usually costs less than screen printing for small runs.

Product Suggestions (from DTFshop.in)

- DTF Ink Premium

- Cold Peel DTF Film Roll

- DTF Adhesive Powder – Fine Grade

- Cotton Canvas Tote Blank for DTF

- DTF Heat Press Machine

External References + Credits

Credit: Information references from Fespa, PrintIndustry, InkJetInsights, and other public sources.

LEAVE A COMMENT