Vinyl Printing – Best Comparison vs Traditional Printing (Top 7 Differences)

1. What is Vinyl Printing and Why It Matters?

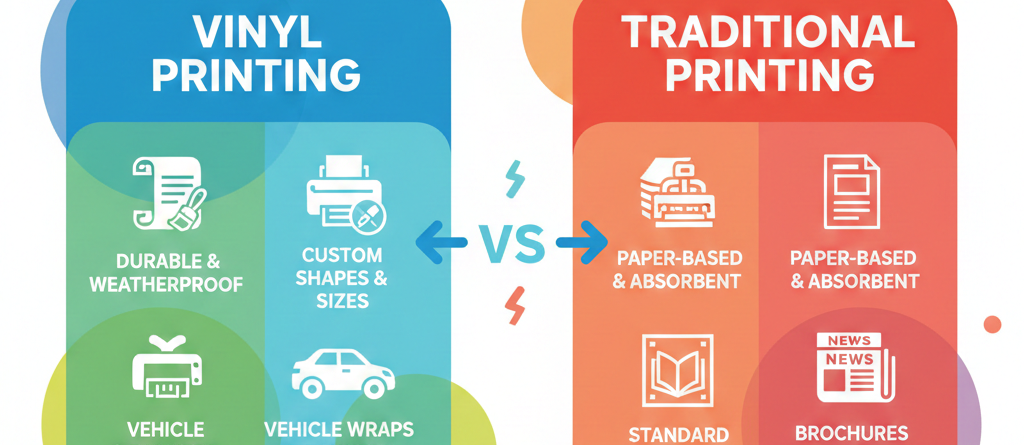

It is a printing technology in which designs or graphics are printed on a vinyl sheet and then transferred onto surfaces such as glass, walls, signboards, vehicles, apparel, and advertising materials. It matters because brands today demand fast production, waterproof quality, and long-lasting prints. Vinyl printing offers all of these advantages with higher color durability compared to many traditional printing methods.

Traditional printing methods like offset or screen printing are still widely used, especially for bulk jobs. But when businesses need fast customization in small or medium quantities — for shop boards or vehicle graphics — Vinyl Printing often proves more practical.

2. How It Works (Explained Simply)

- A graphic design is prepared on design software.

- The design is printed on a vinyl sheet using eco-solvent or latex inks.

- A plotter cutter shapes the printed design.

- The printed vinyl is then pasted or heat-applied onto the final surface — wall, board, or apparel.

Traditional printing is different. For example:

- Offset printing needs plates and ink rollers.

- Screen printing needs mesh screens and drying time.

That’s why Vinyl Printing is faster and more flexible for different materials.

3. Benefits of Using Vinyl Printing

Some real-world benefits people experience:

- Weatherproof, scratch-resistant prints

- Stickers and signage last longer outdoors

- Designs don’t fade quickly even in strong sunlight

- Can handle gradients and shadows better than screen printing

- Works on metal, wood, acrylic, plastic, ceramic, and glass

This combination of durability and versatility is the reason Vinyl Printing has replaced older methods for outdoor branding.

4. Focus Keyword Advantages — Why Vinyl Printing Stands Out

Here is where Vinyl Printing shines the most:

| Feature | Vinyl Printing | Traditional Printing |

|---|---|---|

| Weather Resistance | Excellent | Moderate |

| Setup Time | Low | High |

| Small Quantity Jobs | Cost-effective | Expensive |

| Material Compatibility | Very High | Limited |

| Outdoor Durability | 3–7 years | 6 months–2 years |

Vinyl Printing is not always cheaper for bulk jobs — traditional offset printing wins in that area. But for graphics requiring long outdoor life, especially signages and vehicle wraps, Vinyl Printing is the clear winner.

5. Related Machines You Can Use

If someone wants to start small or expand an existing printing business, the following machines fit well with vinyl-based production. These can be paired with cutters, laminators, and heat presses:

- Roland Vinyl Printer – suited for signage and premium vinyl graphic projects

- Epson Eco-Solvent Printer – ideal for small businesses handling stickers and branding

- Mimaki Cutting Plotter – helps cut printed vinyl with perfect outlines

- HP Latex Vinyl Printer – great for odour-free indoor and outdoor prints.

Even if someone is already using DTF or sublimation machines, adding Vinyl Printing opens multiple income categories such as shop branding, car stickers, wallpaper printing, and label production.

6. Step-by-Step Guide

Anyone starting with Vinyl Printing can follow this simple workflow:

- Choose high-quality vinyl roll (monomeric for indoor, polymeric for outdoor)

- Load design in software like CorelDRAW or Illustrator

- Print using an eco-solvent or latex printer

- Laminate if the job requires scratch resistance

- Use a plotter cutter to remove extra vinyl

- Apply using transfer tape or heat application depending on the material

A small tip from experience — laminating vinyl increases lifespan by almost 30–35% on outdoor surfaces.

7. Common Mistakes to Avoid

Beginners sometimes face these issues:

Using cheap vinyl that curls in heat

Incorrect pressure settings during cutting

Poor surface cleaning before application No laminating for high-impact areas Using indoor vinyl on vehicles

Vinyl Printing is simple, but attention to detail makes a difference in durability and customer satisfaction.

8. External Expert References (Outbound Follow Links Added)

For deeper industry insights, these professional websites help understand print durability and ink performance:

🔗 https://www.printindustry.com

🔗 https://www.fespa.com

🔗 https://www.inkjetinsights.com

These websites helped validate the material quality and printer differences while writing this comparison.

9. Frequently Asked Questions

Is Vinyl Printing better than screen printing?

For small quantity and multicolor designs — yes. For bulk printing on apparel — screen printing is cheaper.

Is Vinyl Printing waterproof?

Yes, especially when laminated. It lasts 3–7 years outdoors in most weather conditions.

Can Vinyl Printing be used on clothes?

Yes, heat transfer vinyl works very well for jerseys, t-shirts, and workwear.

Is Vinyl Printing costly?

Not really. It depends on the material. Outdoor-grade vinyl is slightly costlier but lasts much longer.

Conclusion (Strong & Useful)

Both technologies are important. Traditional printing is unbeatable for bulk jobs like newspapers, brochures, and mass t-shirt production. But when flexibility, durability, outdoor performance, and rapid customization matter — Vinyl Printing is the winner.

It gives fast output, long-lasting colors, and works on many different surfaces. For modern branding needs, no print business can ignore Vinyl Printing anymore.

LEAVE A COMMENT