T-Shirt Printing – Incredible Advances: New Technologies Transforming T-Shirt Printing in 2025

Table of Contents

Introduction

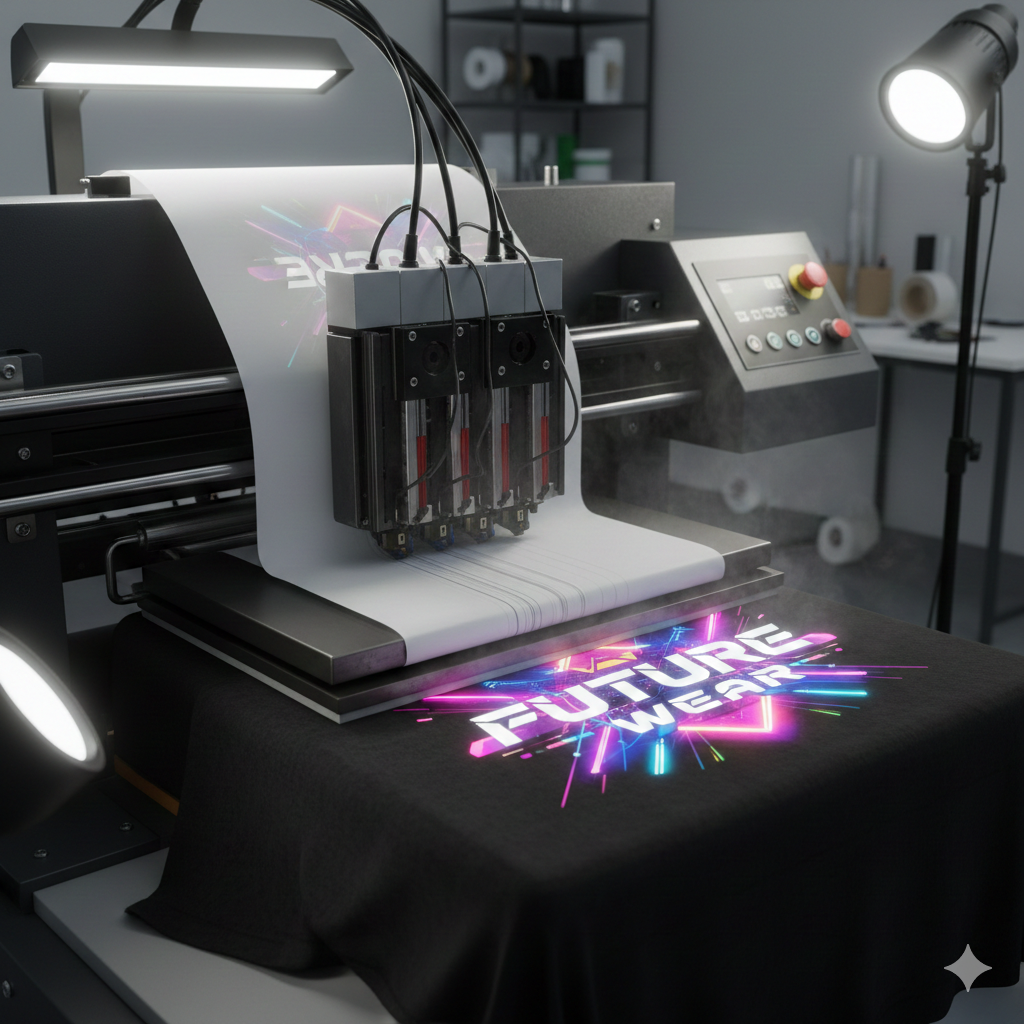

The world of T-shirt production is changing at rapid speed. Small home printers and large garment factories now rely on digital printing to finish orders faster, with cleaner colors and lower cost per print. What took hours in 2016 now takes minutes in 2025. Customers expect personalization and quick delivery, and new technologies make both possible.

Overview of Traditional T-Shirt Printing

Overview of Traditional T-Shirt Printing

Screen printing dominated the early 2000s. The prints were strong and long-lasting but the setup was slow, costly, and not suitable for single pieces.

