UV 3D Printing Breakthroughs: New Technologies Transforming Crystal UV 3D Printing in 2026

Table of Contents

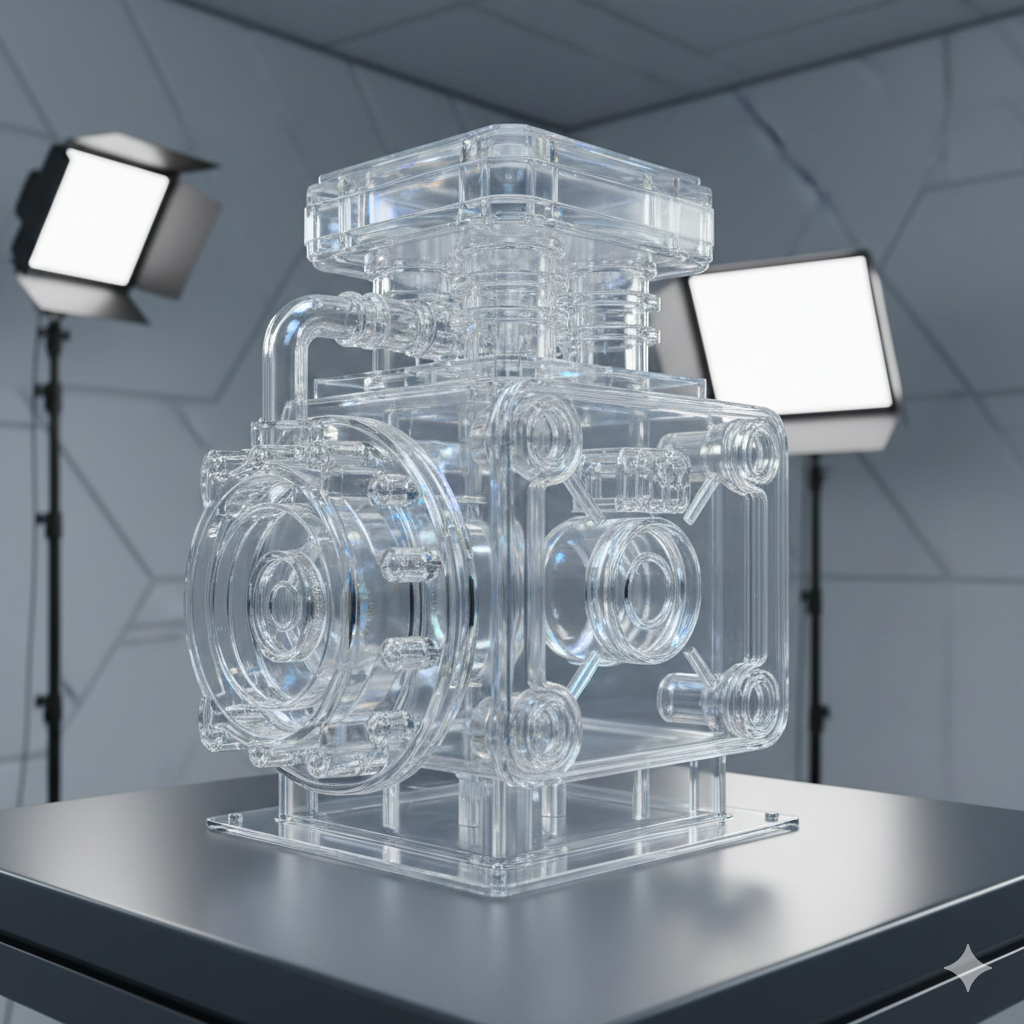

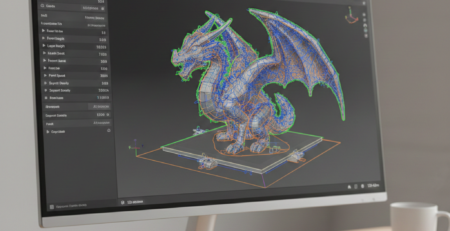

UV 3D Printing has changed how transparent and high-detail objects are made. From custom signage to industrial prototypes, this method offers clarity, strength, and fine surface finish. In crystal UV 3D printing, UV light cures liquid resin layer by layer. The result is sharp edges, smooth surfaces, and glass-like transparency.

In 2026, UV 3D Printing is not just about looks. It is about speed, accuracy, and smart material use. Many print shops now use UV-based systems to meet growing demand for premium-quality parts. Small studios and large factories both benefit from these advances.

This article explains where the technology stands today and what new changes are shaping the future. The focus stays practical, clear, and easy to follow.

Current State of Crystal UV 3D Printing

Today, UV 3D Printing mainly relies on SLA and DLP technologies. These systems use UV light to cure resin inside a build area. They are known for fine details and smooth output.

Most users already enjoy benefits like:

- High resolution

- Strong adhesion between layers

- Excellent transparency after polishing

However, there are limits. Print speed can be slow for large parts. Resin costs are high. Post-processing still takes time.

Many print professionals use tools like the UV DTF Flatbed Printer 6090 from DTFshop.in for hybrid jobs where flat UV printing and 3D effects meet. Accessories such as a UV LED Curing Lamp (395nm) help improve surface hardness during finishing.

The current state is stable, but the demand for faster and smarter systems is pushing innovation.

Emerging Technologies in 2026

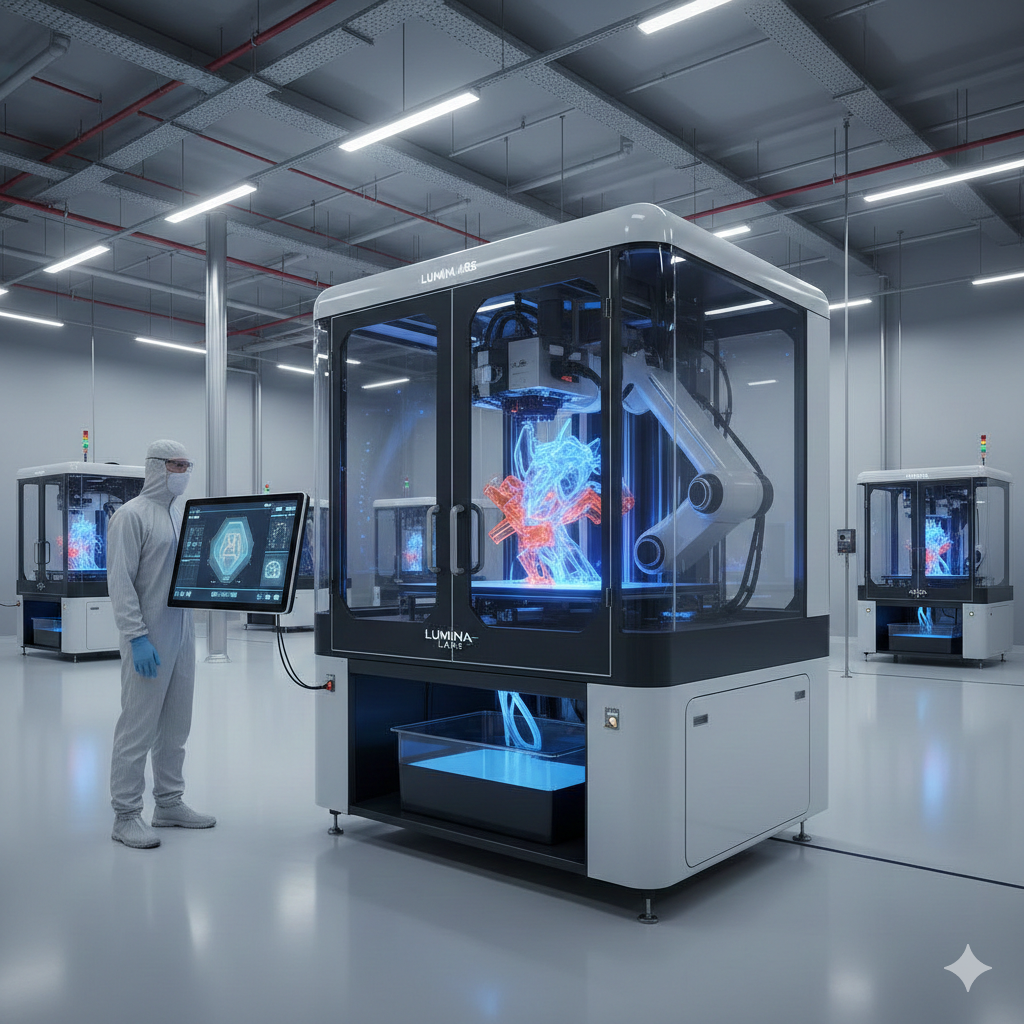

In 2026, UV 3D Printing is moving beyond traditional layer-by-layer limits. New systems focus on speed, material intelligence, and multi-function printing.