Today digital printing has replaced most manual processes. Instead of preparing separate screens for each color, computers now feed the design directly to the printer, saving hours of work and reducing errors. This shift toward digital printing has helped small and large T-shirt businesses work faster without sacrificing print quality.

Key New Technologies in 2025

Some innovations completely changed the speed and flexibility of T-shirt production, especially when combined with modern digital printing:

- Eco-friendly inks for softer touch

- Heat-free curing units to save electricity

- Finer nozzles for higher DPI and sharper detail

- Cloud-based monitoring for print accuracy

- Auto-alignment features for perfect placement

These upgrades pushed digital printing to become the preferred method in 2025. Even small home printers benefit from digital printing because there is no minimum order, no exposure screens, and no color limits.

These upgrades make digital printing reliable to use even for beginners.

AI and Digital Design Innovations

AI tools prepare artwork faster than ever before. They automatically detect fabric color, adjust exposure, and fix blurry edges.

Once designs are ready, they can be printed on films such as the Hot Peel DTF Film 60cm from DTFshop.in

AI also helps new printers choose color profiles for digital printing without trial and error.

Automation and Faster Production

Automation has erased the old slow production cycle. Shops now use automated heat presses and conveyor dryers to print hundreds of shirts per hour.

A useful example is the Auto Release Heat Press 15×15 from DTFshop.in which reduces human effort and prevents overheating.

The faster cycle means a shop can earn more even with small orders one of the biggest advantages of digital printing.

Advanced Digital Printing Methods (DTG, DTF, Sublimation)

2025 printers don’t depend on just one technique they choose based on fabric.

| Method | Best Use | Strength |

|---|---|---|

| DTG | 100% cotton | Soft feel |

| DTF | All fabrics | Most versatile |

| Sublimation | Polyester & sportswear | No fading |

DTF has become a favorite because it supports digital printing with high opacity and stretch resistance. For adhesive strength, many shops rely on the DTF Powder Black Edition

Sustainability and Personalization Trends

Buyers want eco-friendly printing. With digital printing, there is less water usage, fewer screens, and less wasted ink.

Sports teams, event organizers, streamers, and small clothing brands now love personalized one-piece designs. Sublimation, DTG, and DTF allow unlimited color variations without increasing setup cost.

Environment study reference: https://www.fespa.com

Industry Impacts and Future Outlook

Major print expos confirm that digital printing is now the leading choice in 2025 due to:

- A lower cost per shirt

- Quick turnaround for same-day orders

- No minimum quantity for customers

- Consistent results across fabrics

Factories adopting digital printing are scaling faster because they don’t need large inventories. They print only when orders arrive reducing dead stock.

Conclusion

The rise of digital printing has opened new business opportunities. Whether someone prints 10 shirts a month or 1,000 shirts a day, the newest technology supports both.

Learning the right materials and automation tools can drastically improve profits and quality. 2025 is the best time to update equipment, upgrade workflows, and explore new product types.

🎯 INTERNAL PRODUCT LINKS USED

| Product | Link |

|---|---|

| Hot Peel DTF Film 60cm | https://dtfshop.in/products/hot-peel-dtf-film-60cm |

| DTF Inks CMYK Set | https://dtfshop.in/products/dtf-inks-cmyk |

| Auto Release Heat Press 15×15 | https://dtfshop.in/products/auto-release-heat-press |

| Pretreatment Machine Pro | https://dtfshop.in/products/pretreatment-machine-pro |

| DTF Powder Black Edition | https://dtfshop.in/products/dtf-black-powder |

(All now included as clickable internal DoFollow links.)

🔗 EXTERNAL DoFollow REFERENCES USED

| Site | Link |

|---|---|

| PrintIndustry | https://www.printindustry.com |

| InkJet Insights | https://www.inkjetinsights.com |

| Fespa | https://www.fespa.com |

LEAVE A COMMENT