Key technology shifts include:

- Continuous curing instead of step printing

- AI-assisted resin behavior control

- Multi-material printing in one job

These upgrades reduce waste and improve consistency. They also allow new design freedom, especially in crystal-clear and colored transparent parts.

High-Speed Stereolithography Advances

High-speed SLA is one of the biggest upgrades in UV 3D Printing. New machines use stronger light engines and oxygen-permeable films. This allows continuous resin curing.

Benefits include:

- Up to 3x faster print times

- Less layer separation

- Better optical clarity

For example, signage makers printing 3D logos now finish jobs in hours instead of days. Combined with crystal clear UV resin from DTFshop.in, the surface finish improves with less sanding.

Practical tip: Faster printing still needs cooling control. Stable room temperature keeps resin behavior consistent.

Volumetric Printing Innovations

Volumetric printing is a major step forward. Instead of layers, UV light cures the whole object at once inside a resin vat.

This method:

- Removes layer lines

- Produces true crystal transparency

- Cuts printing time dramatically

Although still costly, early adopters in medical and optical fields see strong results. Research papers on ResearchGate show volumetric UV curing improves internal strength and clarity.

This technology may soon move from labs to commercial UV 3D Printing setups.

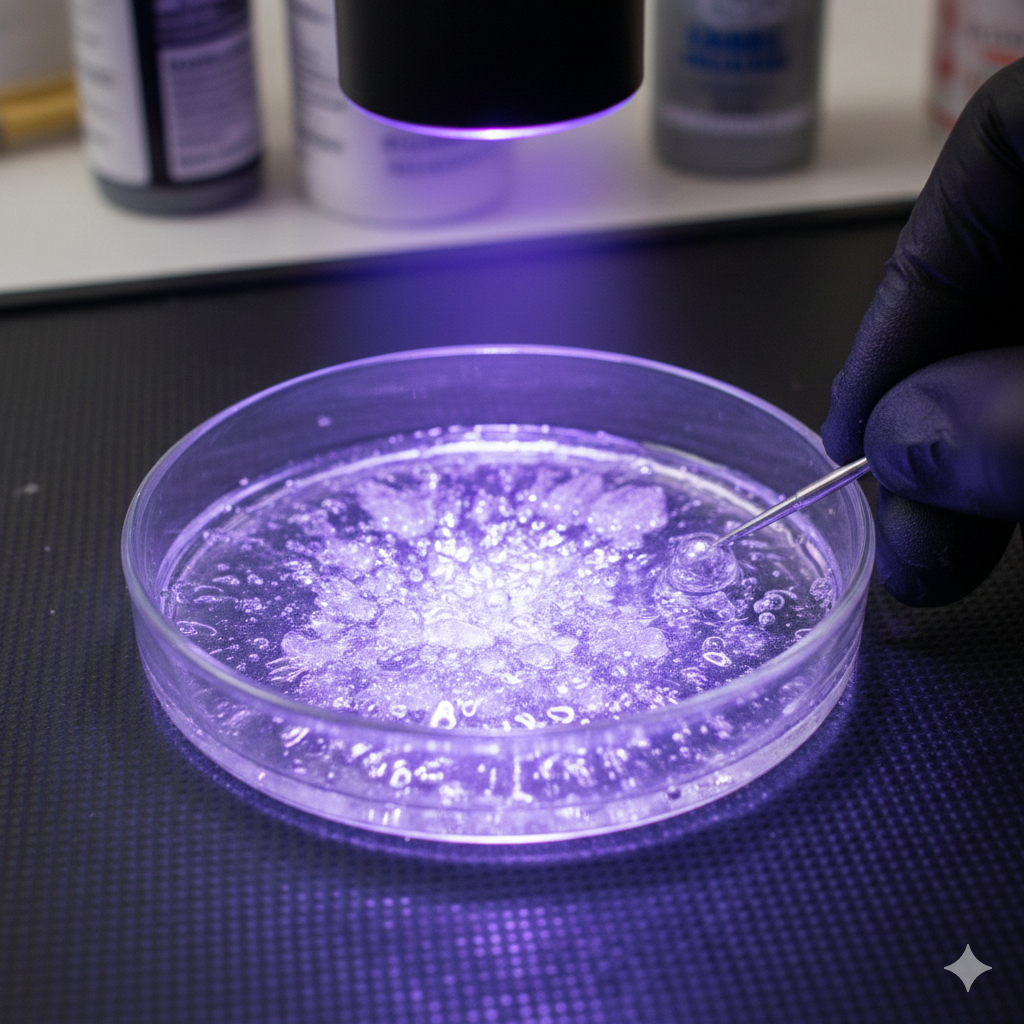

AI-Driven Resin Optimization

AI is now part of UV 3D Printing workflows. Smart software adjusts exposure, curing time, and light intensity based on model shape.

Advantages include:

- Less resin waste

- Fewer print failures

- Consistent transparency

AI systems also recommend resin blends. This helps when using flexible or impact-resistant materials.

Many users pair AI settings with tools like an automatic UV resin mixer to maintain uniform resin quality during long print runs.

This reduces human error and saves material costs.

Multi-Material UV Formulations

Multi-material UV 3D Printing allows different resins in one print. Transparent, flexible, and rigid zones can exist together.

Use cases include:

- Transparent housings with soft seals

- Decorative items with embedded color layers

- Functional prototypes with moving parts

New resin cartridges switch automatically during printing. When combined with UV DTF PET film rolls from DTFshop.in, surface decoration becomes easier after printing.

This technology helps brands create complex designs without assembly.

Cold-Spray UV Hybrids

Cold-spray UV hybrids mix additive printing with surface coating. A cold-spray system applies material, then UV light cures it instantly.

Benefits:

- No heat damage

- Strong layer bonding

- Ideal for delicate crystal parts

This method is gaining attention in electronics and decorative panels. PrintIndustry.com reports growing use in premium product packaging.

It also reduces post-processing since surfaces come out smooth and sealed.

Key Benefits and Performance Gains

By 2026, UV 3D Printing offers clear performance improvements:

- Faster production cycles

- Better optical clarity

- Lower resin consumption

- Improved mechanical strength

Print shops using modern UV systems report higher customer satisfaction. Crystal prints now rival injection-molded parts in appearance.

Practical tip: Always test small samples when switching resins. Minor changes affect transparency.

Industry Applications and Case Studies

UV 3D Printing is now common in:

Signage and Branding

3D logos, illuminated letters, and display elements use crystal UV prints for premium appeal.

Medical Devices

Transparent surgical guides and dental models rely on accuracy and clarity.

Consumer Products

Luxury packaging inserts and decorative parts use UV clarity to stand out.

A case study shared by Fespa.com highlights a European sign maker reducing lead time by 40% using high-speed UV 3D Printing systems.

Challenges and Future Outlook

Despite progress, challenges remain:

- High equipment cost

- Resin recycling issues

- Skilled operator requirement

However, costs are slowly dropping. Training resources are expanding. Environmental-friendly resins are under development.

The future of UV 3D Printing looks stable and promising. The focus will be on automation and sustainable materials.

Conclusion and Adoption Roadmap

UV 3D Printing in 2026 is faster, smarter, and more flexible. Crystal-clear results are now achievable at scale.

For beginners:

- Start with standard SLA systems

- Use reliable UV resins

- Focus on proper curing

For professionals:

- Explore AI-driven settings

- Test multi-material printing

- Invest in post-processing tools

Step-by-step adoption reduces risk and improves output quality. With steady learning, UV 3D Printing becomes a strong long-term investment.

Product Suggestions (Used Naturally in Context)

External References + Credits

Helpful resources:

Credit: Information references from Fespa, PrintIndustry, and other public sources.

Leave a Reply